Environment-friendly straw recovery treatment device

A recycling and environmental-friendly technology, applied in grain processing, solid separation, filtration and screening, etc., can solve the problems of lower production efficiency and crushed particles that cannot meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

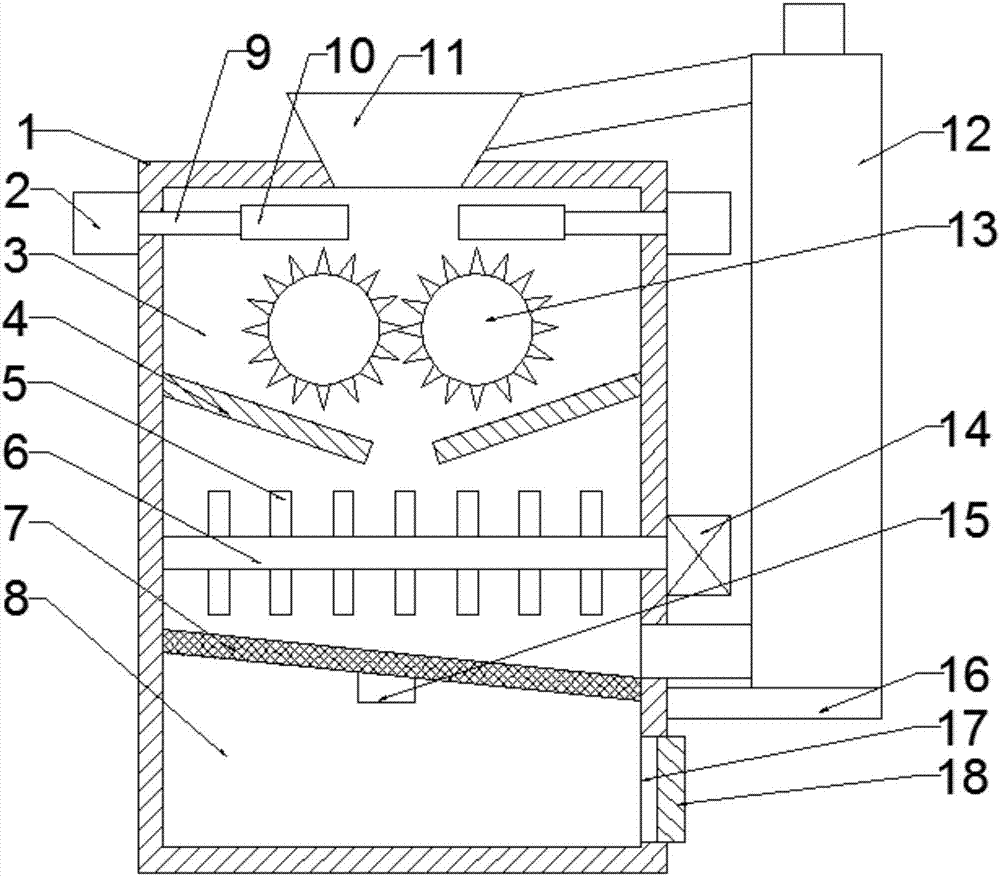

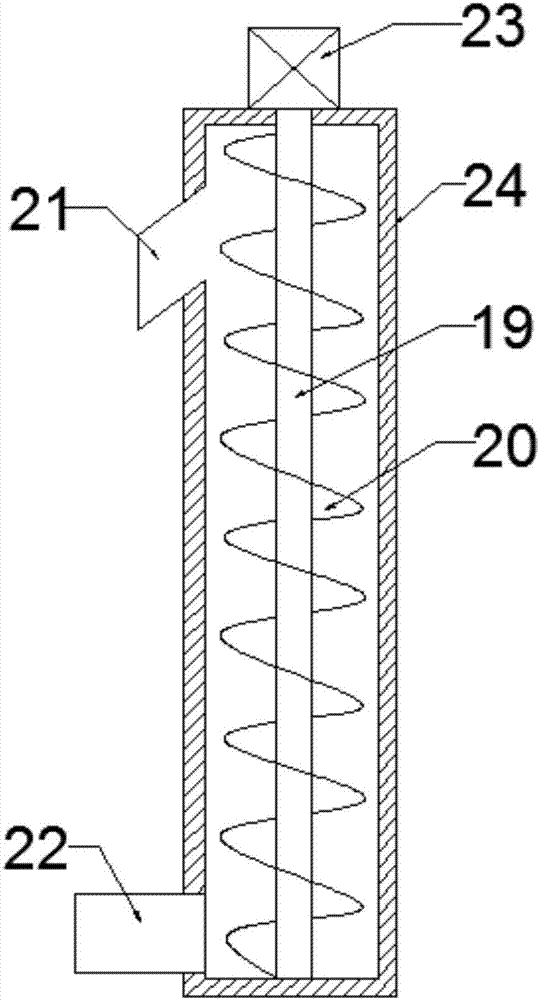

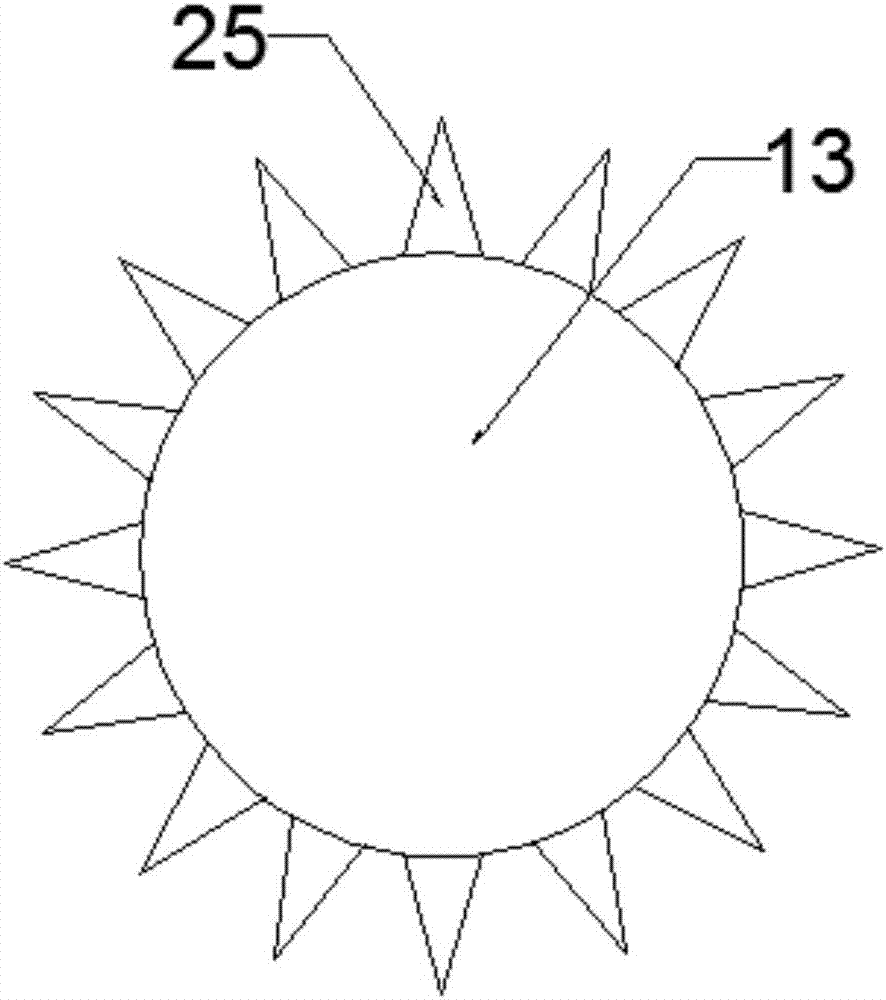

[0016] see figure 1 , this embodiment provides an environment-friendly straw recycling device, including a housing 1, a cylinder 2, a crushing chamber 3, a cutting plate 4, a crushing blade 5, a rotating shaft 6, a screen 7, a feeding chamber 8, a telescopic Shaft 9, material retaining block 10, feed hopper 11, lifting device 12, crushing roller 13, rotating motor 14, vibrator 15, fixed plate 16, discharge port 17 and discharge baffle plate 18; The hopper 11 is arranged in the center of the upper end of the housing 1, and the lower end of the feed hopper 11 is provided with a stopper block 10; two stopper blocks 10 are provided, and the stopper block 10 is connected to the telescopic shaft 9; the telescopic shaft 9 runs through The casing 1, the telescopic shaft 9 is connected to the cylinder 2; the cylinder 2 is provided with two, which are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com