Lifting type loading device

A lifting and feeding technology, applied in the field of feeding, can solve the problems of uneven manual feeding, manual scraping, wasting time, etc., and achieve the effect of reducing manual labor intensity, uniform feeding, and convenient feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

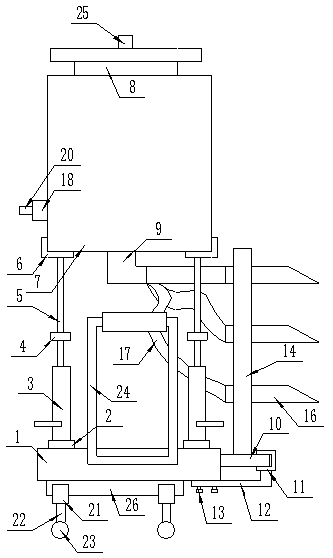

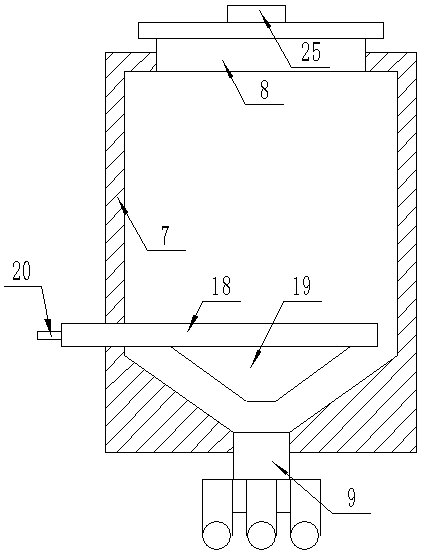

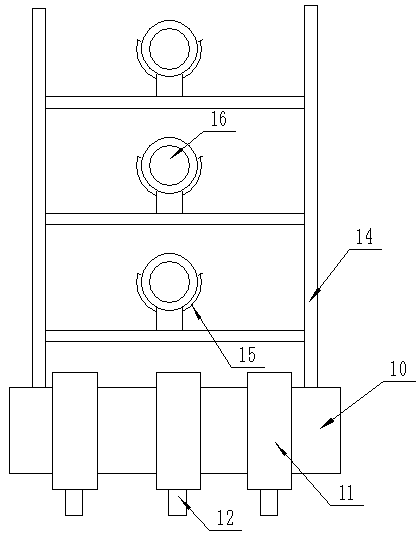

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a lifting feeding device includes a strip-shaped bearing base 1, the upper surface of the strip-shaped bearing base 1 is provided with a lifting and feeding mechanism, and the lower surface of the strip-shaped bearing base 1 is provided with a moving mechanism, the lifting and feeding mechanism consists of two sets of support bases 2 fixedly connected to the four corners of the upper surface of the bar-shaped bearing base 1, a hydraulic push rod 3 arranged on the upper surface of each support base 2, and set on each The support frame 4 on the push end of the hydraulic push rod 3, the support column 5 embedded in the upper surface of each support frame 4, the load-bearing gasket 6 set on the upper end surface of each support column 5, and the two sets of load-bearing gaskets 6 The strip-shaped material storage box body 7 on the upper surface, the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com