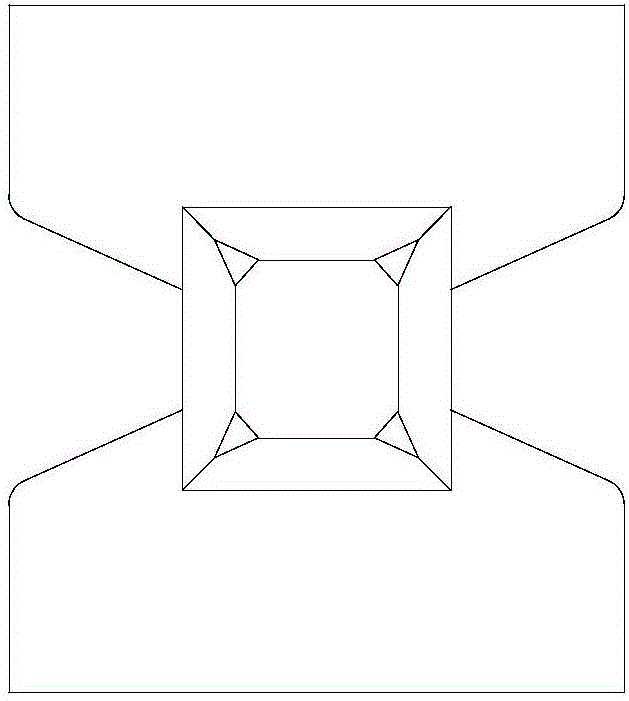

Forming mold for block in shape of torsional Chinese character 'wang'

A technology of forming molds and twisting king characters, which is applied in the direction of molds, mold trays, mold panels, etc., can solve problems such as inability to move in narrow spaces, cumbersome mold removal operations, and increased construction costs, achieving fast and convenient locking and reducing costs , The effect of facilitating the construction of formwork and formwork removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

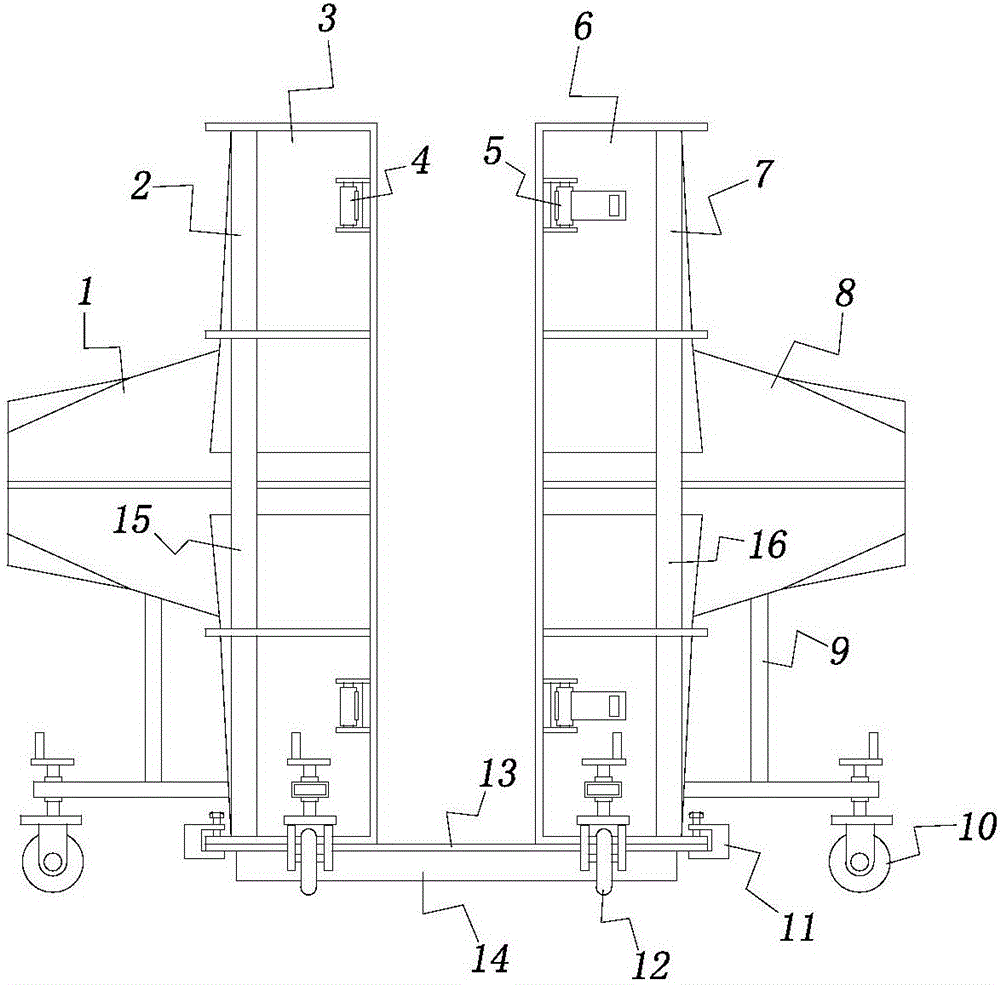

[0022] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

[0023] See figure 2 , The twisted king block forming mold of the present invention includes a support 14 and a bottom plate 13 located at the top of the support 14 , on which a first mold shell 3 and a second mold shell 6 opposite and movable are arranged on the bottom plate 13 .

[0024] Both the shells of the first formwork 3 and the second formwork 6 are welded by metal plates, and a slit wing plate with a plurality of connection holes is arranged at the edges where the two are connected. The tops of both are provided with top flanges, and the bottoms are provided with bottom flanges; after the first formwork 3 and the second formwork 6 are butt-jointed and fastened, a pouring chamber for the Twisted King block body is formed inside.

[0025] The first protruding portion 1 is provided on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com