Electric injection molding control device of injection molding machine

A control device and injection molding machine technology, which is applied in the field of injection molding machines, can solve problems such as software cannot see it, and achieve the effect of improving the accuracy of injection molding control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

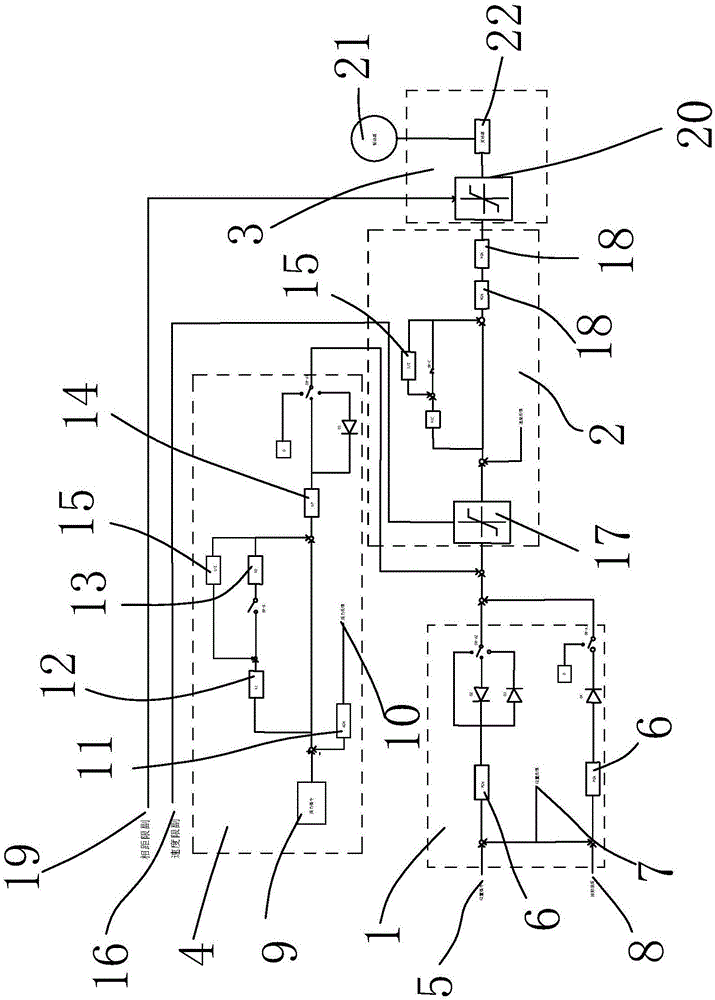

[0012] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0013] In the figure, position loop control module 1; speed loop control module 2; current loop control module 3; pressure loop control module 4; position input command terminal 5; position amplifier 6; position feedback signal terminal 7; injection molding pressure holding command terminal 8; Pressure command input terminal 9; pressure feedback terminal 10; pressure amplifier 11; integral control constant 12; differential control constant 13; proportional control constant 14; Z transformation control constant 15; speed limit secondary terminal 16; speed limit secondary device 17; speed amplifier 18 ; phase moment limiting secondary terminal 19 ; phase moment limiting secondary device 20 ; driver 21 ; frequency converter 22...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap