Rotation water outlet bottle cap

A bottle cap and water outlet technology, applied in the field of water outlet bottle caps, can solve the problems of difficult processing, unsmooth water outlet, complex structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments are described below with reference to the drawings.

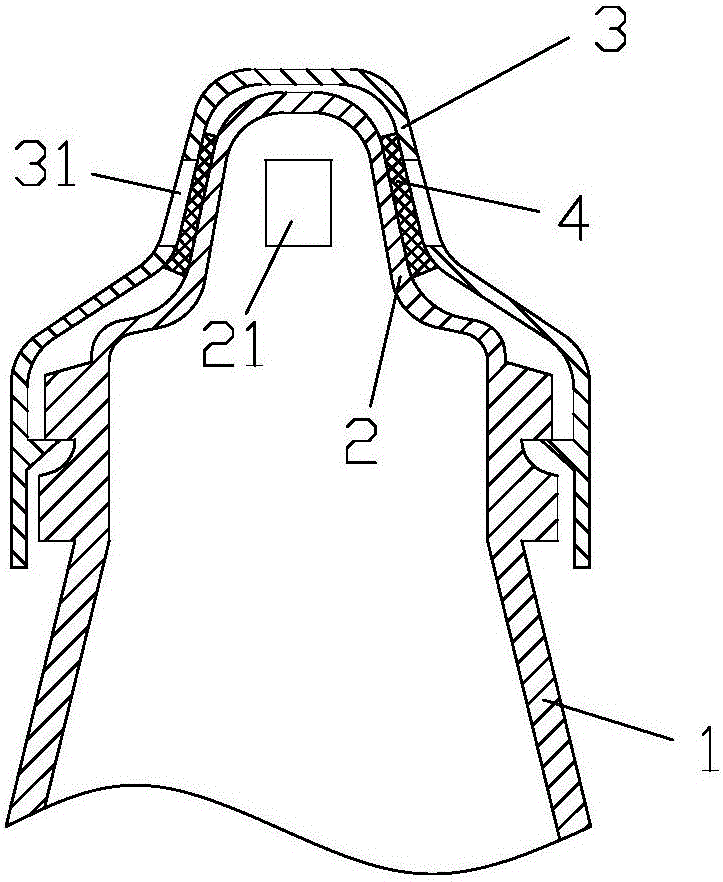

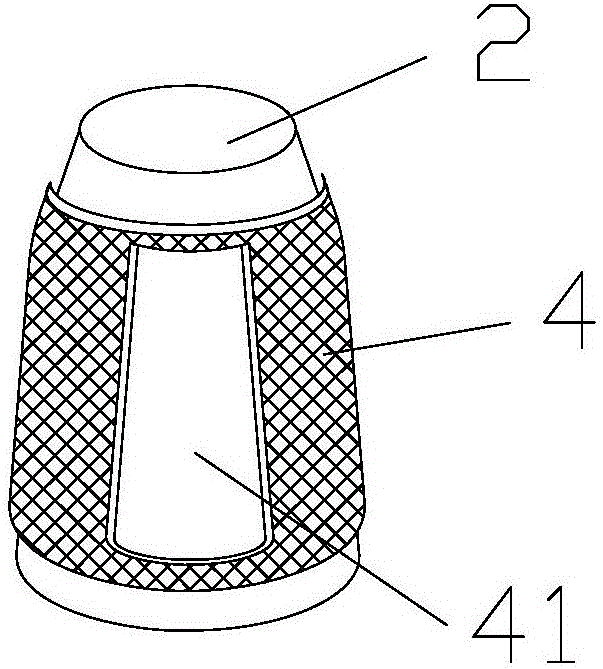

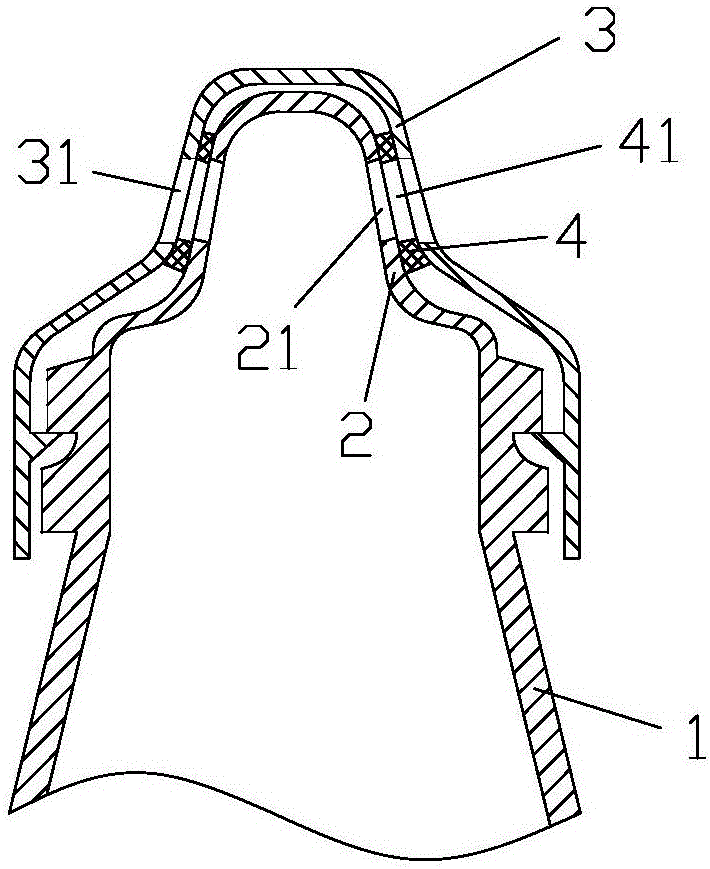

[0014] Such as figure 1 As shown, a rotating water bottle cap is suitable for a liquid packaging bottle. The rotating water bottle cap includes a bottle body 1, an inner cap 2, an outer cap 3 and a connection between the inner cap 2 and the outer cap 3. The seal 4 between them; the inner cover 2 is arranged at the liquid outlet of the bottle body 1, and the inner water outlet 21 is arranged on the inner cover 2, and the inner water outlet 21 can make the liquid in the bottle body 1 flow out; the outer cover 3 is rotatable Set outside the inner cover 2; the outer cover 3 is provided with an outer water outlet 31, the position of the outer water outlet 31 corresponds to the position of the inner water outlet 21, so that after the outer cover 3 is rotated, the inner water outlet 21 can be docked with the outer water outlet 31 , so that the liquid in the bottle body 1 can flow out through the docking of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com