Locating mechanism and lamination stacking machine provided with locating mechanism

A positioning mechanism and positioning arm technology, which is applied in the stacking, transportation and packaging of objects, can solve the problem of inaccurate battery cell positioning, and achieve the effects of smooth movement, good positioning and high power controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

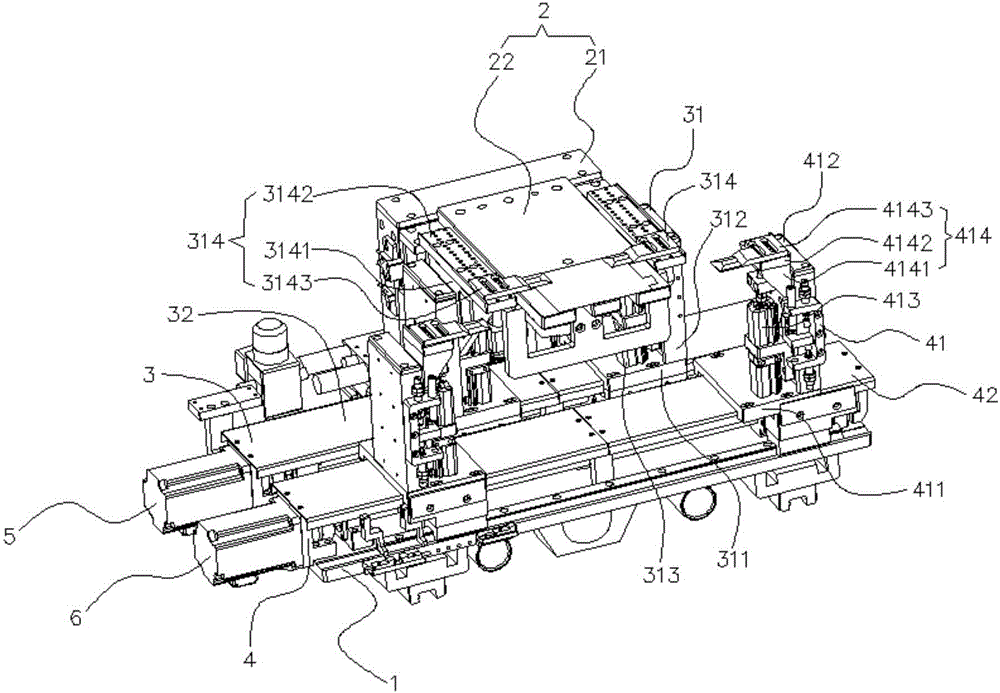

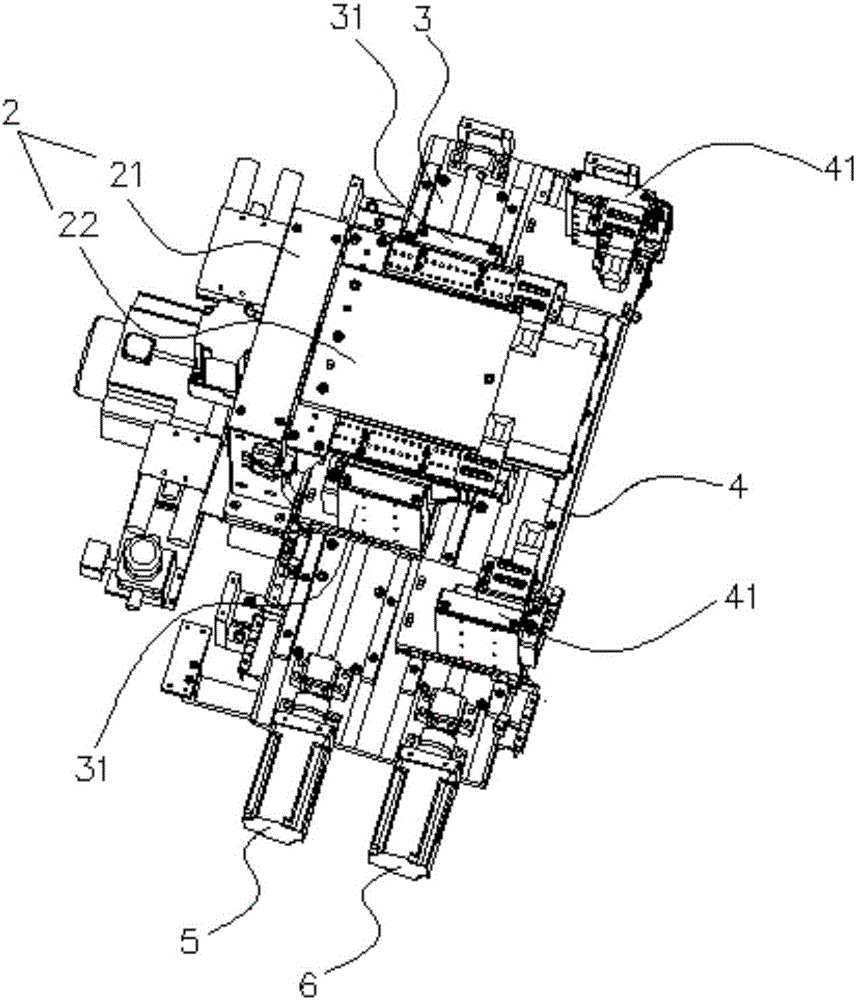

[0041] Such as figure 1 and figure 2 As shown, this embodiment provides a positioning mechanism 400 for accurately positioning and fixing a sheet (the sheet in this embodiment is specifically a battery sheet), and the positioning mechanism 400 includes a base 1 and a loading platform 2 , a first positioning assembly 3 , a second positioning assembly 4 , a first servo motor 5 and a second servo motor 6 .

[0042] The upper side of the base body 1 is a flat mounting surface for other structures to be installed and fixed, and the lower side has a plurality of connecting pieces for connecting and fixing with the tooling platform 100 .

[0043] The loading platform 2 is usually a steel frame structure, including a mounting portion 21 fixed to the base 1 and a horizontal plate 22 connected to the upper end of the mounting portion 21 . Wherein, the horizontal plate 22 is used to place the battery slices. In this embodiment, in order to ensure that the battery slices do not move si...

Embodiment 2

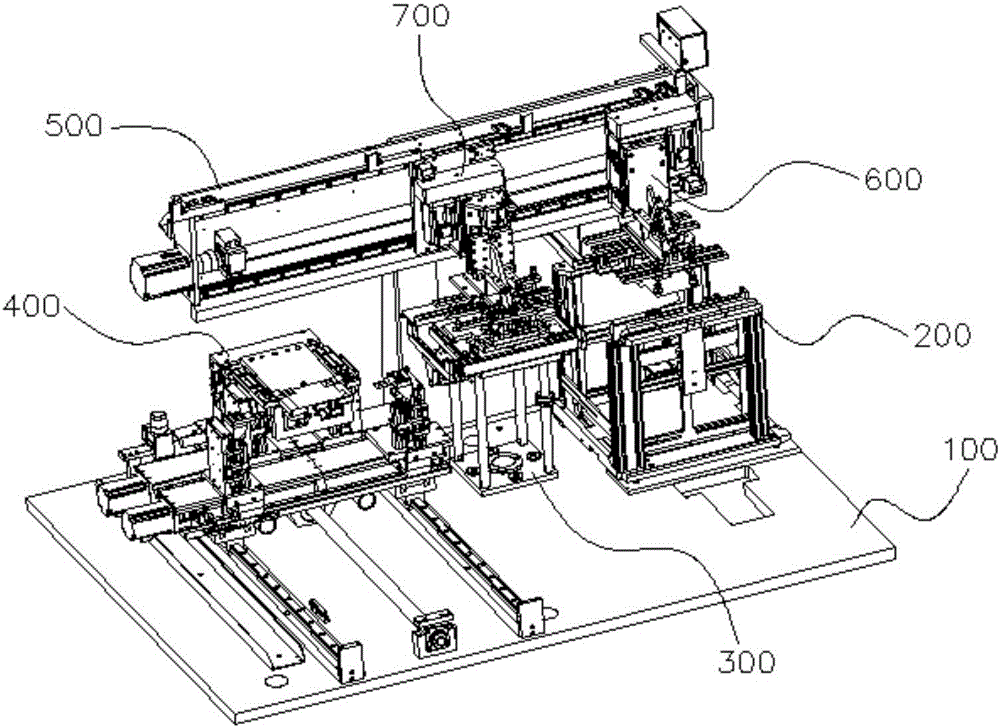

[0053] Such as image 3 As shown, this embodiment provides a stacking machine, including the positioning mechanism 400, the tooling platform 100, the sheet storage mechanism 200, the pre-positioning mechanism 300, the transmission mechanism 500, and the first sheet taking mechanism 600 as described in the first embodiment. And the second film taking mechanism 700, wherein:

[0054] The tooling platform 100 is made of steel with high hardness and strength, and is placed horizontally on the ground.

[0055] The sheet storage mechanism 200 has a bottom plate fixed on the tooling platform 100, and is respectively vertically fixed to the front frame and the rear frame at the front and rear ends of the bottom plate, and is connected and fixed to the front frame and the rear frame. Box left and right bezels. A plurality of sheets can be stacked neatly and evenly in the sheet storage mechanism 200. In this embodiment, the sheets refer to battery sheets. Of course, in other embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com