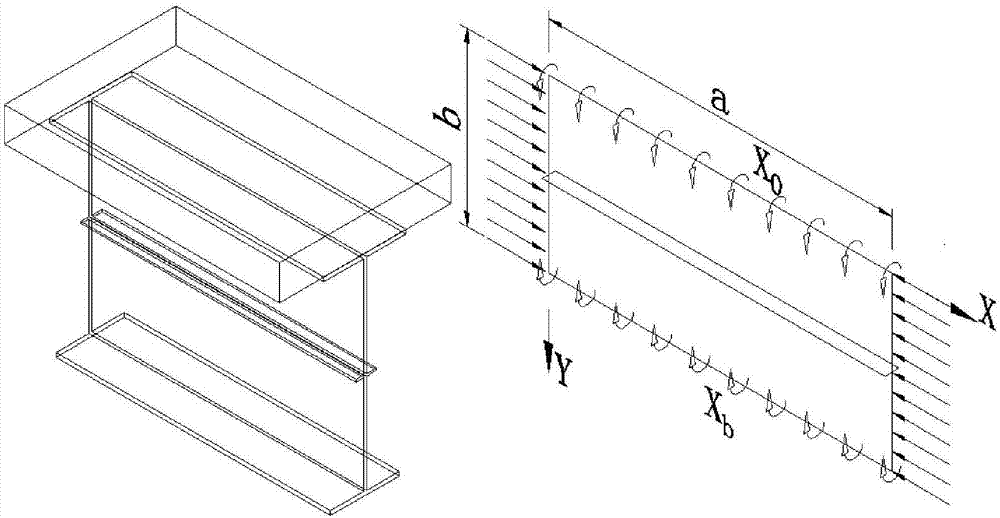

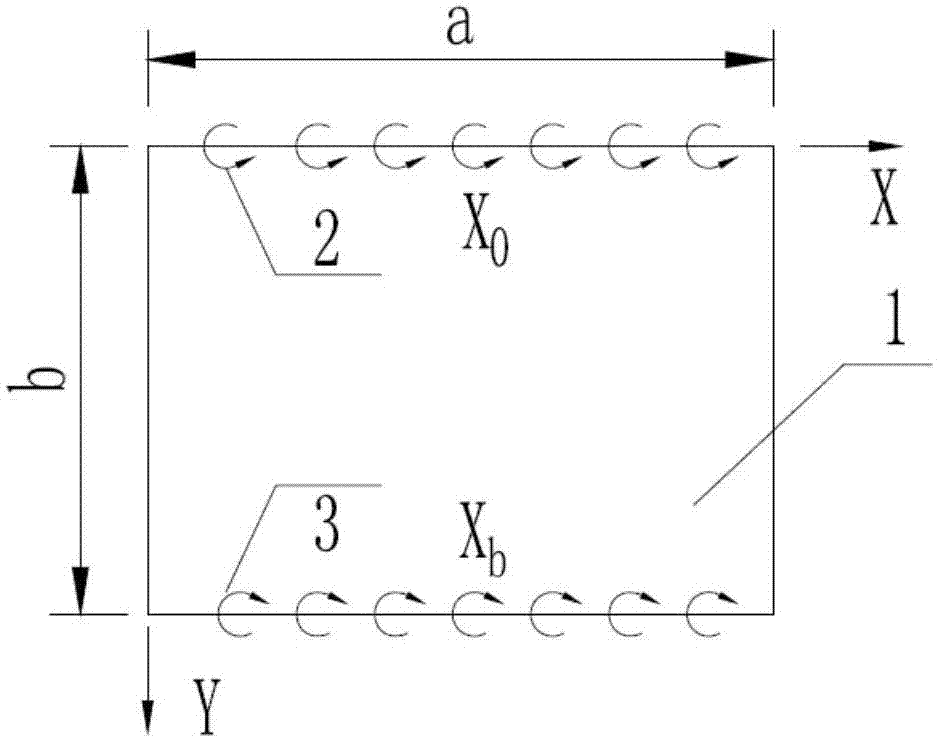

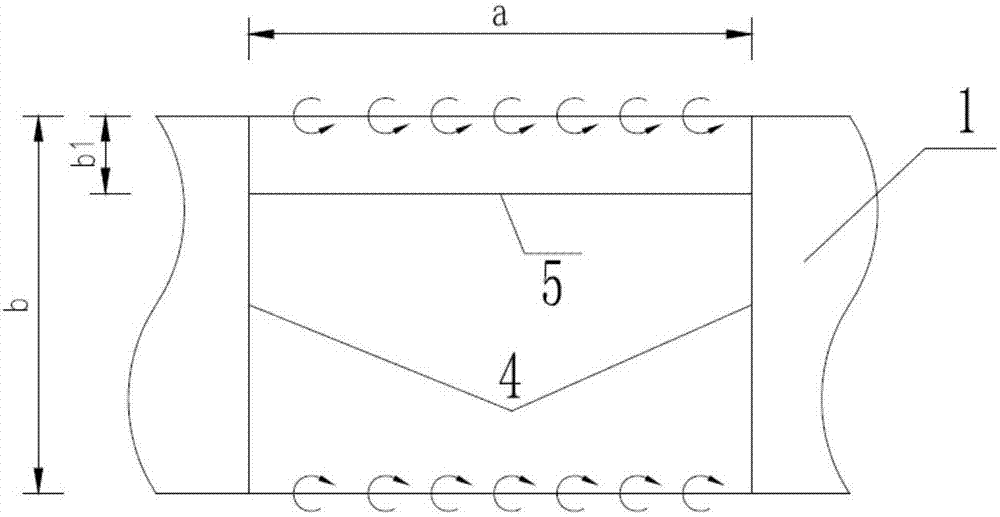

Method for Setting Longitudinal Stiffeners of High Web Plates of Steel-Concrete Composite Beams with Boundary Elastic Rotation Constraints

A technology of rotational constraints and composite beams, applied in bridge construction, bridges, bridge materials, etc., can solve problems such as high web error and high web stiffening design influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

[0075] A method for setting longitudinal stiffeners of steel-concrete composite beams with high webs bounded by elastic rotation constraints. Firstly, the displacement function equation and boundary conditions with elastic rotation constraints are established, and the stiffening under two states of rigid stiffening and flexible stiffening is derived based on the energy method. The formula for calculating the buckling stress of ribs is obtained to obtain the formula for calculating the critical stiffness of longitudinal stiffeners bounded by elastic rotation constraints; then, considering the principle of external force work and minimum potential energy, a formula for calculating the critical buckling stress of non-uniform compression plates under elastic rotation constraints is proposed; Finally, according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com