Paint applicator

An applicator and paint technology, applied in the direction of construction and building structure, can solve the problems of wasting paint, wasting time, and limited paint quantity, and achieve the effect of avoiding paint waste, smearing evenly, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

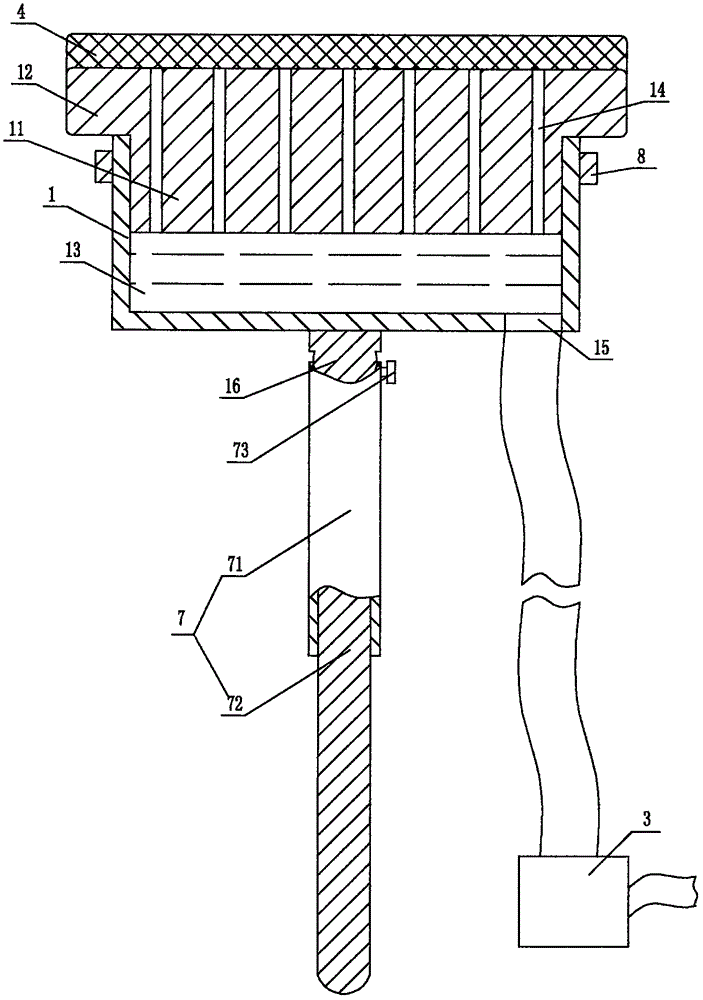

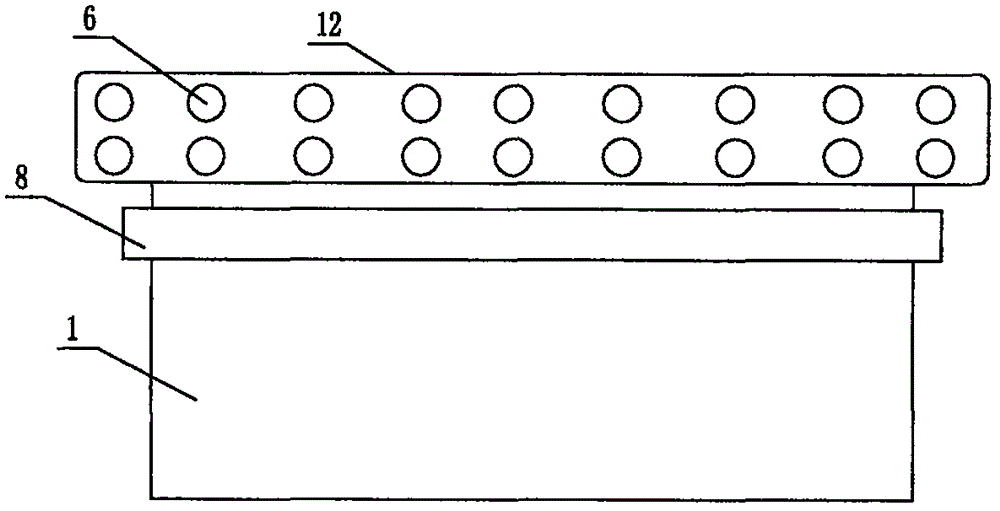

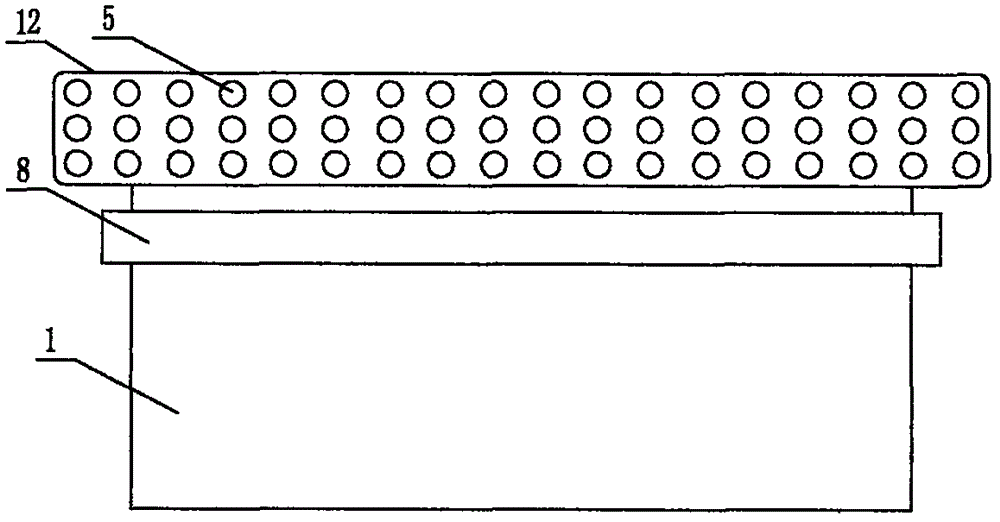

[0015] Such as figure 1 Shown, this paint applicator comprises the box body 1 of top opening, and the bottom of box body 1 is provided with telescopic rod 7, and telescopic rod 7 comprises upper rod 71 and lower rod 72, and the bottom of upper rod 71 is provided with cavity, and lower rod The top of 72 is screwed in the above-mentioned cavity, and this structure is convenient to adjust the length of telescoping rod 7, and then adjusts to smear height. The upper end of the upper rod 71 is provided with a circular clamping cavity, and the lower surface of the casing 1 is provided with a rotating ball 16 that is rotatably connected to the circular clamping cavity, and the matching structure between the rotating ball 16 and the circular clamping cavity is In the prior art, this structure can make the box body 1 rotate at multiple angles, and a locking bolt 73 is provided between the circular clamping cavity and the rotating ball 16, and the box body 1 can be fixed by the locking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com