Stable super-high observation tower for measurement in prefabricating of segmental beams

A stable, segmental beam technology, applied in towers, building types, buildings, etc., can solve the problems of poor measurement environment, low matching accuracy, unstable instruments, etc., and achieve small measurement errors, stable structure, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

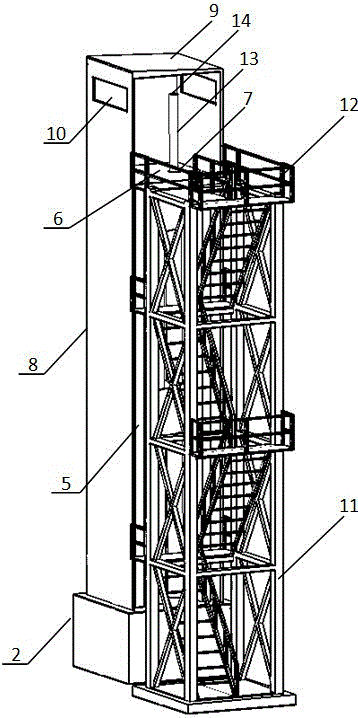

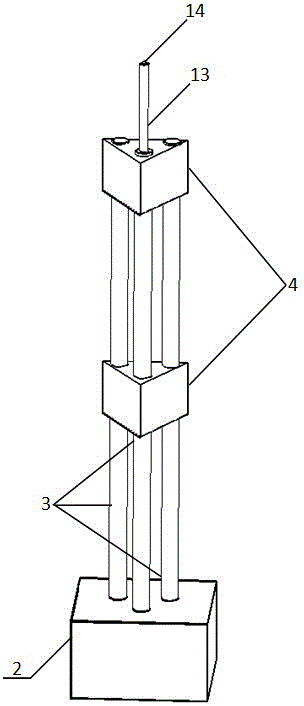

[0015] figure 1 and figure 2 A stable super-high observation tower for segmental beam prefabricated measurement is shown, including a steel pipe pile foundation buried underneath, a stable cap 2, a steel pipe column 3, a stable tie beam 4, a platform support 5, an observation platform 6, a protective Shed 8, combined safety ladder 11 and observation pier 13, the stable cap 2 is located on the ground, connected to the steel pipe pile foundation, the steel pipe column 3 is welded to the steel pipe pile foundation by three steel pipes, and passes through the stable cap 2. Concrete is poured inside, and the periphery is wrapped with double-layer geotextiles. The stable tie beam 4 is arranged in the middle and top of the steel pipe column 3, and is connected with three steel pipe columns 3 at the same time. Bearing the observation platform 6, the observat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com