Hydraulic quick discharge valve for monorail crane braking oil cylinder

A technology of brake oil cylinder and monorail crane, applied in the field of hydraulic valve, can solve the problems of long connecting oil pipe, long time to return to the oil tank, delay in braking of monorail crane, etc. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

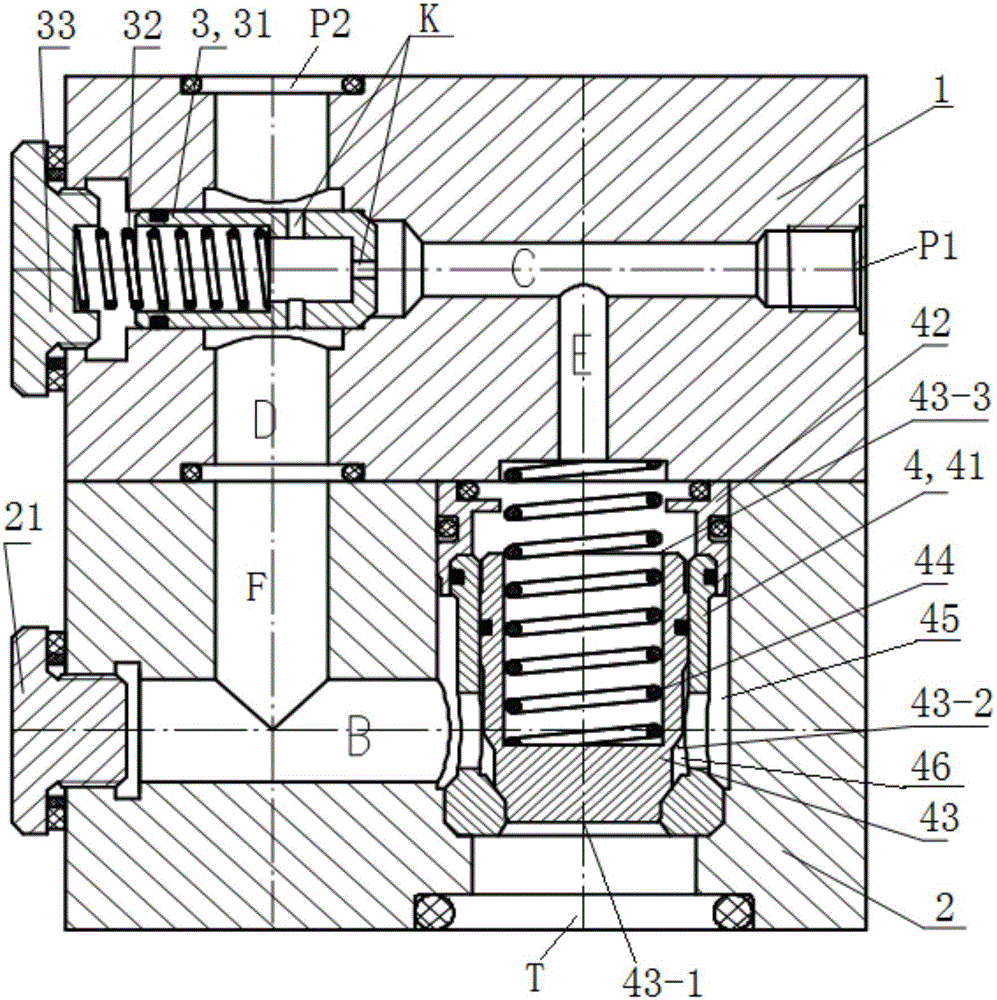

[0023] See figure 1 , The hydraulic quick discharge valve used for the monorail brake cylinder of the present embodiment mainly consists of an upper valve seat 1, a lower valve seat 2, a one-way throttle valve 3 and a plug valve 4.

[0024] The middle part of the right end of the upper valve seat 1 is provided with an oil inlet P1, and the oil inlet P1 is connected to the oil tank of the monorail crane through the oil pipe when in use; The brake cylinders of the suspension are connected to each other for the oil in and out of the brake cylinders; the upper valve seat 1 is provided with a left and right first flow channel C for hydraulic oil circulation, and the right end of the first flow channel C communicates with the oil inlet P1; the upper valve The left part of the seat 1 is provided with a one-way throttle valve installation hole that is the same as the axis line of the first flow channel C; the upper valve seat 1 is provided with a second flow channel D up and down for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com