Antiskid differential

A technology of anti-slip differentials and moving rings, which is applied in the direction of differential transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as complex meshing of internal structures, influence on use effects, and increased process requirements, and achieve ingenious design , Improve passing capacity, solve the effect of slipping and idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

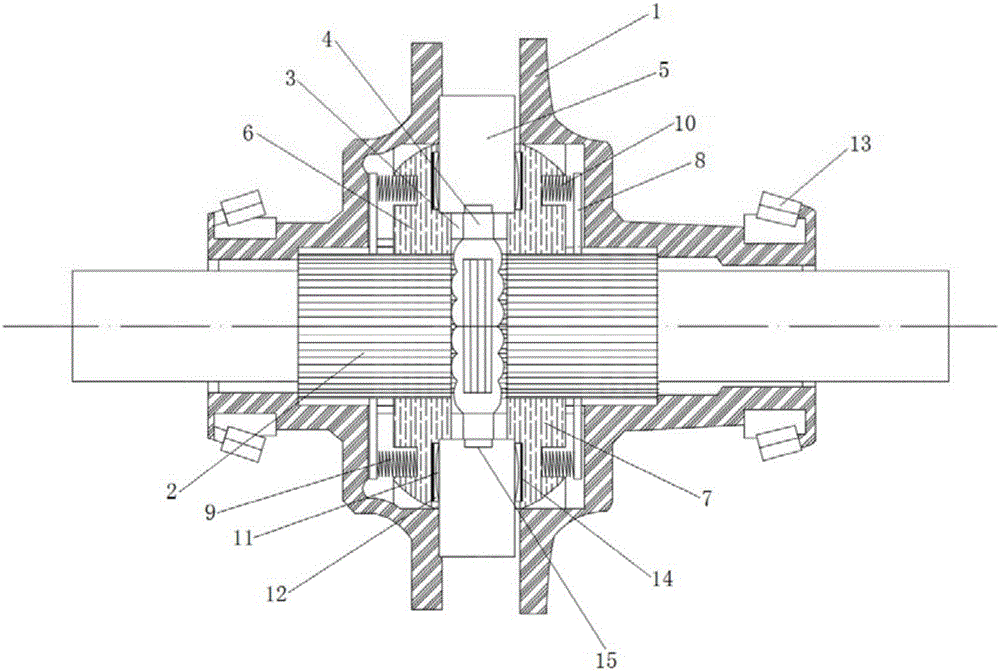

[0028] combine figure 1 As shown, a non-slip differential in this embodiment includes an outer shell 1, a half shaft spline hub 2, a center ring 4, a driving ring 5, a left driven ring 6, a right driven ring 7, a spring seat 8, The left auxiliary spring 9 and the right auxiliary spring 10, the outer shell 1 adopts a two-lobe structure, and is connected by bolts as an integral structure. The outer shell 1 also has a transmission mechanism connected with the output shaft of the engine. Two sets of half-shaft spline hubs 2 are used to externally connect the left and right wheel half-shafts. The left and right wheel half-shafts are splined to the corresponding half-shaft spline hubs 2, which is easy to install and has a large transmission torque; the two sets of half-shaft spline hubs The inner ends of 2 are each equipped with a snap ring 3, the center ring 4 is installed between the two snap rings 3, the center ring 4 is limited between the two snap rings 3 and cannot move axiall...

Embodiment 2

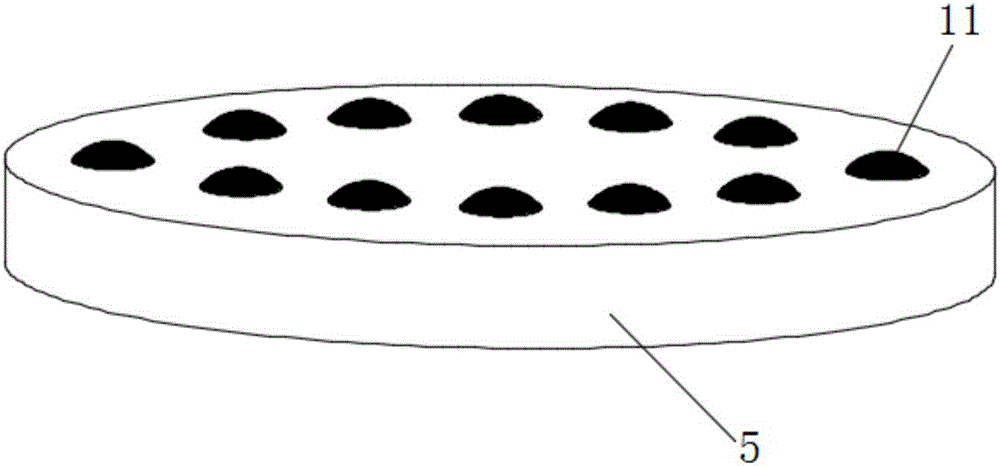

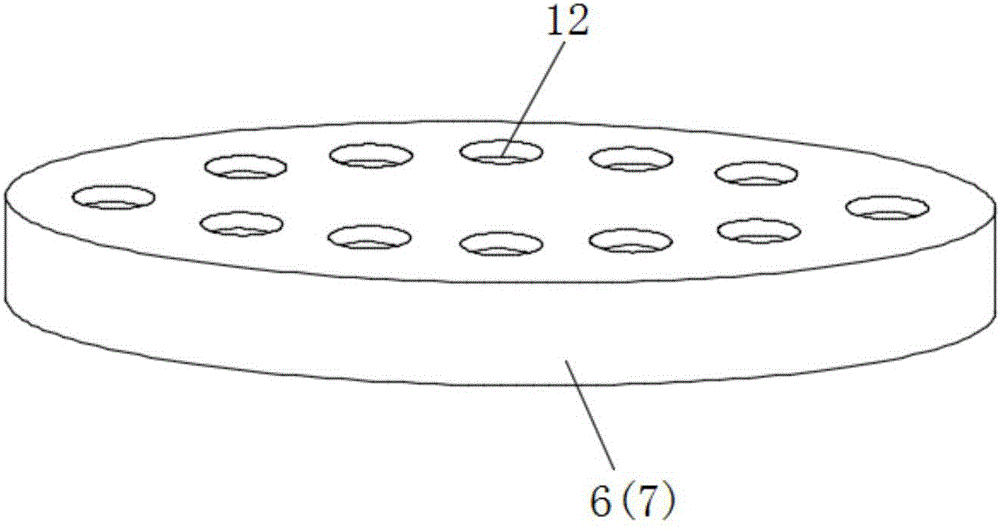

[0032] A non-slip differential of this embodiment has the same basic structure as that of Embodiment 1, except that in this embodiment, the locking teeth structure includes concave locking teeth 12 uniformly arranged on the outer wall of the driving ring 5, uniformly The convex locking teeth 11 located on the inner side walls of the left driven ring 6 and the right driven ring 7, the convex locking teeth 11 are protrusions of a spherical structure, and the concave locking teeth 12 are grooves of a cylindrical structure. The latch teeth 12 are meshed. The locking tooth structure can also play a role similar to that of the locking tooth structure in Embodiment 1.

[0033] In order to better understand the content of the present invention, now in conjunction with figure 1 Set forth the working principle of a kind of limited slip differential of above-mentioned embodiment 1 and embodiment 2:

[0034] When in use, the torque of the engine is transmitted to the outer casing 1, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com