Shell of driving roller

A technology for driving rollers and shells, applied in the direction of pipes/pipe joints/fittings, special pipes, mechanical equipment, etc., can solve the problems of high replacement costs, achieve the effects of increasing contact surface, preventing slipping and idling, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

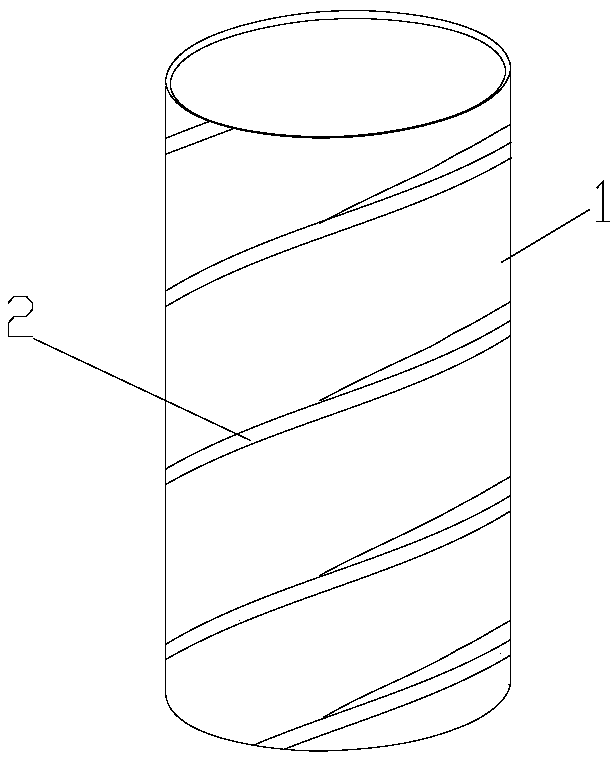

[0037] like figure 1 As shown, a shell 1 of a driving drum is shown. The shell 1 is cylindrical, and the outer peripheral surface of the shell is fixedly provided with a helical blade 2 along its length direction. The shell is integrally formed and straight. If the driving roller is a columnar body, it is very convenient to assemble. It only needs to cover the outer shell on the driving roller. The blades on the outer peripheral surface of the housing 1 are in a continuous spiral shape. The pitch of the helical blade is 5cm, the height of the helical blade is 3cm, and the width of the helical blade is 2cm.

Embodiment 2

[0039] In this embodiment, the shell is divided into two halves by a plane perpendicular to its axis, and is two straight cylinders. When assembling, the two half shells are respectively sleeved on the driving roller from the ends. The blades on the outer peripheral surface of the housing 1 are in a continuous spiral shape. In other embodiments, the shell is divided into two frustoconical shells by a plane perpendicular to its axis.

Embodiment 3

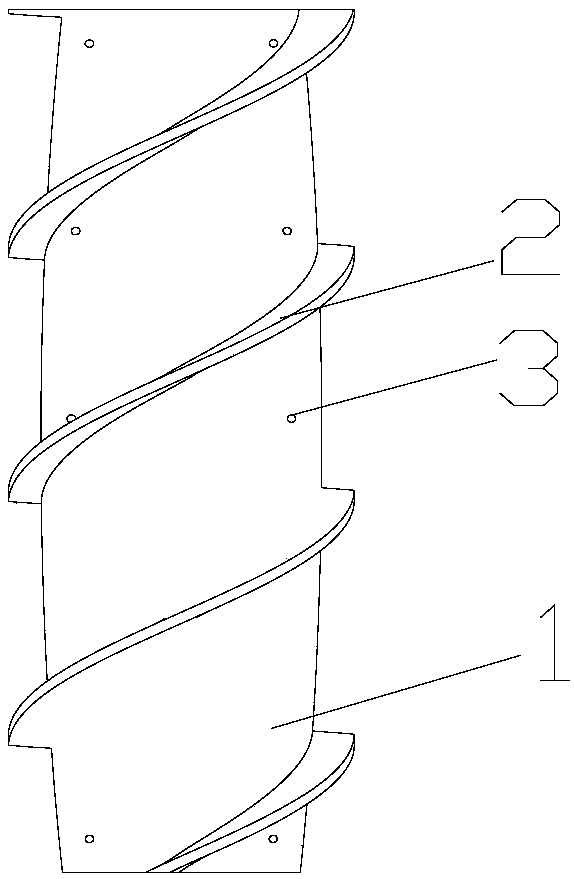

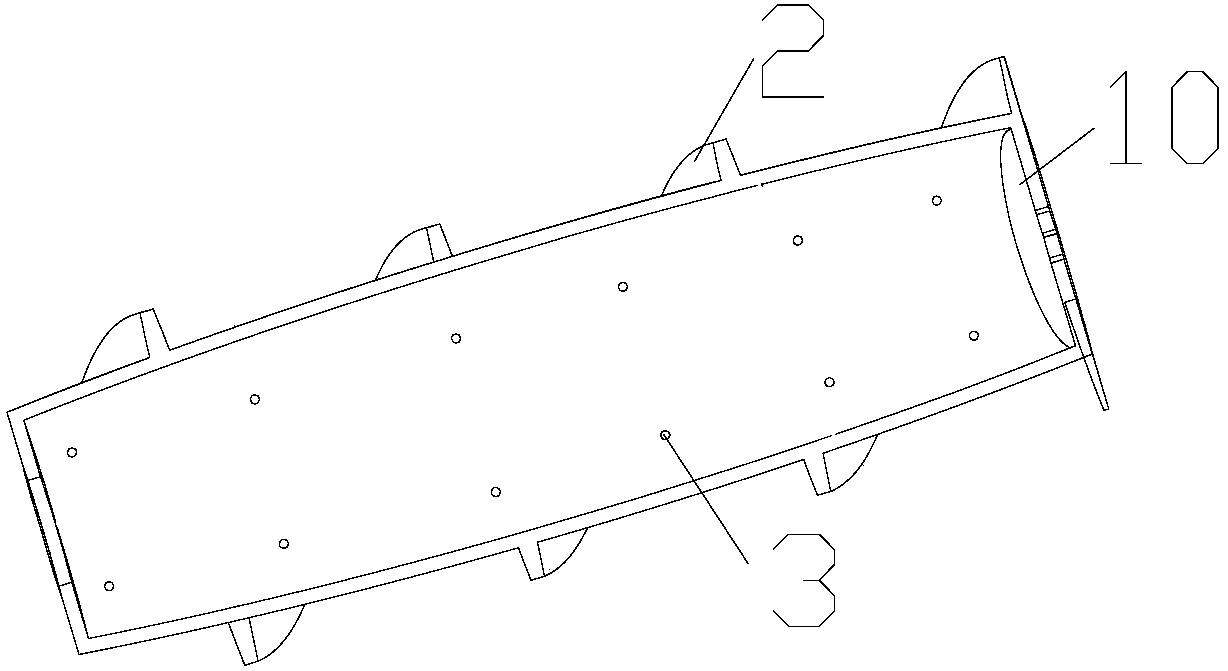

[0041] like figure 2 , 3 As shown, in this embodiment, the housing 1 is divided into two halves along the axial direction. The inner wall of the housing is a smooth arc surface, and the housing is provided with threaded holes 3 for fixing the housing and the driving drum, and the housing and the driving drum are fixed by screws, which is convenient for disassembly. The blades on the outer peripheral surface of the housing 1 are in a continuous spiral shape. The pitch of the helical blade 2 is 8cm, the height of the helical blade 2 is 3cm, and the width of the helical blade 2 is 2cm.

[0042] Both ends of the housing are provided with head plates 10 to prevent water or dirt from entering the gap between the housing and the driving drum.

[0043] The shell 1 is in the shape of a tapered shuttle and includes three sections: a straight barrel section in the middle and a frustum shell section at both ends, and the three sections are integrally formed. Tapered shuttle-shaped de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com