limited slip differential

A technology of anti-skid differentials and gears, which is applied in the direction of differential transmissions, belts/chains/gears, mechanical equipment, etc. It can solve problems such as easy wear of mechanisms, increased process requirements, and failure of driving power to solve slippage The effect of idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

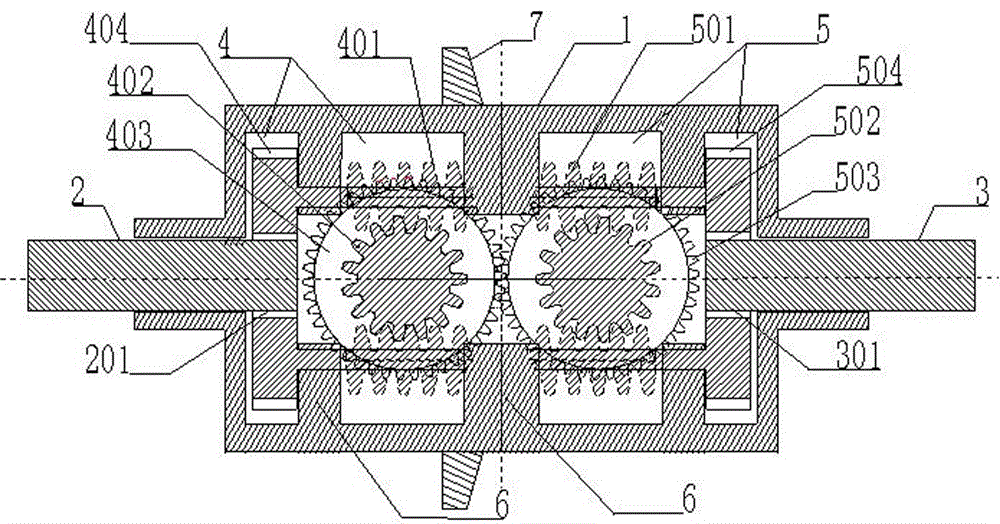

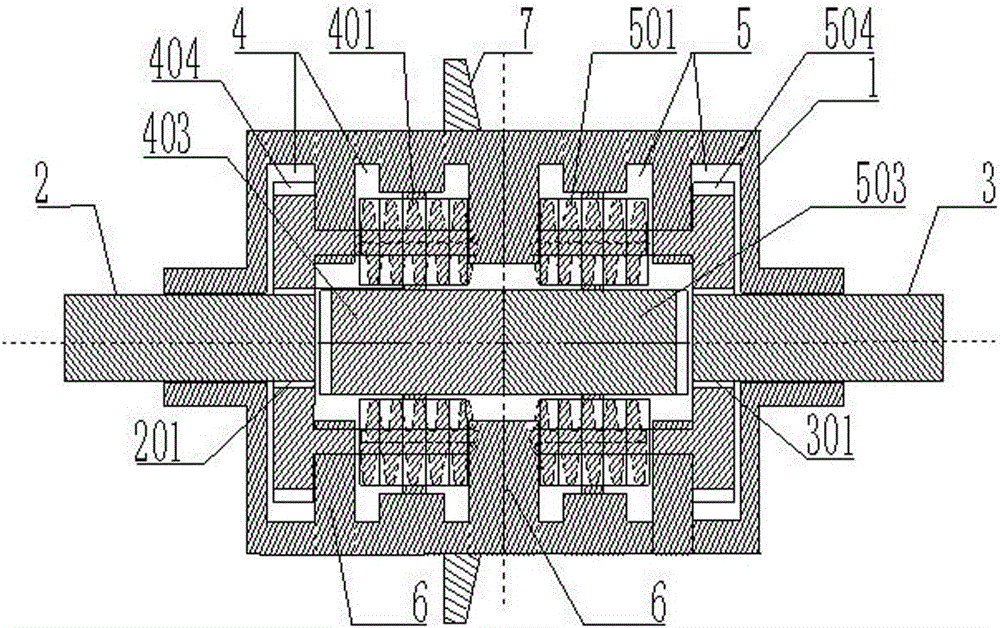

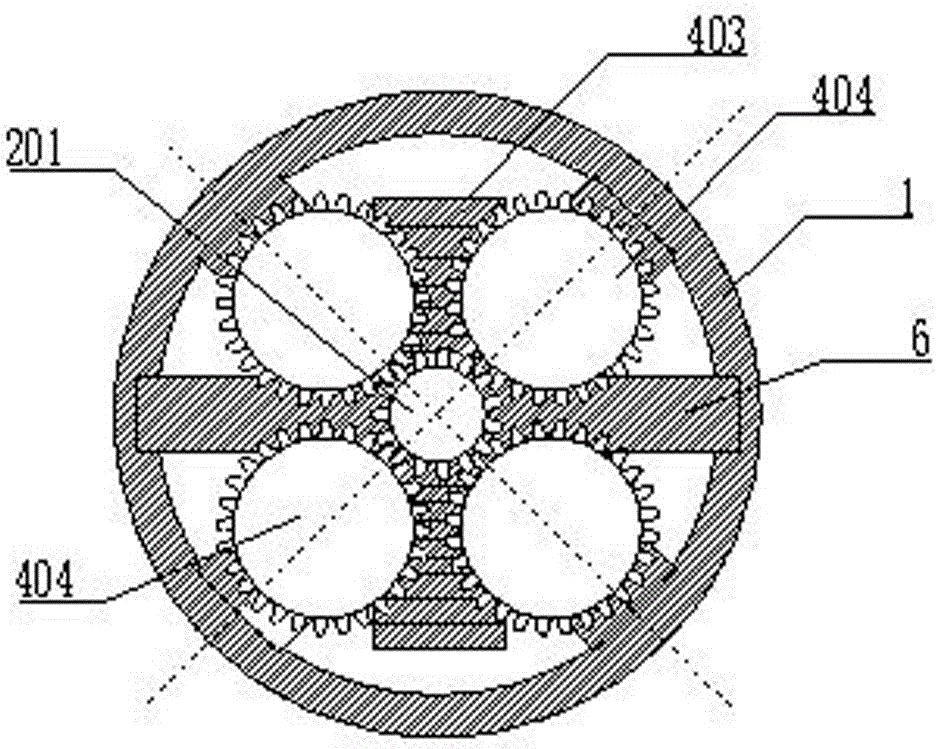

[0021] see figure 1 , figure 2 , image 3 Shown: a non-slip differential, including a housing 1, a left output half shaft 2 and a right output half shaft 3.

[0022] Wherein, the housing 1 has at least two relatively independent cavities inside. The cavity on the left side is used for assembling the left conversion part 4 , and the cavity on the right side is used for assembling the right conversion part 5 . The left output shaft 2 is assembled on the left end of the housing 1, and is connected with the left conversion part 4 assembled in the housing 1, and the right output shaft 3 is assembled at the right end of the housing 1, and is connected with the right conversion part assembled in the housing 1. Section 5 is connected.

[0023] The left conversion part 4 is mainly composed of two groups, each group of two first worms 401 (at least one group, each group is one first worm 401, but in order to ensure the stability of the transmission, generally two symmetrical groups...

Embodiment 2

[0032] The other structure of this embodiment is the same as that of Embodiment 1, the difference is that the housing of the invention is not divided into two cavities, left and right, but a housing composed of one cavity, in which there are left and right cavities. Two conversion parts.

Embodiment 3

[0034]The other structure of this embodiment is the same as that of Embodiment 2 and Embodiment 3, the difference being that the left conversion part is a group of worms and a worm wheel in the left and right conversion parts of the invention, and the right conversion part is two groups of worms and two An asymmetric arrangement consisting of two worm gears, wherein each group of worm gears is one, depending on the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com