Belt tensioning assembly

A belt and component technology, applied in the field of belt tensioning components, can solve the problems of long belt tensioning distance and achieve the effects of stable operation, preventing movement and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

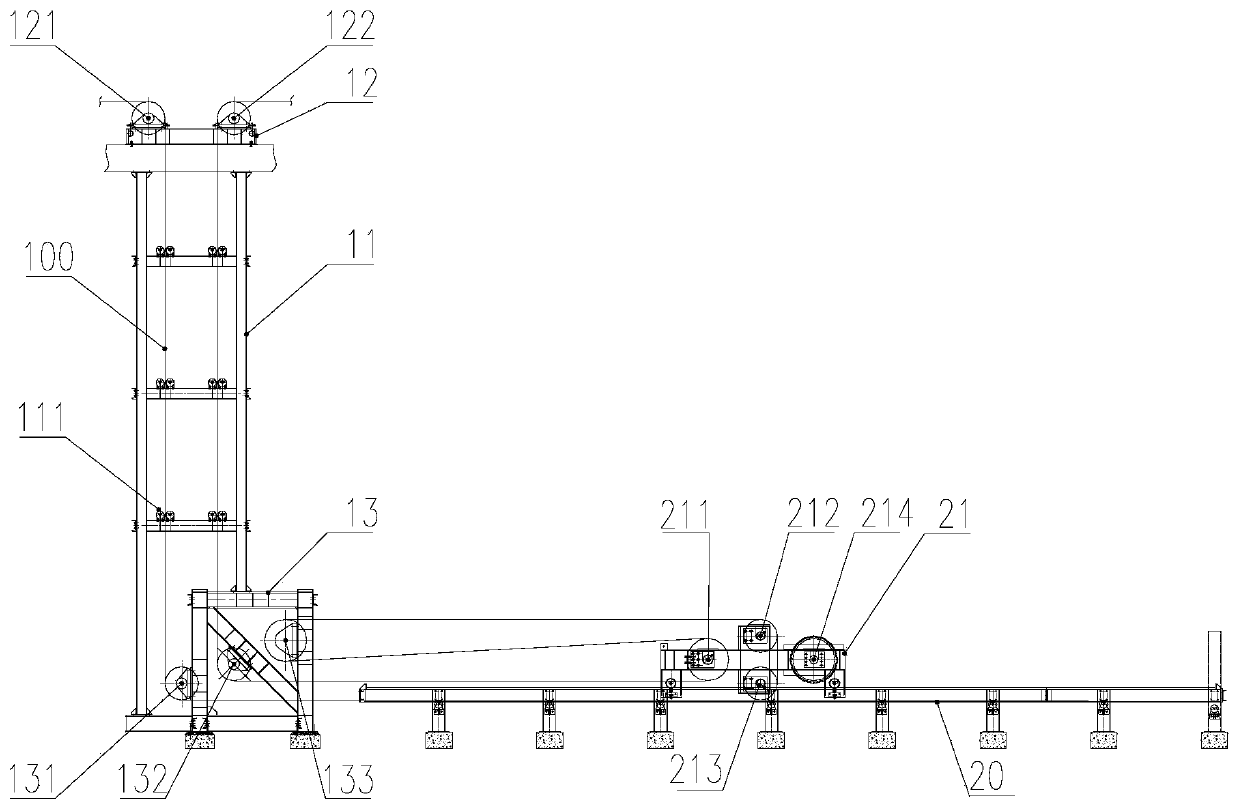

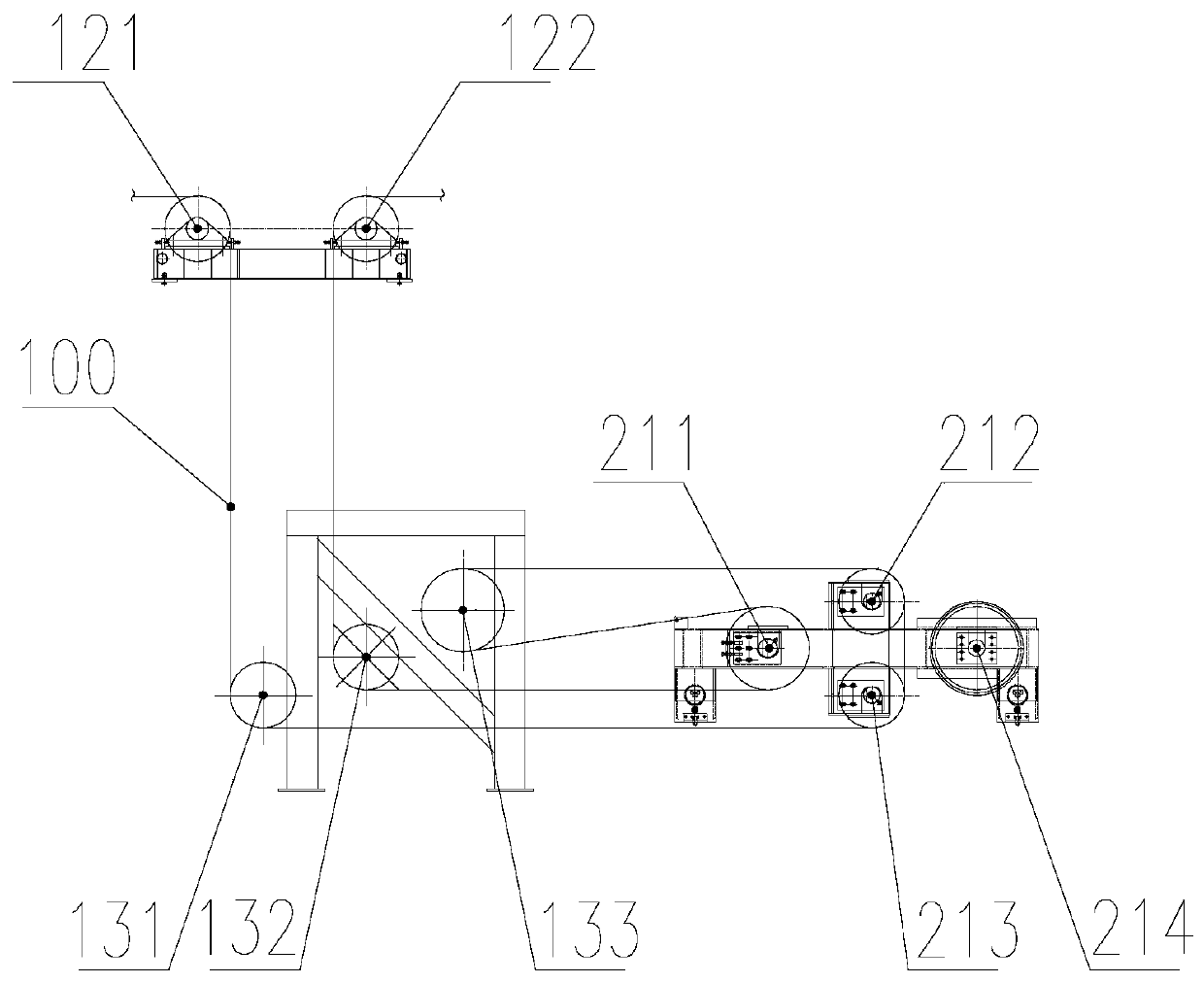

[0055] combine figure 1 , figure 2 As shown, the present invention provides a belt tensioning assembly, comprising:

[0056] Belt 100, the belt 100 is a continuous belt connected end to end;

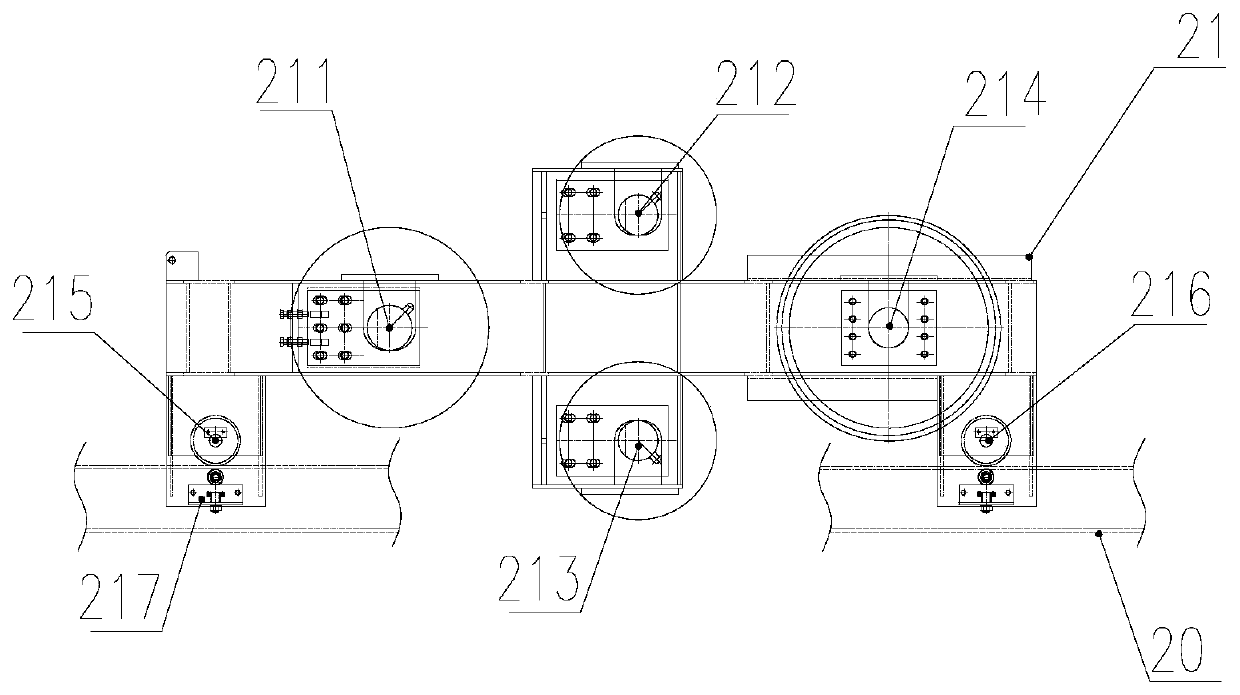

[0057] Tensioning mobile platform 21, the first end of which is provided with at least one tensioning mobile platform roller, said tensioning mobile platform roller is suitable for winding the belt 100;

[0058] Combination turning roller seat 13, which includes at least one transfer turning roller, which is suitable for turning the belt 100 conveyed by belt tower 11; and at least one incremental turning roller, which The incremental redirecting roller is suitable for cooperating with the tensioning mobile platform roller to increase the number of winding segments of the belt 100 on at least one tensioning mobile platform roller of the tensioning mobile platform 21 .

[0059] The present invention provides a belt tensioning assembly. By cooperating and winding the belt 100 delivered ...

Embodiment 2

[0079] combine Figure 6 , Figure 7 As shown, the present invention also provides an adaptive tensioning system for a belt conveyor, which includes the belt tensioning assembly as described in Embodiment 1, which also includes:

[0080] Weight box 32, the weight box 32 is suitable for pulling the steel wire rope 200 through the pulley block, so that the steel wire rope 200 pulls the tensioning mobile platform pulley 214 and drives the tensioning mobile platform 21 sports;

[0081] The weight box 32 is slidingly matched with the steel wire rope 200 in the X section, and the tensioning mobile platform pulley 214 is slidingly matched with the steel wire rope 200 in the Y section, so that the tensioning mobile platform roller pulls the belt 100 in the Z section Move, where, X≥2, Y≥1, Z≥2.

[0082]It is worth noting that in the above-mentioned "sliding fit between the weight box 32 and the steel wire rope 200 in the X section", the "X section" does not refer to X steel wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com