A high-efficiency variable-direction diamond wire saw machine for nuclear facility dismantling

A diamond wire saw machine and a technology for nuclear facilities, applied in the field of nuclear engineering, can solve the problems of independent high-altitude operation, changing cutting directions multiple times, radiation damage to operators, and bulky containment, so as to ensure accuracy and improve engineering efficiency. , the effect of rich feed margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

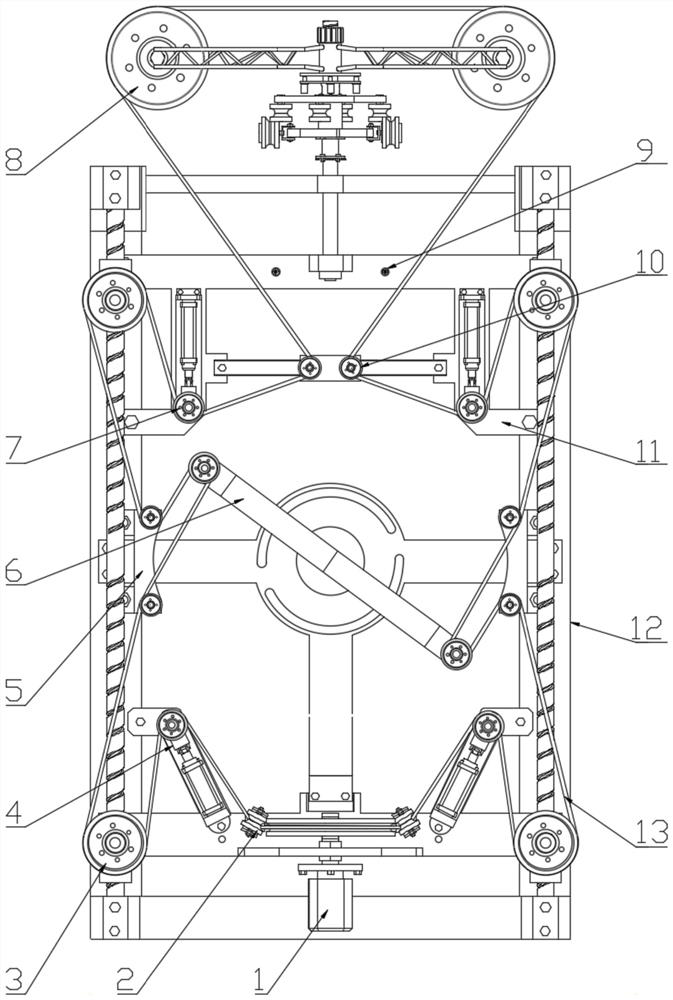

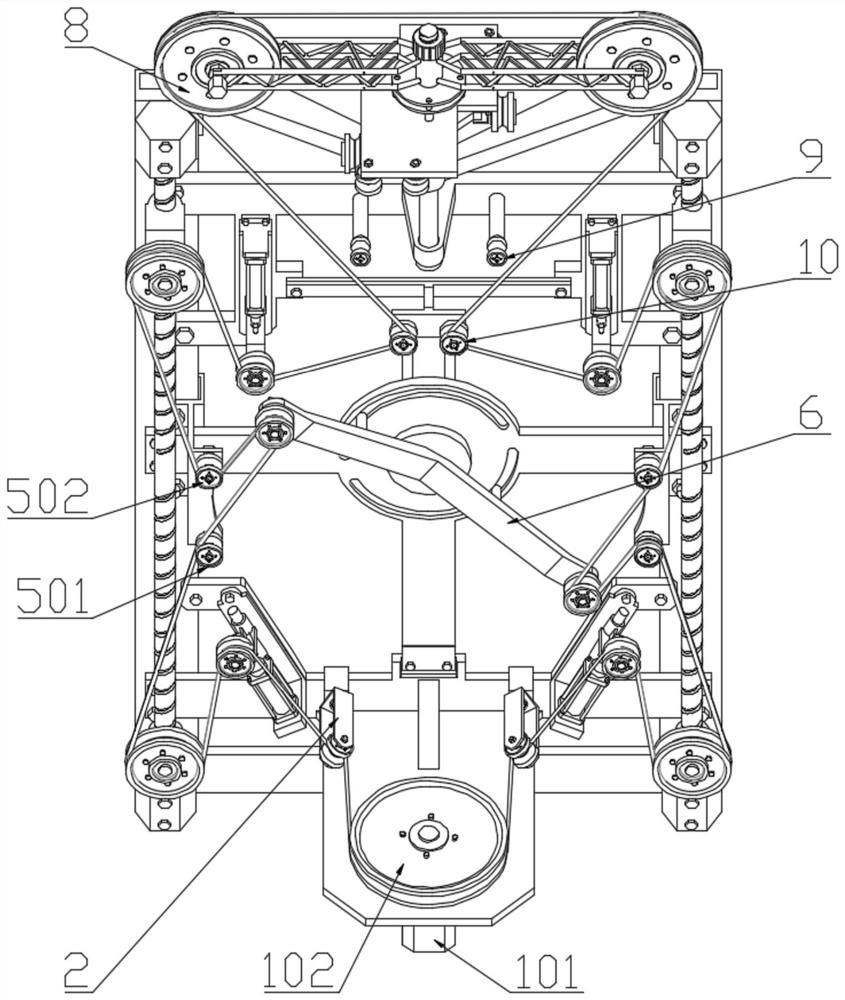

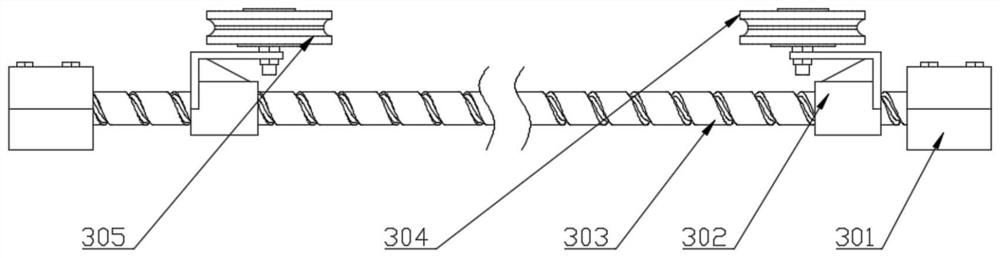

[0025] Such as figure 1 , image 3 , Figure 4 , Figure 6 , Figure 7 , Figure 9 as well as Figure 10 As shown, it mainly consists of cutting mechanism 1, reverse screw screw feeding mechanism 3, auxiliary wheel train structure 2, hydraulic tensioning structure 4, V-shaped frame rotatable feeding mechanism 6, auxiliary hydraulic tensioning structure 7 and direction changing The organization consists of 8. Each part is installed on the base 12 in turn. The power motor 101 on the cutting mechanism drives the cutting wheel 102 to rotate, and the cutting wheel 102 transmits power to the diamond beaded rope 13 thereon. The beaded rope 13 reaches the reverse screw screw feeding mechanism 3 via the auxiliary wheel train structure 2 and the hydraulic tensioning mechanism 4 . The auxiliary wheel 203 on the auxiliary wheel train mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com