A design method for deflectable sawtooth wing leading edge

A technology of wing leading edge and design method, which is applied in design optimization/simulation, aircraft parts, geometric CAD, etc., can solve the problems of pitching moment up-up phenomenon, wing outer wing stall, sudden head-up moment, etc., to ensure the curved surface The effect of mass, simple motion form, and simple drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

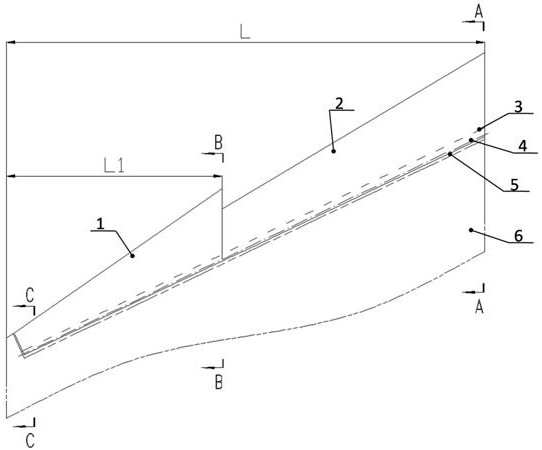

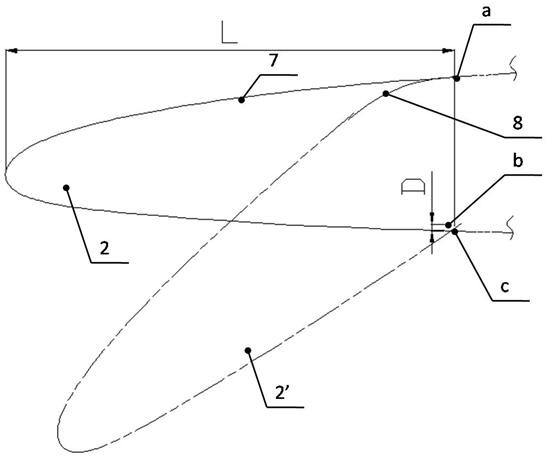

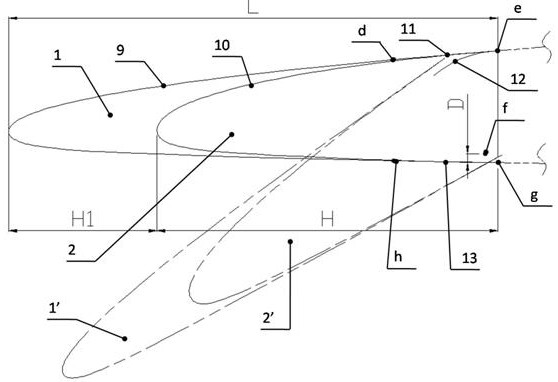

[0022] see Figure 1~4 A deflectable sawtooth wing leading edge design method, the deflectable sawtooth wing leading edge includes a serrated segment leading edge 1, a deflected serrated segment leading edge 1', an inner segment leading edge 2, and a deflected inner segment leading edge 2' , sealing plate 3, deflection shaft 4, leading edge rear boundary 5, fixed airfoil 6, the specific design steps are as follows:

[0023] 1) Determine the size parameter L of the leading edge of the airfoil curve as 3000-4000mm and the starting position L1 of the sawtooth section as 1200-1800mm. According to the design goal of the sawtooth to inhibit the flow of the boundary layer to the wingtip, generally take L1 / L to be approximately equal to 40% , in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com