A fault-tolerant control system and control method for automotive brake-by-wire failures

A fault-tolerant control, brake-by-wire technology, applied in the direction of brake control systems, brakes, brake components, etc., to achieve the effect of coordinated control and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

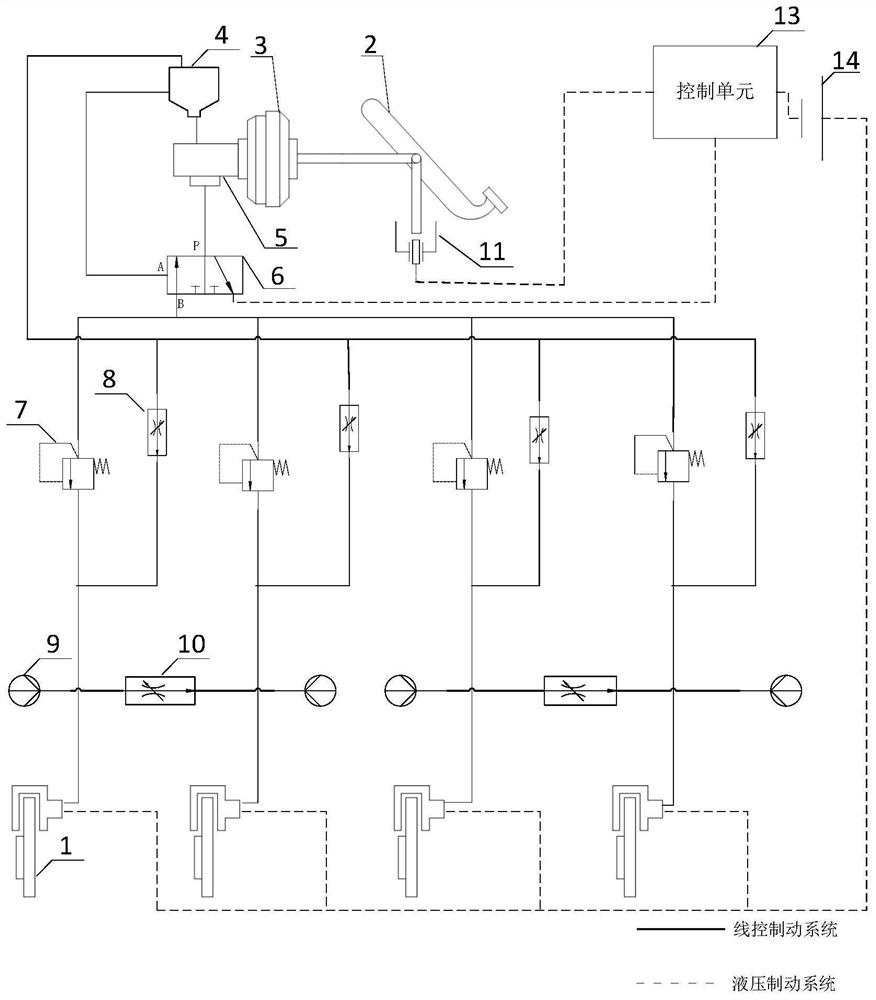

[0033] Such as figure 2 As shown, the present invention is a schematic structural diagram of a fault-tolerant control system for automobile brake-by-wire failures, including a brake 1, a brake pedal 2, a vacuum booster 3, a liquid storage tank 4, a brake master cylinder 5, a two-position three Solenoid valve 6 , boost valve 7 , control valve 8 , wheel cylinder sensor 9 , balance valve 10 , pedal angle sensor 11 , control unit 13 and battery 14 .

[0034] The vacuum booster 3 is connected between the brake pedal 2 and the brake master cylinder 5, and the liquid storage tank 4 is connected to the brake master cylinder 5; the brake pedal 2 is used for braking or releasing the brake when the vehicle needs to brake , to give the driver a certain feeling; the vacuum booster 3 is used to provide assistance for the driver’s operation of the brake pedal 2, and in the hydraulic brake system, the force of the driver stepping on the brake pedal 2 is amplified and transmitted to The brak...

Embodiment 2

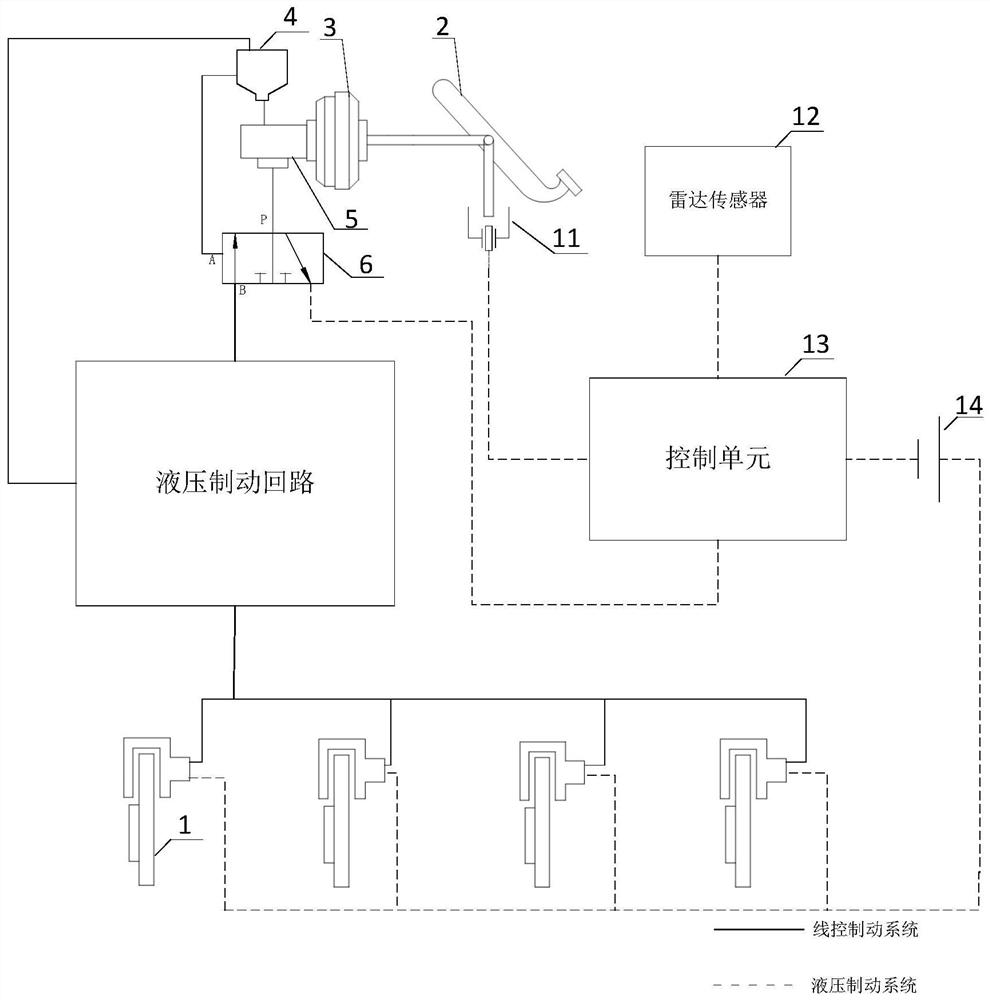

[0047] Such as Figure 8 As shown, the present invention is a structural schematic diagram of a fault-tolerant control system for automotive brake-by-wire failures, including the fault-tolerant control system as described in Embodiment 1, and its structure, working principle and working process have been described in Embodiment 1 , will not be described in detail here; the fault-tolerant control system in this embodiment also includes a radar sensor 12 connected with the control unit 13 signal, and the radar sensor 12 is installed on the self-driving car to sense the surrounding road conditions and judge whether it is necessary to control the vehicle. move.

[0048] The control method of the fault-tolerant control system in this embodiment includes the following steps:

[0049] Step 1, the radar sensor 12 judges whether braking is required according to the road surface information in front of the vehicle;

[0050] Step 2, when the brake-by-wire system is normal, the radar se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com