Novel sealing mechanism

A sealing mechanism and a new type of technology, applied in the direction of mechanical equipment, threaded connections, pipes/pipe joints/fittings, etc., can solve the problems of harsh processing requirements, waste of resources, high cost, etc., and achieve good sealing performance, reasonable structure, and low requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

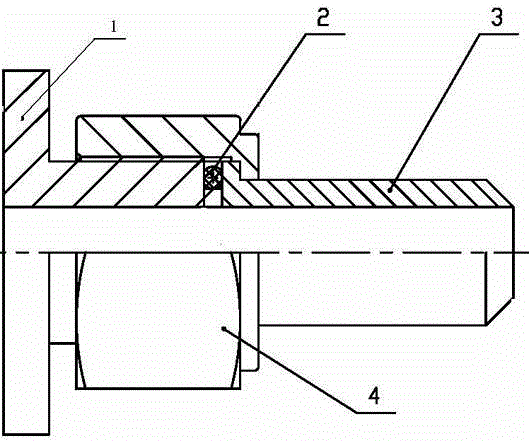

[0013] Referring to the accompanying drawings, the present invention includes a wire base 1, a tube base 3 and a nut 4, the wire base 1 and the tube base 3 are fixed together by the nut 4, and a groove is arranged on the head of the wire base 1, A sealing ring 2 is arranged in the groove. The sealing ring 2 is made of elastic material. The working principle is:

[0014] As shown in the accompanying drawings, the wire seat in the figure can be the wire seat in the three-head pipe joint, or straight through, as long as the structure of the wire seat is guaranteed, the nut 4 cooperates with the wire seat 1, and the pipe seat 3 passes through The nut 4 is fixed with the wire base 1, and the sealing ring 2 is placed in the groove of the head of the wire base 1 in the figure, and the sealing ring can be placed in the outer diameter groove of the wire base 1 in some applications. The sealing principle is to use the pre-tightening force of the nut 4 in the working process to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com