Mechanical part hole inner ring groove width dimension quantitative measurement device

A technology of groove width and mechanical parts, which is applied in the field of quantitative measurement devices for the width and dimension of inner ring grooves of mechanical parts, and achieves the effects of convenient measurement, easy manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

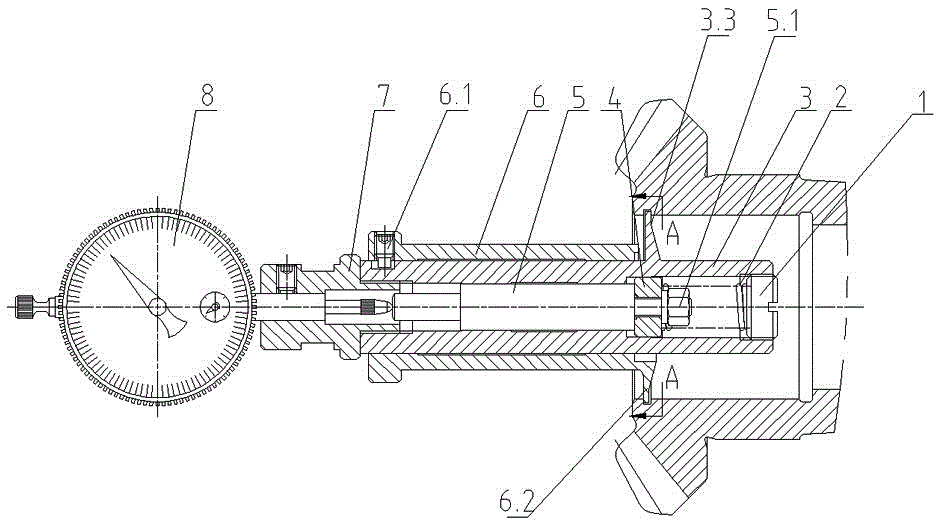

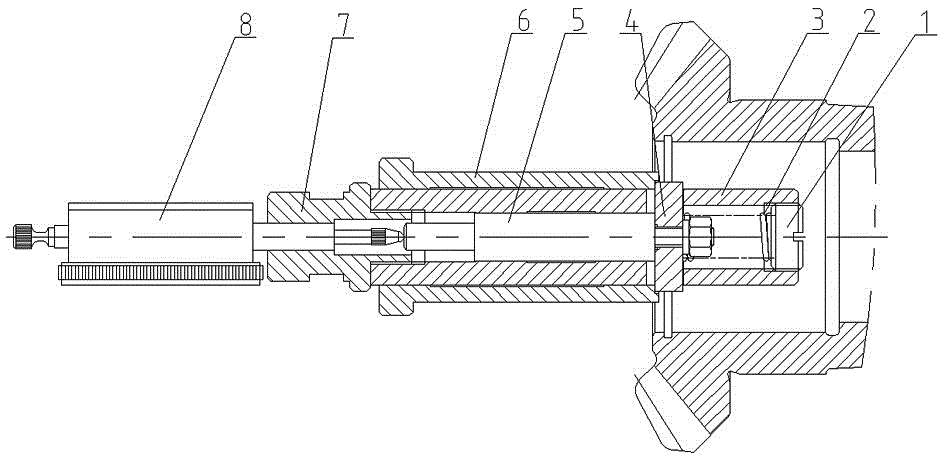

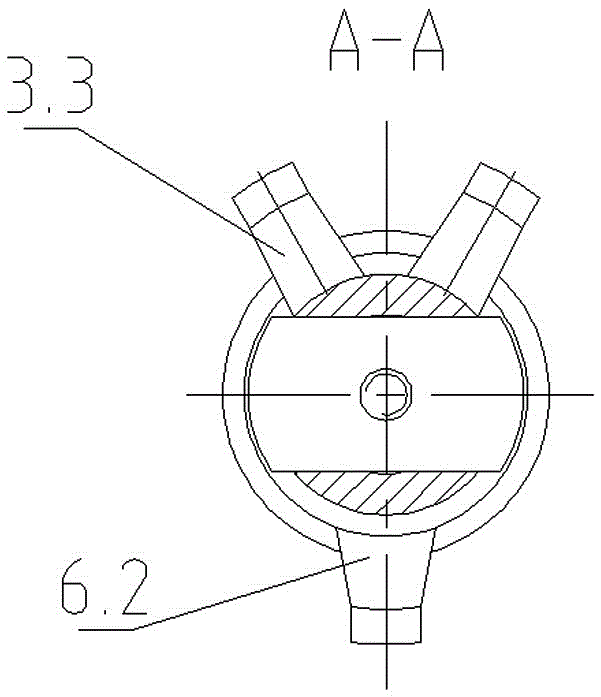

[0020] figure 1 and figure 2 The shown quantitative measuring device for the groove width of the inner ring groove of a mechanical part includes a screw plug 1, a spring 2, an inner tube 3, a slider 4, a measuring rod 5, an outer tube 6, a gauge base 7 and a dial gauge 8. The head end of the dial gauge 8 is inserted into the inner hole of the watch base 7 , and the threaded end of the sleeve-like watch base 7 is connected to the inner pipe 3 . Inner pipe 3 among the present invention is as Figure 4 As shown, it is a straight tubular member, and an end outer wall connected with the table seat 7 is provided with a section such as Figure 5 The annular radial groove 3.1 shown in this embodiment is used to measure the side gear in the car differential. Because the workpiece aperture size is relatively small, the radial groove 3.1 is 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com