Compound pressure and vacuum gage for displaying different measuring ranges by linear scales

A technology of pressure vacuum gauge and linear scale, applied in the direction of measuring fluid pressure, vacuum gauge, measuring device, etc., can solve the problem of inaccurate measurement, and achieve the effect of simple device and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

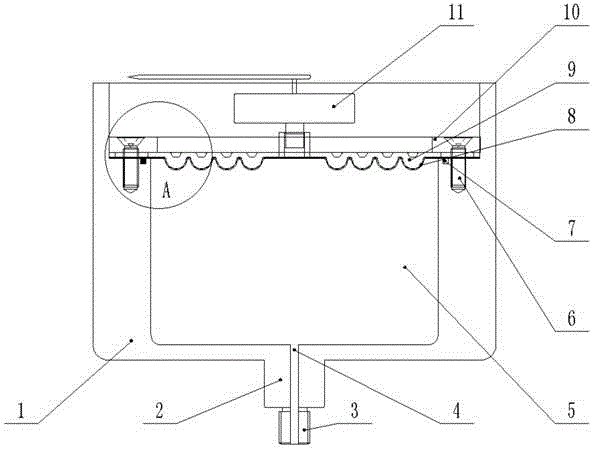

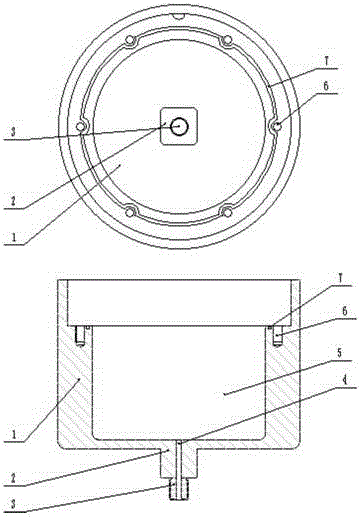

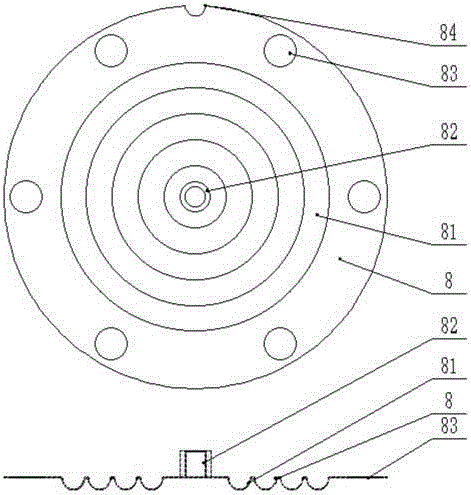

[0029] Such as Figure 1-7 As shown, a pressure vacuum gauge with a linear scale displaying different ranges in the embodiment of the present invention includes: the pressure gauge plate 1 is a hollow cylinder, the bottom of the pressure gauge plate 1 is connected to the joint 3 through the flange 2, and the inside of the joint 3 is processed air Channel 4, there is a sinking shoulder on the inner side of the pressure dial 1, and the bolt hole 6 and the sealing groove 7 are processed at the sinking shoulder. The sealing groove 7 is a special-shaped structure, and there is a semicircular inner transition at the position of the bolt hole 6. The sealing ring and the sinking shoulder are also processed with a positioning protrusion; the vacuum deformation plate 8 is in the shape of a circular sheet, and a sleeve 82 is fixedly installed in the middle position, and a pointer mechanism 11 is connected above the sleeve 82, and the pointer mechanism 11 can move the vacuum deformation pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com