Air tightness detection method and mobile terminal

An airtightness detection and mobile terminal technology, which is applied in the electronic field, can solve the problems of low terminal airtightness detection efficiency and high detection cost, and achieve the effect of solving low detection efficiency and high detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

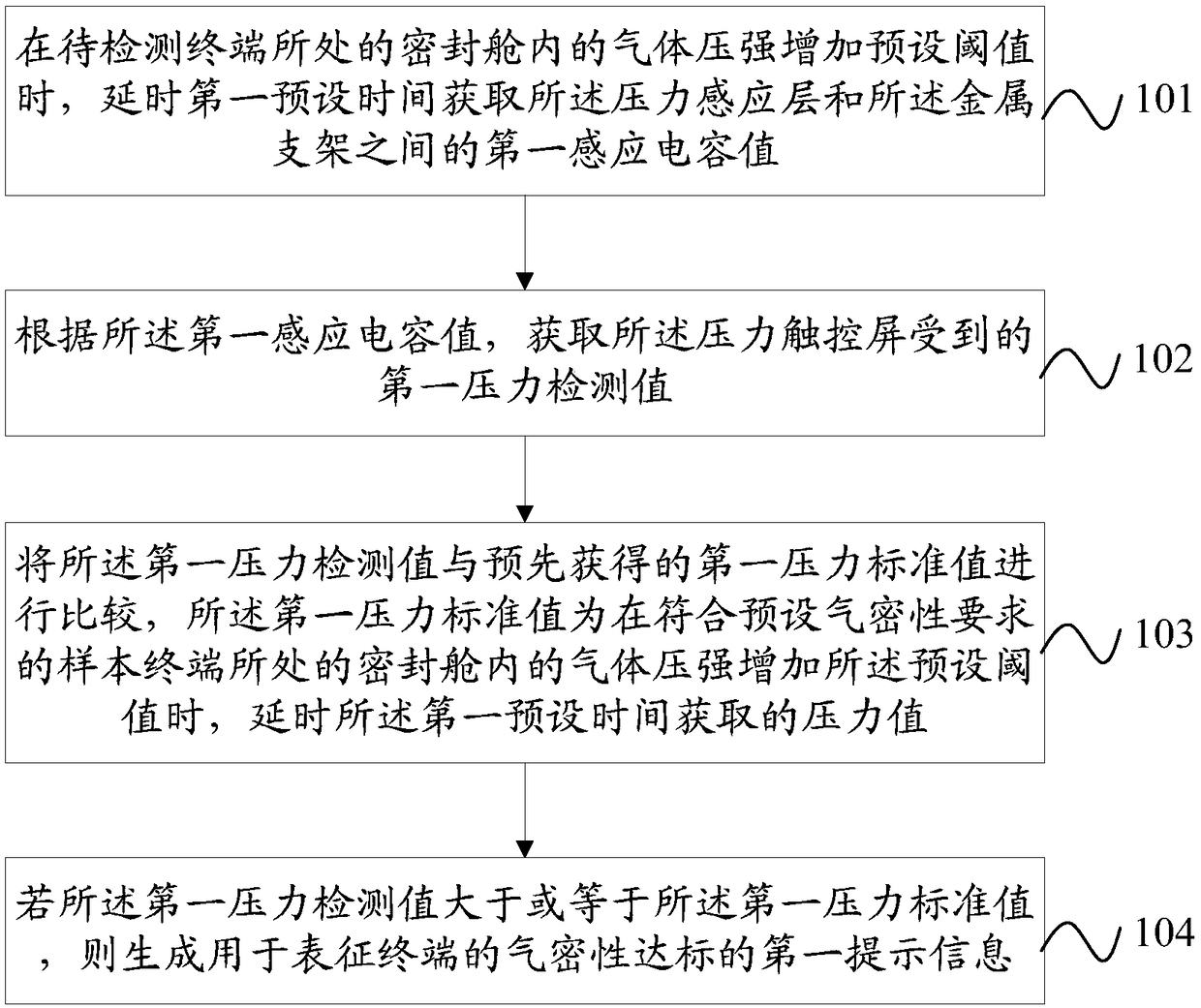

[0027] refer to figure 1 As shown, the air tightness detection method of the embodiment of the present invention includes:

[0028] Step 101, when the gas pressure in the airtight chamber where the terminal to be detected is located increases to a preset threshold, delaying for a first preset time to obtain a first sensing capacitance value between the pressure sensing layer and the metal bracket.

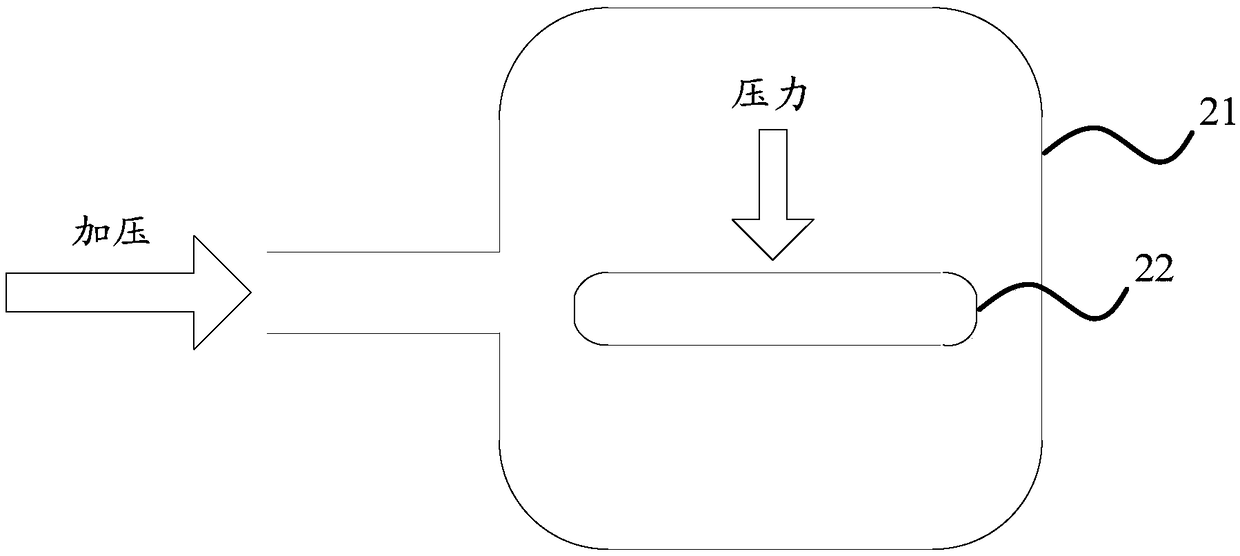

[0029] The method in the embodiment of the present invention is applied to a terminal with a pressure touch screen, and the terminal further includes a pressure sensing layer and a metal bracket sequentially disposed under the pressure touch screen. Specifically, in addition to the pressure touch screen, the terminal also includes an LCM (LCD Modul, liquid crystal display module), a pressure sensing layer, a metal bracket, a battery, and a rear cover arranged sequentially below the pressure touch screen, wherein There is a gap between the pressure sensing layer and the metal suppo...

no. 2 example

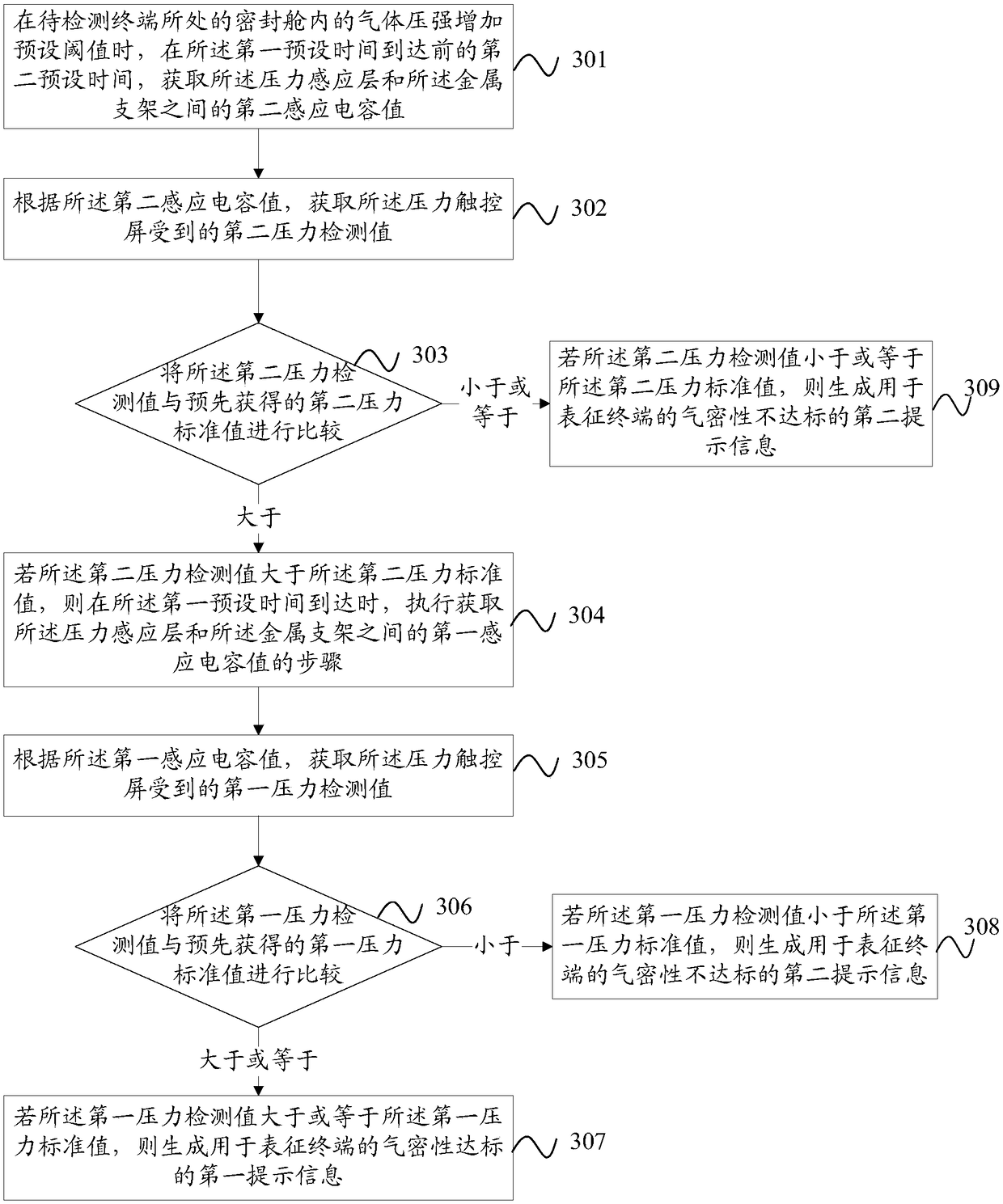

[0048] refer to image 3 As shown, the air tightness detection method of the embodiment of the present invention includes:

[0049] Step 301, when the gas pressure in the airtight cabin where the terminal to be detected is located increases to a preset threshold, acquire the pressure sensing layer and the metal bracket at a second preset time before the first preset time arrives. between the second sense capacitance value.

[0050] The method in the embodiment of the present invention is applied to a terminal with a pressure touch screen, and the terminal further includes a pressure sensing layer and a metal bracket sequentially disposed under the pressure touch screen. Specifically, in addition to the pressure touch screen, the terminal also includes an LCM (LCD Modul, liquid crystal display module), a pressure sensing layer, a metal bracket, a battery, and a rear cover arranged sequentially below the pressure touch screen, wherein There is a gap between the pressure sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com