Method for detecting air tightness of single crystal furnace

A detection method and technology of single crystal furnace, which are applied in single crystal growth, liquid tightness measurement using liquid/vacuum degree, chemical instruments and methods, etc., can solve the problems of poor air tightness and low pressure of single crystal furnace, and achieve The effect of improving production efficiency, reducing production cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

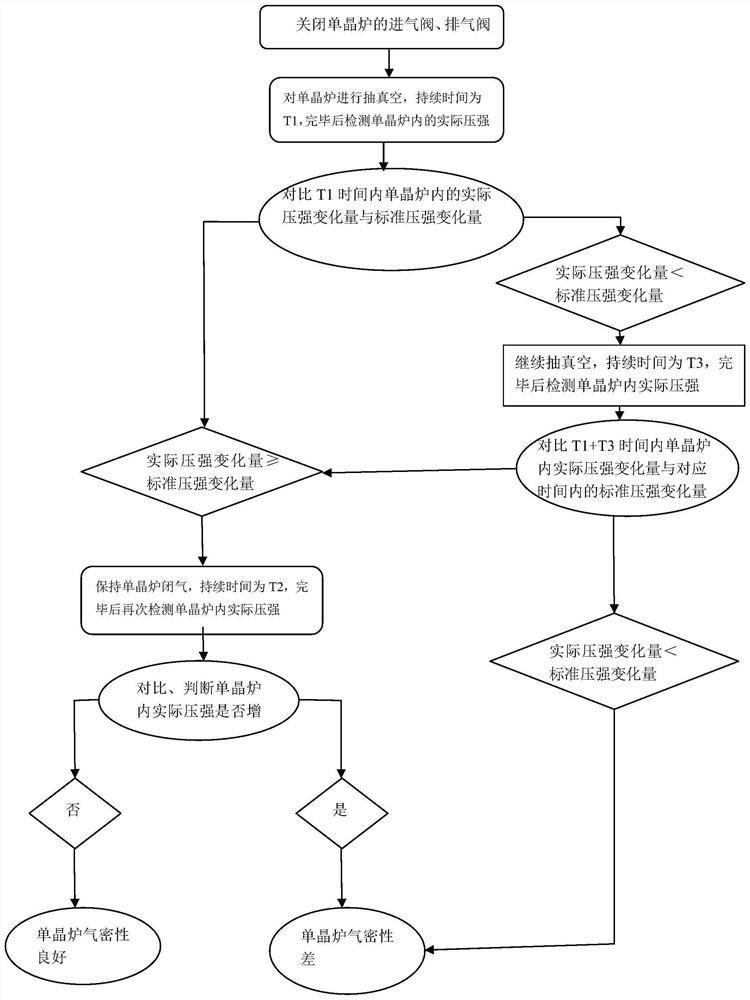

[0029] The method for detecting the airtightness of a single crystal furnace of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] like figure 1 As shown, the detection method of the airtightness of single crystal furnace of the present invention comprises:

[0031] S1. Close the intake valve and exhaust valve of the single crystal furnace;

[0032] S2. Vacuumize the single crystal furnace for a duration of T1, and detect the actual pressure in the single crystal furnace after completion;

[0033] S3. Comparing the actual pressure change in the single crystal furnace with the standard pressure change, if the actual pressure change in the single crystal furnace ≥ the standard pressure change, then directly execute step S4;

[0034] S4. Keep the single crystal furnace closed, and the duration is T2, and then detect the actual pressure in the single crystal furnace again after completion;

[0035] S5. Comparing and jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com