Forming gluing device for amorphous alloy stereoscopic wound iron core

A three-dimensional wound core and gluing device technology, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic core manufacturing, electrical components, etc., can solve the problems of the performance deterioration of the amorphous three-dimensional wound core and the fragility of the core, so as to reduce the impact, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

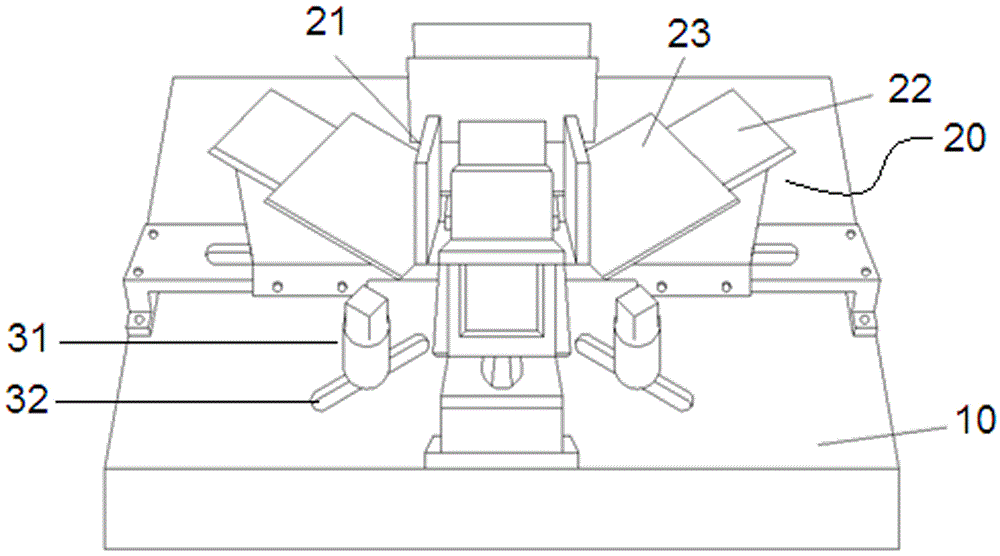

[0021] Such as figure 1 Shown is a forming glue coating device for an amorphous alloy three-dimensional wound core provided by the present invention, which includes:

[0022] base 10; and

[0023] Several sets of support assemblies 20 are arranged on the base 10, the support assemblies 20 include: a baffle 21 arranged perpendicular to the base, a bottom plate 22 arranged at an angle to the base 10, and a bottom plate 22 parallel to the bottom plate 22 and movably arranged on the bottom plate 22 Backing plate 23, this backing plate 23 can be drawn out according to need;

[0024] Wherein, the baffle 21 is adjacent to the end of the bottom plate 22 (the ends of the two can be flexibly connected or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com