Inverted LED car lamp

A technology of LED car lights and LED chips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of large car light assembly, complex overall structure of lamps, and inconvenient vehicle shape design, so as to achieve concentrated light and facilitate vehicle Shape design, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

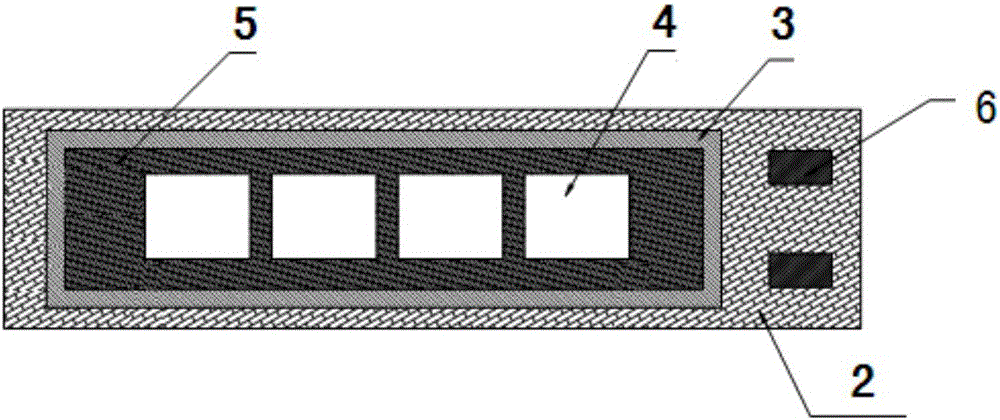

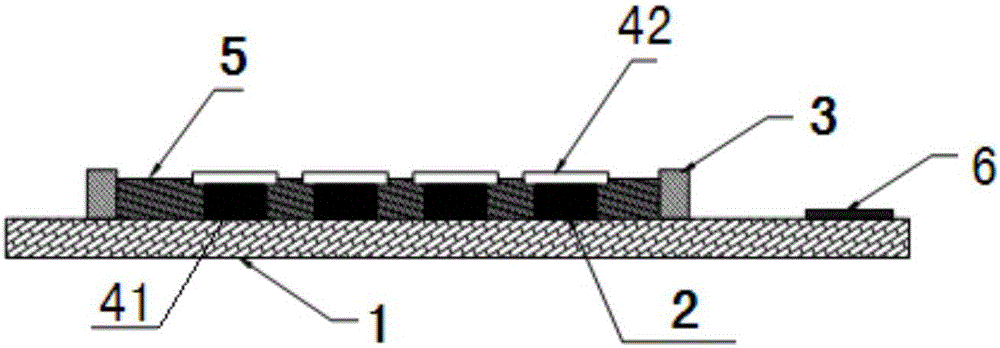

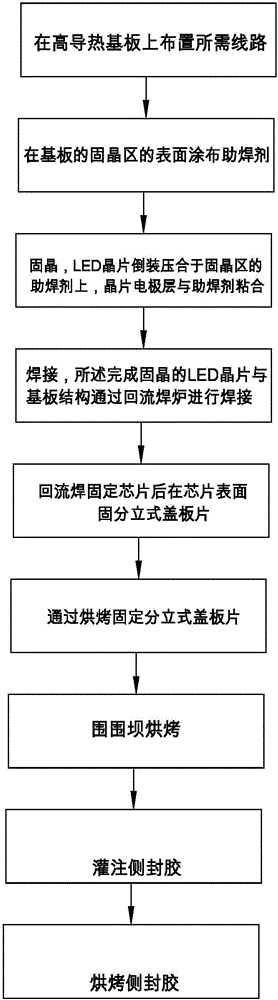

[0017] Such as figure 1 , figure 2 As shown, the flip-chip LED vehicle light provided by the present invention includes a substrate 1, a conductive circuit layer 2 is fixedly arranged on the top of the substrate 1, and a circle of dam glue 3 is arranged on the top of the conductive circuit layer 2, and the conductive circuit layer 3 located in the dam glue 3 Several chip units 4 are arranged at intervals on the circuit layer 2, and the gap between the dam glue 3 and each chip unit 4 is filled with side sealing glue 5, wherein each chip unit 4 includes a flip-chip LED chip 41, each The bottom of the flip-chip LED chip 41 is welded and fixed to the conductive circuit l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com