Cover body structure of storage battery

A battery and cover technology, applied in the direction of batteries, structural parts, battery pack components, etc., can solve the problems of unreasonable structure, difficult liquid injection of batteries, unsatisfactory exhaust performance, etc., to optimize the use performance and optimize liquid injection. performance, the effect of optimizing exhaust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

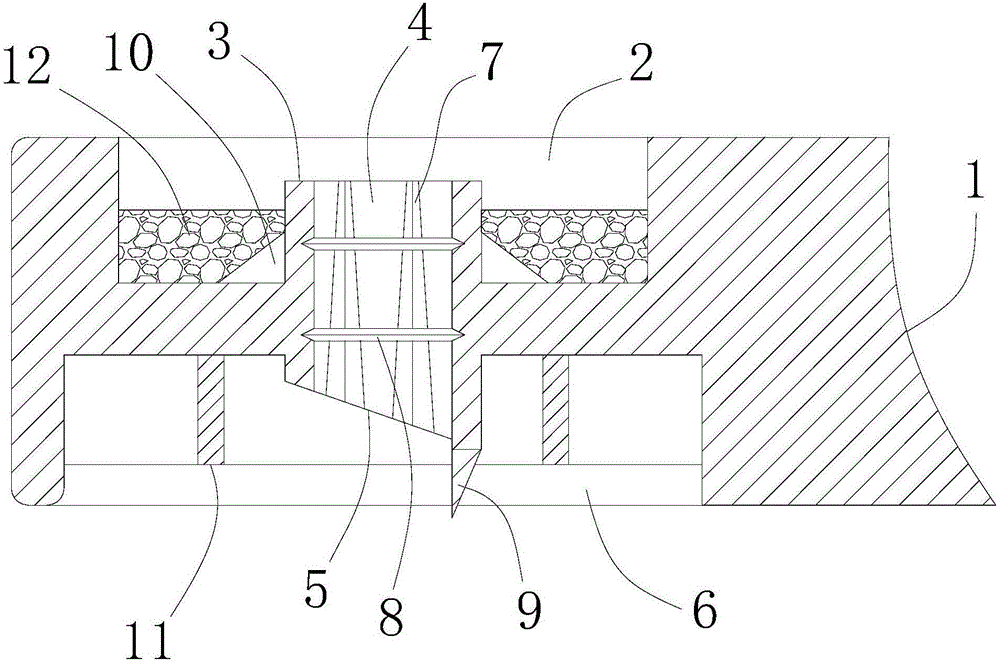

[0019] Such as figure 1 As shown, a battery cover structure includes a cover 1, a groove 2 is opened on the cover 1, a boss 3 is integrally provided in the groove 2, and the boss 3 penetrates the groove 2 The bottom wall of the bottom wall, and the boss 3 extends to both sides of the bottom wall of the groove 2, the cover 1 is also provided with a groove body 6, and the end of the boss 3 away from the groove 2 is located in the groove body 6 Inside, the material between the groove 2 and the groove body 6 forms the bottom wall of the groove 2, that is, the groove 2 and the groove body 6 share a piece of material, and the boss 3 extends to both sides of the bottom wall of the groove 2 means, The boss 3 protrudes to both sides of the common material, that is, a part of the boss 3 is located in the groove 2, and the other part of the boss 3 is located in the groove body 6, and the boss 3 and the cover body 1 are formed by a mold;

[0020] Such as figure 1 As shown, the boss 3 is...

Embodiment 2

[0027] This embodiment is a further optimization of the first embodiment, so that the cover body 1 has better performance. Such as figure 1 As shown, the lower end of the boss 3 is provided with a guide rib 9 extending along the axial direction of the boss 3 at the lowest position of the inclined opening 5, and the side wall of the guide rib 9 is parallel to the side wall of the liquid injection hole 4. together. The diversion ribs 9 and the cover body 1 are of an integrated structure, and the arrangement of the diversion ribs 9 facilitates the liquid entering the battery.

[0028] Such as figure 1 As shown, a reinforcing rib 10 is integrated between the boss 3 and the bottom wall of the groove 2 . The arrangement of the ribs 10 improves the strength of the cover body 1 , thereby prolonging the service life of the cover body 1 .

[0029] Such as figure 1 As shown, ribs 11 are integrally provided in the tank body 6 , and the ribs 11 are arranged in the tank body 6 in a gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com