Ribbed And Apertured Fluoroplastic Support Sheet For A Filter Substrate And Method Of Making Same

A technology of sheet-like objects and supports, applied in chemical instruments and methods, separation methods, membrane filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

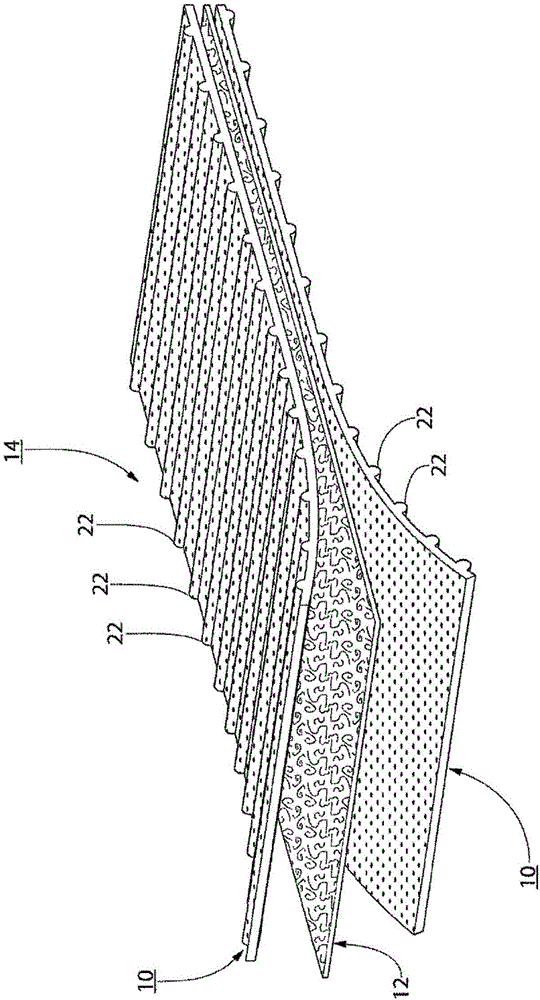

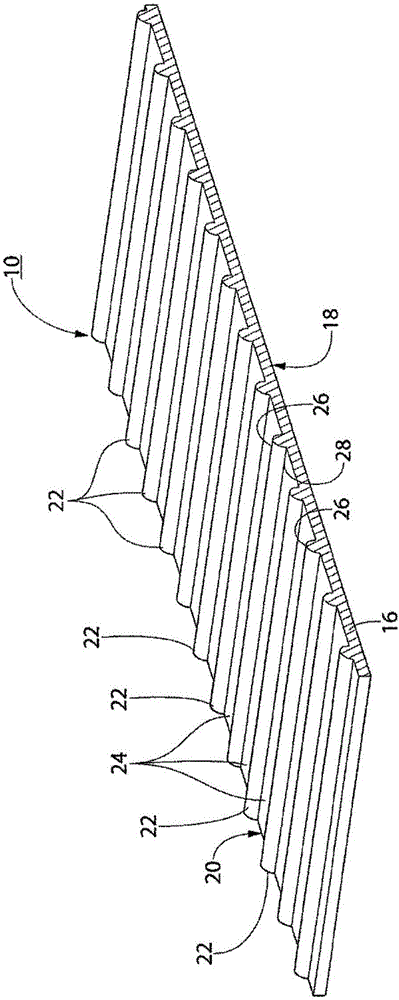

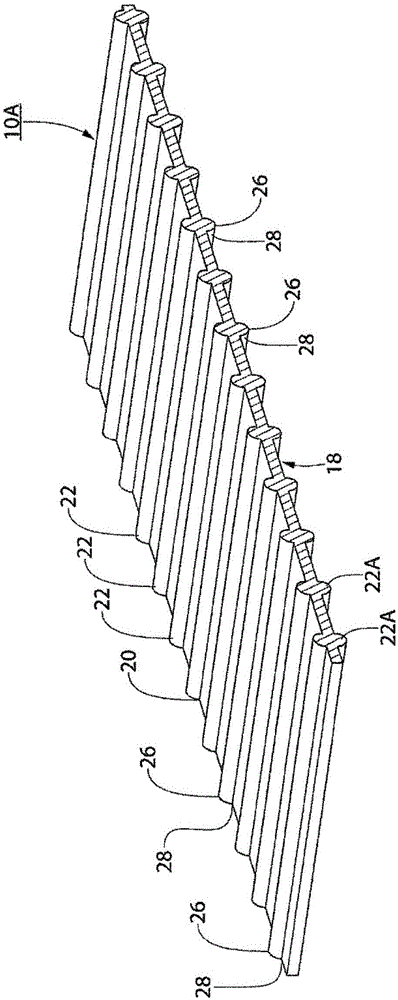

Image

Examples

Embodiment Construction

[0027] Holes punched through its entire thickness referred to throughout this application including the claims "in a predetermined pattern unaffected by the structure of the support sheet" means that the support sheet is not embossed or patterned in Others are provided with cutouts or weakened areas intended to constitute areas where holes are created or formed. The predetermined pattern of holes of the present invention may very well be set, selected or determined by the ribbed sheet, but the structure of the ribbed sheet is not responsible for providing or establishing the predetermined pattern of holes. In a preferred embodiment, the predetermined pattern of holes is provided by a predetermined pattern of punching members of a punching press for producing holes in the ribbed sheet.

[0028] References throughout this application to "filter media" or "filter substrate" are components of the filter member of the present invention which may have any desired configuration and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com