Flight malfunction determining method based on simulation

A fault determination and failure technology, applied in the field of flight failure determination based on simulation, can solve problems such as difficulty, impact on test flight efficiency, and high risk, and achieve the effect of ensuring flight safety, improving test flight efficiency, and reducing test flight risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

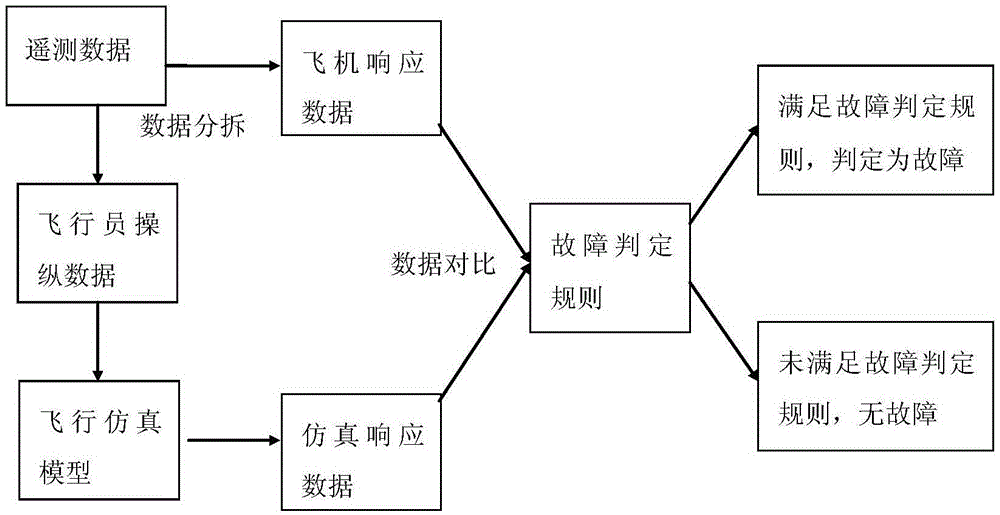

[0011] Combine below figure 1 The specific implementation manner of this patent is described in detail:

[0012] Step 1: Create a high-fidelity aircraft simulation model with fault and special situation simulation

[0013] For different flight test tasks, consider all the possible faults and special situations, establish the corresponding fault special situation database, on this basis, establish the aircraft simulation model that can simulate the corresponding faults and special situations;

[0014] Step 2: Determine the corresponding fault judgment rules

[0015] After establishing the simulation model of faults and special conditions, the impact of each fault and special situation on a specific flight test task is simulated and calculated, and the corresponding fault judgment rules are determined on the basis of comprehensive analysis of the impact of each fault and special situation;

[0016] Step 3: Give emergency treatment methods for specific faults and special situat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com