Plug-in type hydraulic and pneumatic integrated teaching experiment table control system

A control system and test bench technology, applied in the field of machinery, can solve the problems of backward control technology, unable to reflect hydraulic and pneumatic technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

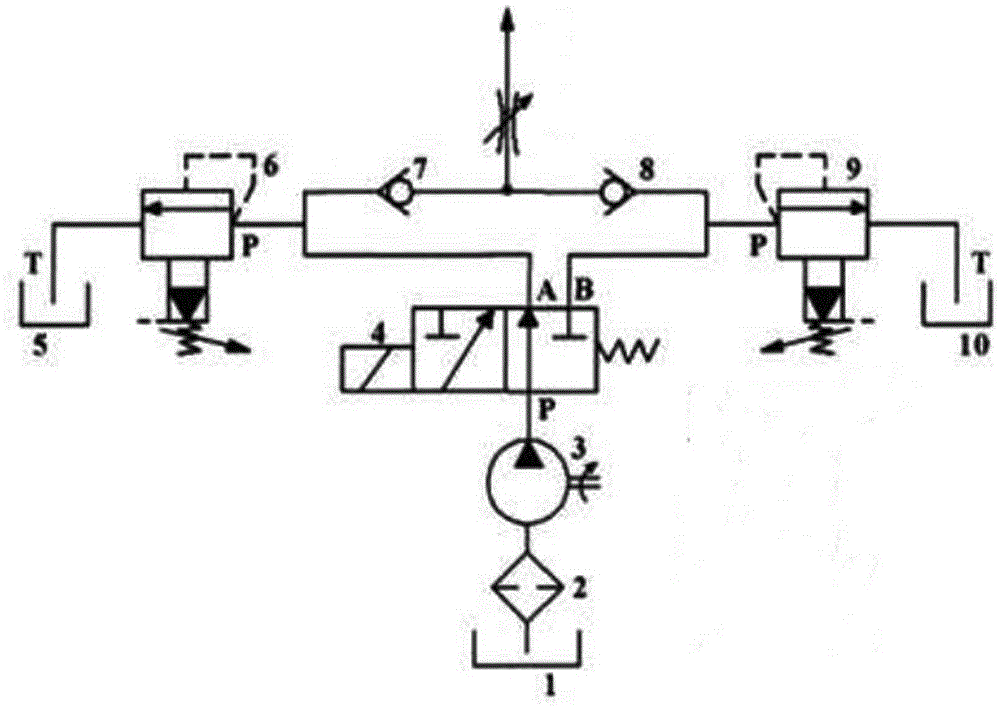

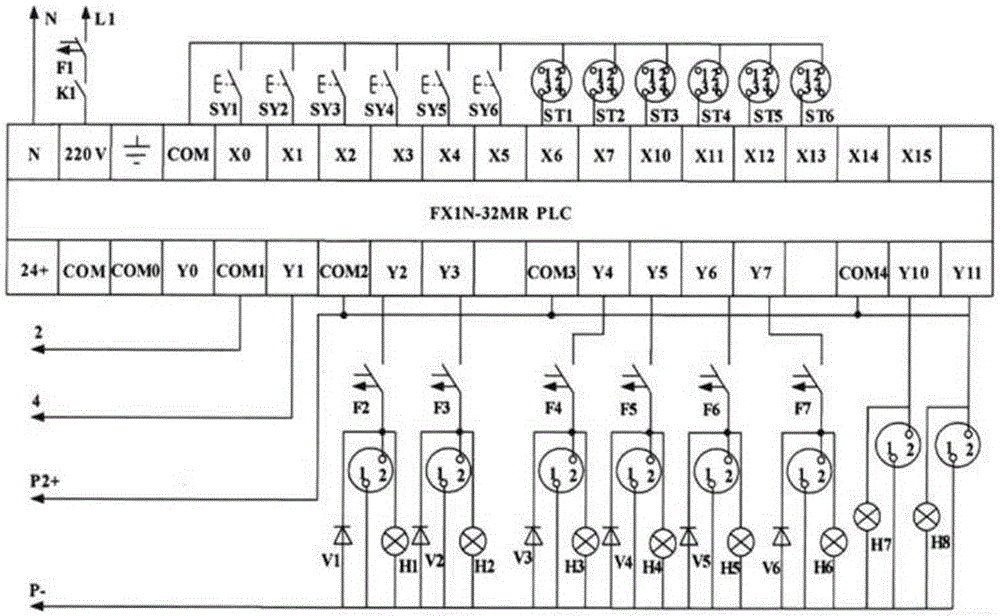

[0015] Such as figure 1 , The control system of the test bench includes two parts: the hydraulic source pressure control and the electrical control, and the electrical control is divided into two parts: the strong current control system and the weak current control system. Considering the compact structure and the separation of strong and weak electricity, the hydraulic source pressure control part and the strong electric control part are placed on the lower part of the experimental platform, and the weak current control part is placed on the upper part of the console.

[0016] The hydraulic source pressure control system is equipped with a flow control valve, which can adjust the required flow according to requirements. A quantitative vane pump 3 is used to supply oil to the system, and two kinds of system maximum pressures can be obtained through the reversing cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com