Pumping module and pump thereof

A technology of pumps and connectors, applied in the field of pump modules and their pumps, can solve the problems of increasing the installation cost of the liquid cooling system, lack of flexibility, and limitation of the maximum output flow, etc., and achieve the effect of fast and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

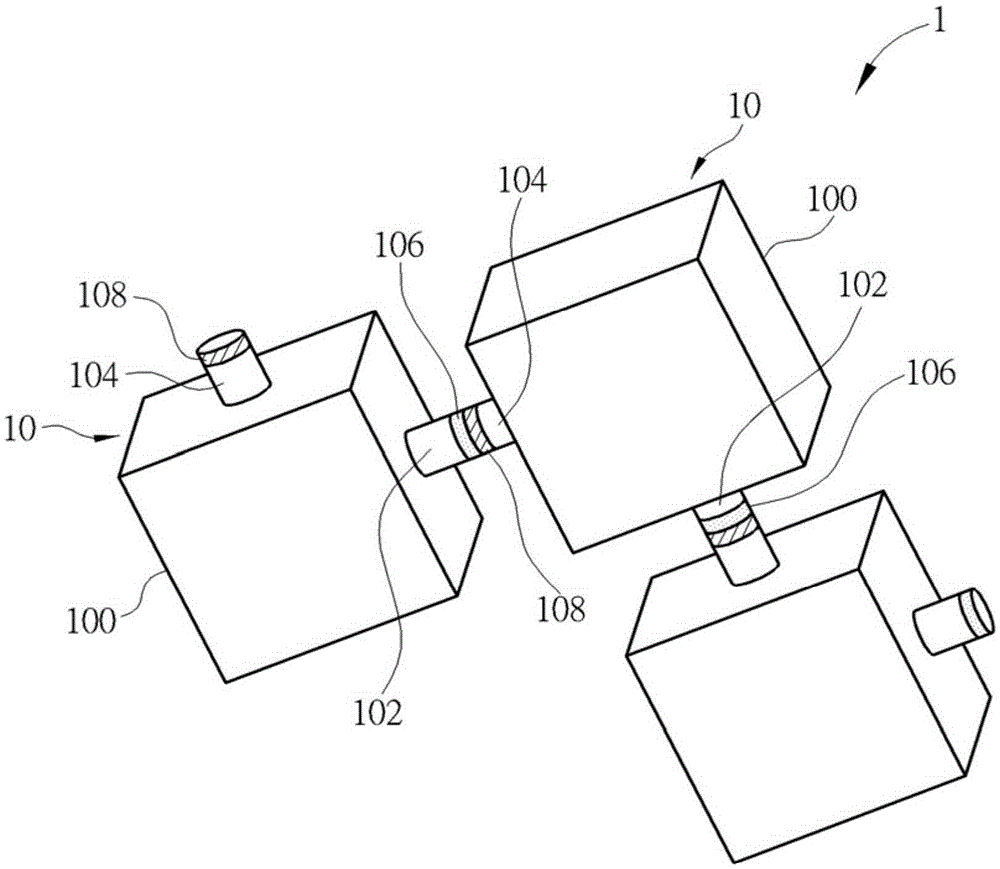

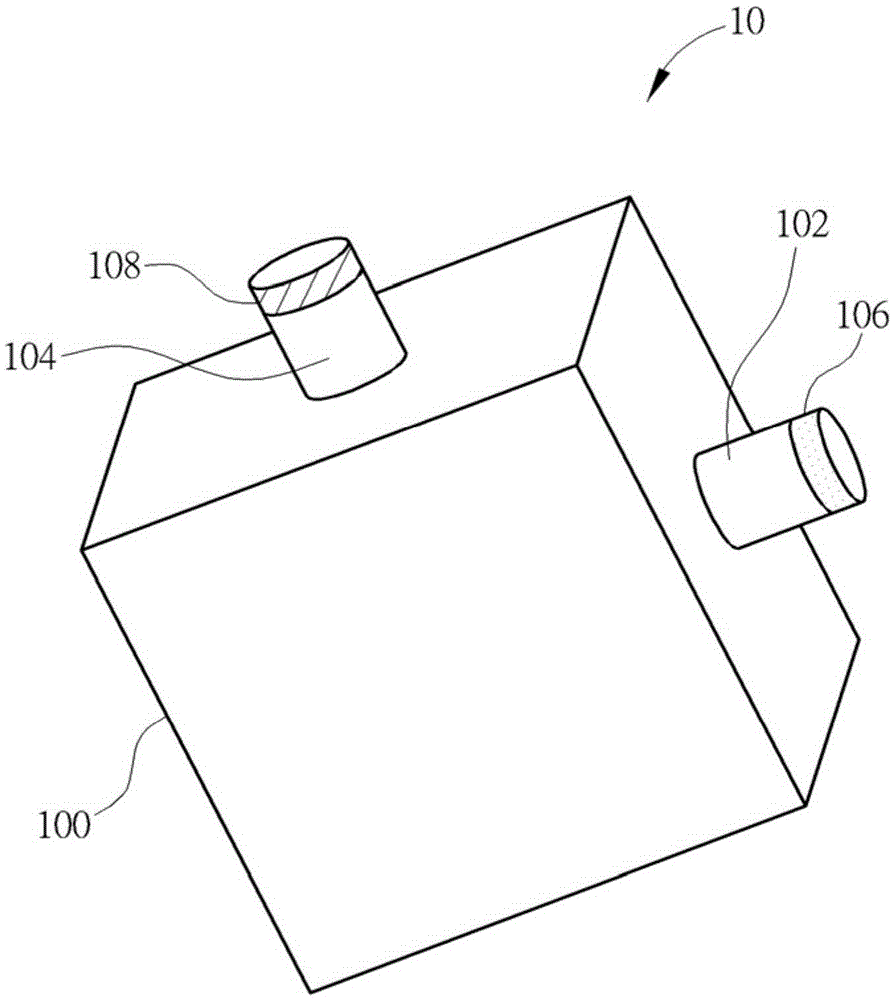

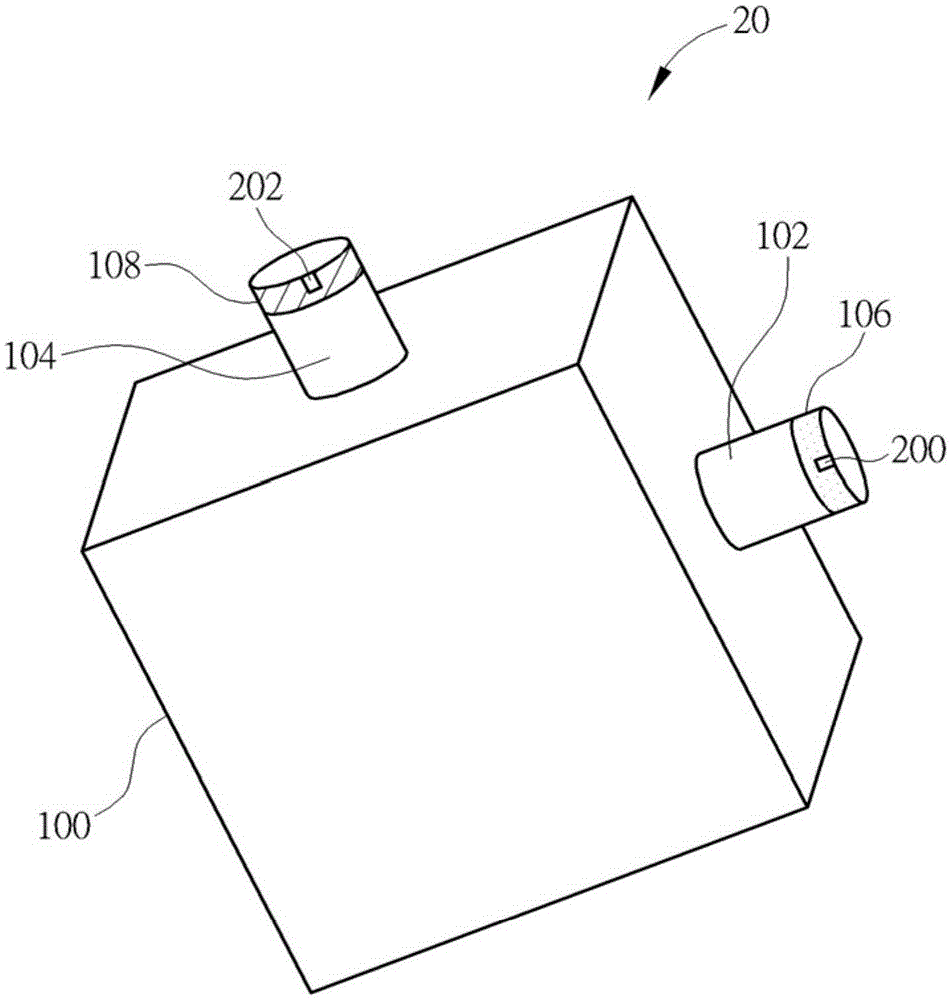

[0032] see figure 1 as well as figure 2 , figure 1 is a schematic diagram of a pump module 1 according to an embodiment of the present invention, figure 2 for figure 1 A schematic diagram of a pump in 10.

[0033] Such as figure 1 and figure 2 As shown, the pump module 1 includes a plurality of pumps 10 . Each pump 10 includes a pump body 100 , a water outlet 102 , a water inlet 104 , a first connecting piece 106 and a second connecting piece 108 . The water outlet 102 and the water inlet 104 respectively extend from the periphery of the pump body 100 . The first connecting member 106 is disposed on the water outlet 102 , and the second connecting member 108 is disposed on the water inlet 104 . In this way, the first connector 106 of one of the pumps 10 can be detachably connected to the second connector 108 of the other pump 10, so that each pump 10 can be connected to any one of the pumps 10. ,Such as figure 1 shown.

[0034] In other words, since the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com