Switch plug bush full-linked structure of three-position dipolar oblate plugs and three-position five-hole plugs

A five-hole socket and five-hole plug technology, applied in the direction of contact parts, electrical components, coupling devices, etc., can solve the problems of poor stability, easy occurrence of de-soldering, de-soldering, etc., and achieve efficient power supply mode and stable connection mode. , the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below with reference to the accompanying drawings.

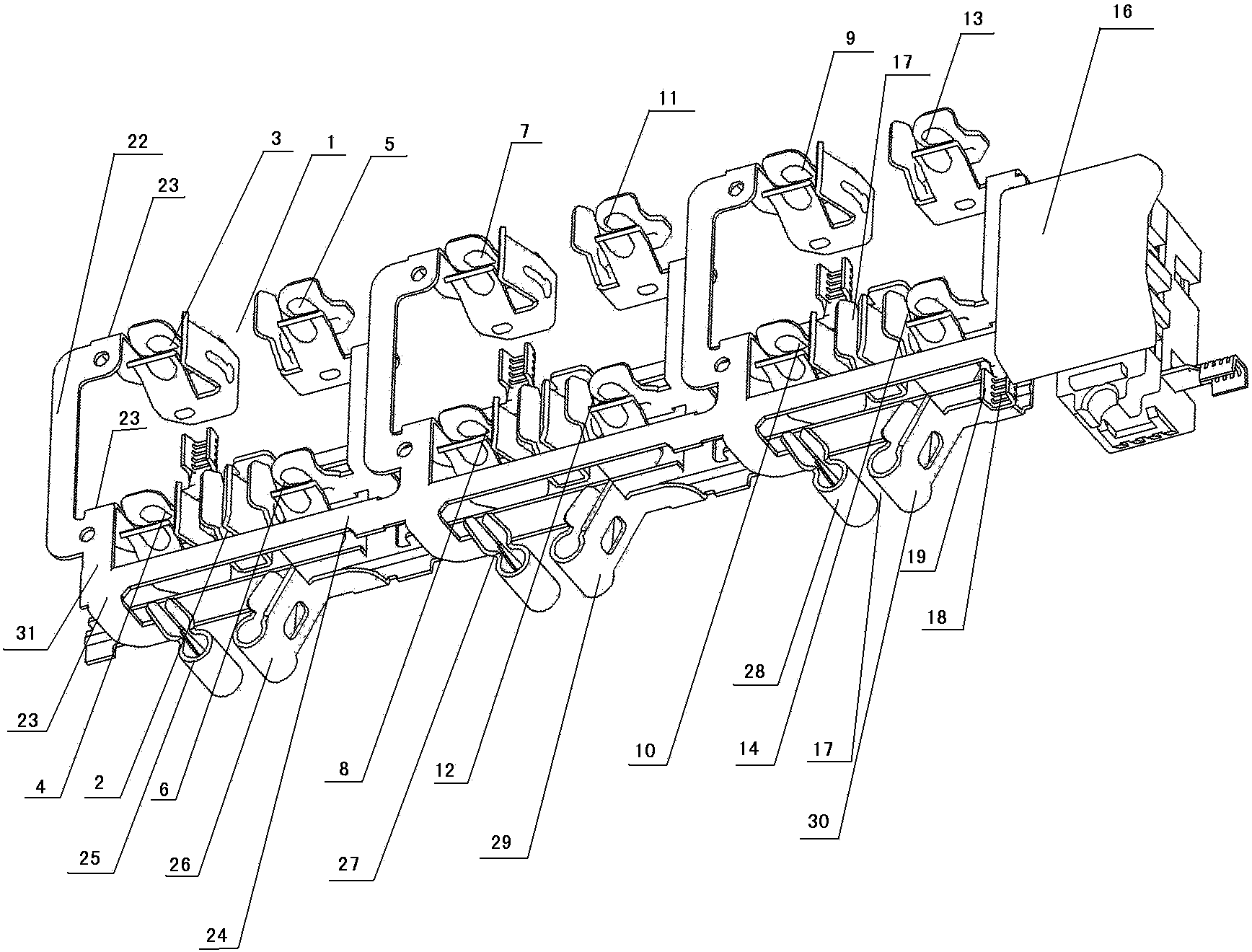

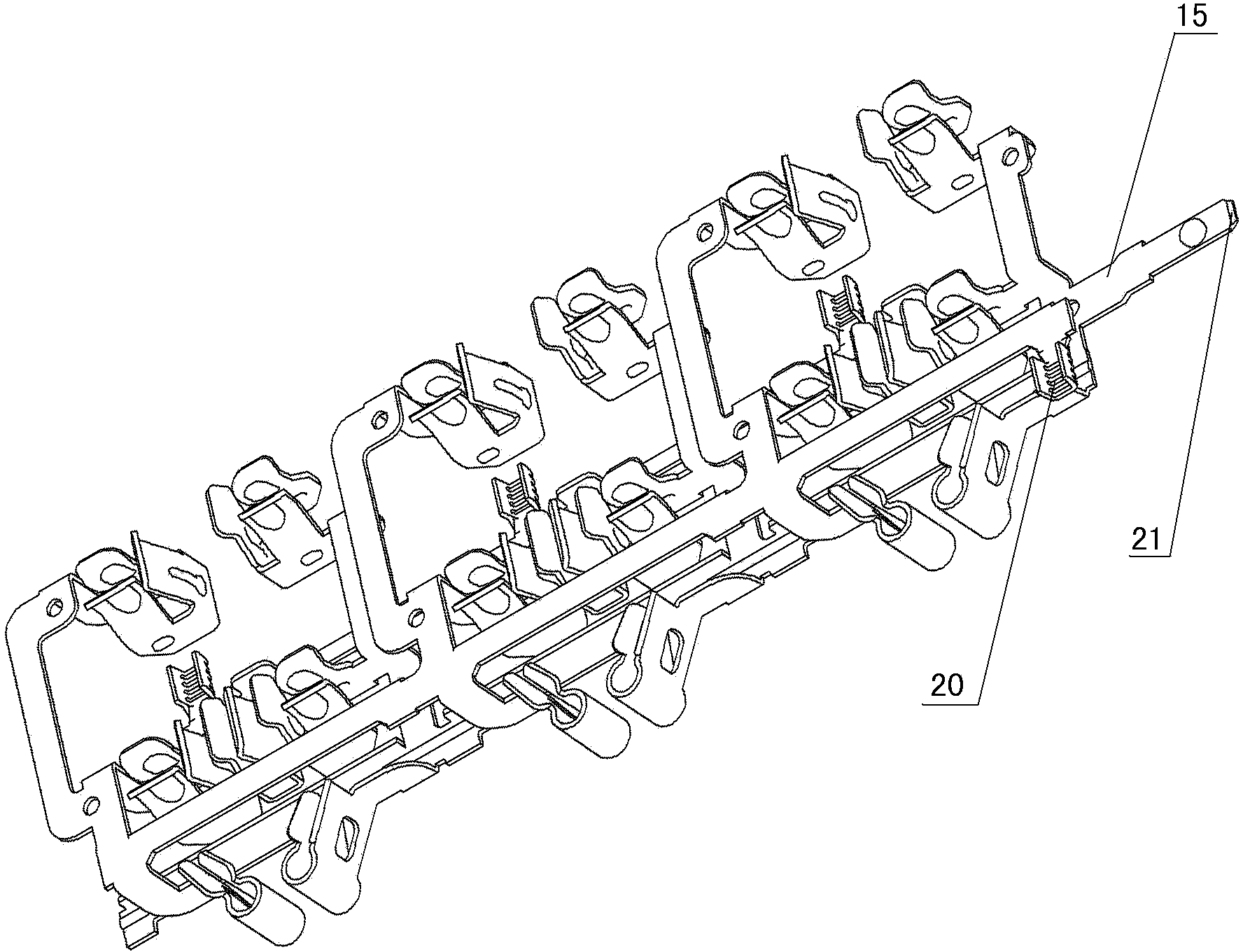

[0009] The present invention is a full conjoined structure of three-position two-round plug and three-position five-hole switch socket, which is different from the prior art in that the all-conjoined structure consists of at least three sets of two-pole oblate sockets 1 and at least Three sets of five-hole sockets 2 are formed, in which the first N-pole socket 3 of the first group of two-pole oblate sockets 1 is connected with the second N-pole socket 4 and the first oblique N-pole socket of the first group of five-hole sockets 2 25 connection, the first L-pole plug 5 of the first group of two-pole oblate sockets 1 is connected with the second L-pole socket 6 and the second oblique L-pole socket 26 of the first group of five-hole sockets 2, three sets of two-pole The oblate sockets 1 are distributed horizontally and linearly, and the three groups of five-hole sockets 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com