Flushing pipe and flushing equipment

A technology for flushing tubes and equipment, used in enema/irrigator, medical science, surgery, etc., can solve problems such as difficulty and achieve sufficient flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

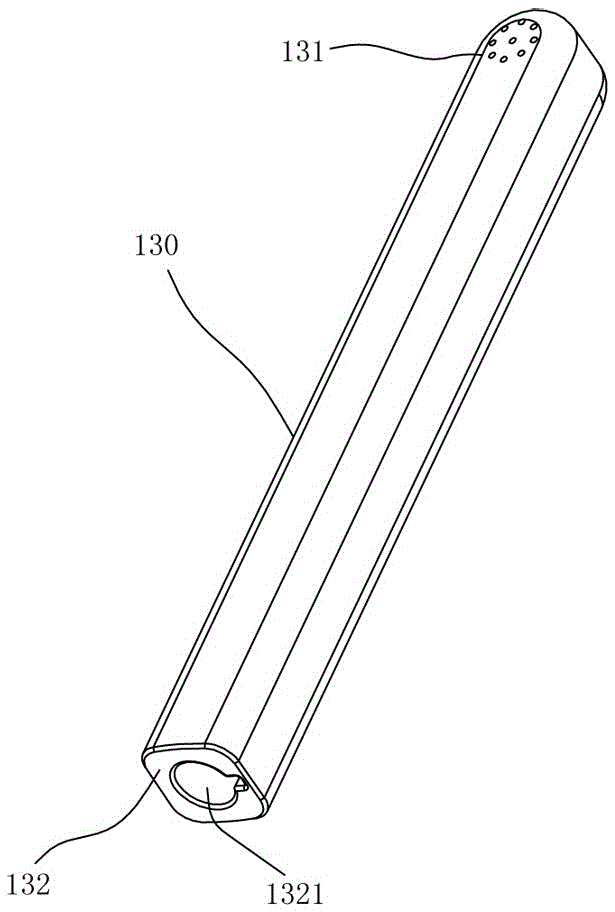

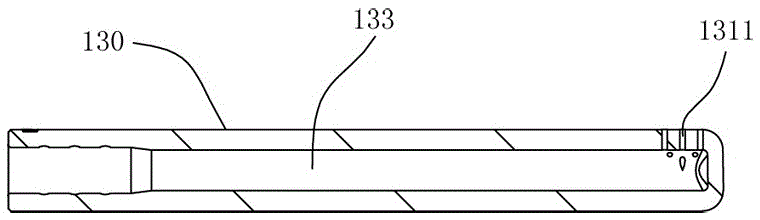

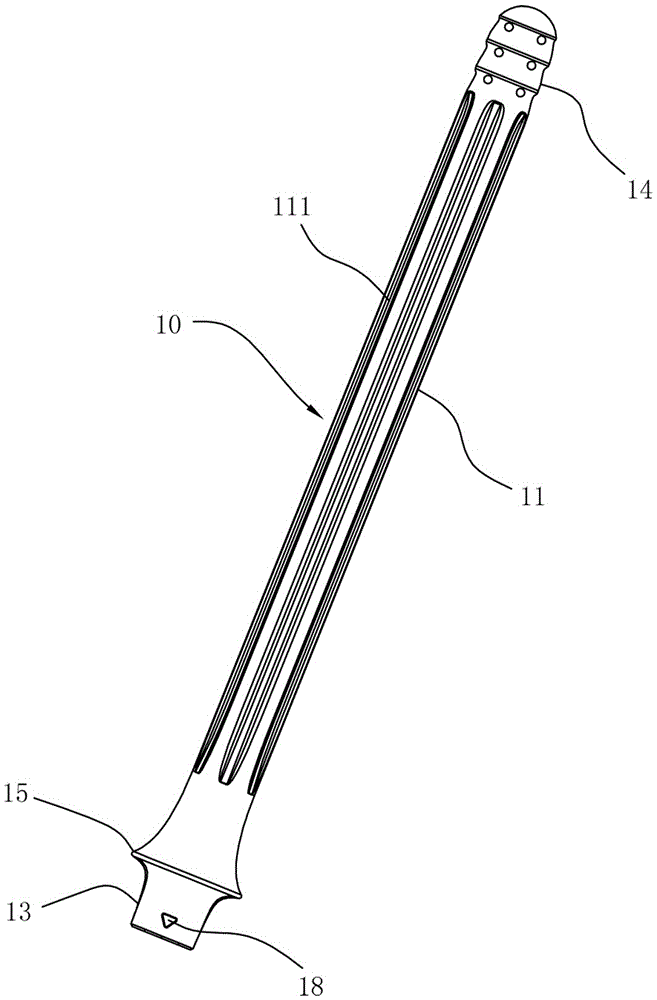

[0029] Such as image 3 As shown, it is a structural view of a preferred embodiment of the flushing pipe in the present invention. The flushing tube 10 disclosed in this preferred embodiment is intended to be connected to a flushing device 20 (refer to Figure 6 shown) to deliver the fluid to the designated location, such as the affected area to be rinsed.

[0030] Such as image 3 , Figure 4 , Figure 5 As shown, the flushing tube 10 includes a tube body 11 and a liquid channel 12 disposed in the tube body 11 , wherein the outer surface of the tube body 11 is configured as a circle. The tube body 11 includes a connecting end 13 and a liquid outlet 14 , the connecting end 13 is provided with a liquid inlet 17 communicating with the liquid channel 12 , and the connecting end 13 is used for connecting with an external flushing device 20 . In this embodiment, the pipe wall of the liquid outlet 14 is provided with 12 liquid injection ports 141 communicating with the liquid c...

specific Embodiment 2

[0039] Such as Figure 6 As shown, it is a structural view of a preferred embodiment of the flushing device with the flushing pipe in the present invention. The flushing device 20 includes a main body 21 , a liquid storage tank 22 and a flushing pipe 10 , and the main body 21 is connected to the liquid storage tank 22 and the flushing pipe 10 respectively. Such as Figure 7 As shown, the main body 21 is provided with a control circuit 211, a pump 212, a heating element 213, a power supply 214 and a temperature sensor 215. The pump 211, the heating element 213, the power supply 214 and the temperature sensor 215 are all electrically connected to the control circuit 211. The pump 211 is adapted to suck the liquid in the liquid storage tank 22 to the flushing pipe 10 and flow out from the liquid spray port 141 .

[0040] In this embodiment, the heating element 213 itself is used for both heating and detecting its own temperature, the heating element 213 is used for heating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com