Multi-station adjustable servo valve forward and reverse flushing device

A forward and reverse flushing, servo valve technology, applied in servo motor components, fluid pressure actuating devices, cleaning hollow objects, etc., can solve the problems affecting the production progress of servo valves, low flushing efficiency, occupation and other problems, and improve flushing production efficiency , The effect of rapid flow adjustment and quick and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

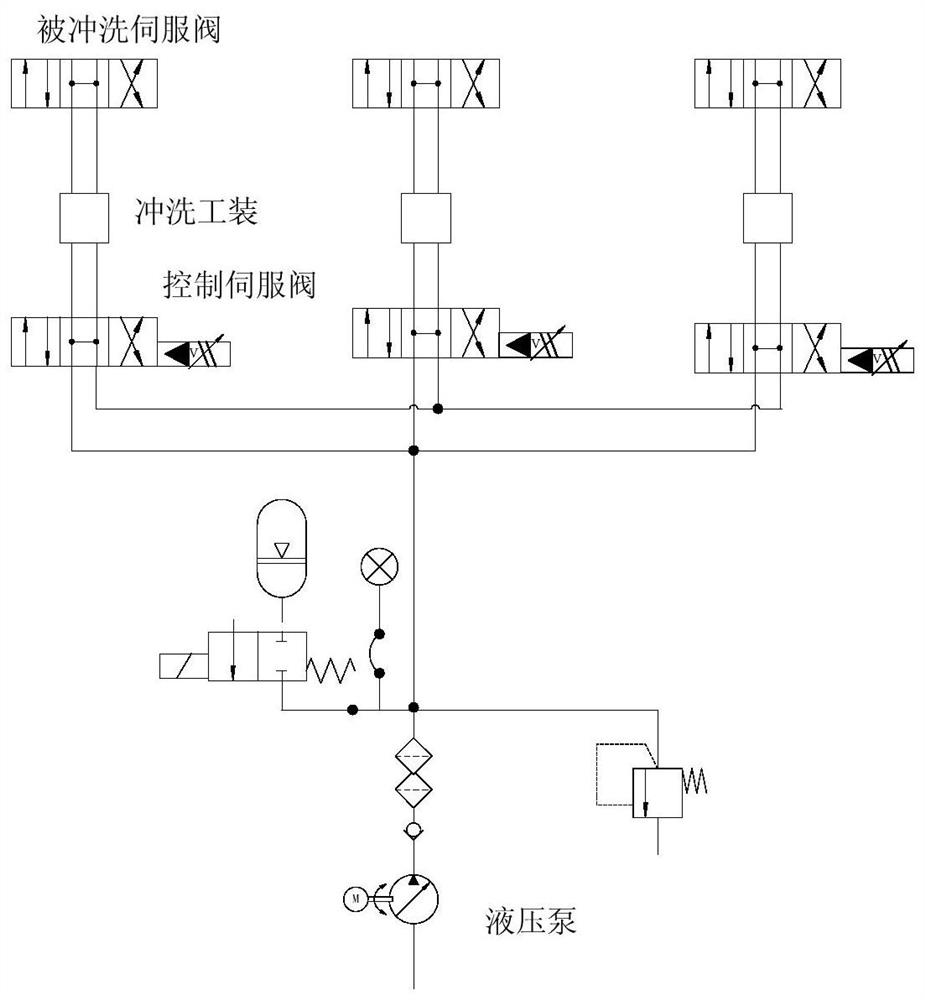

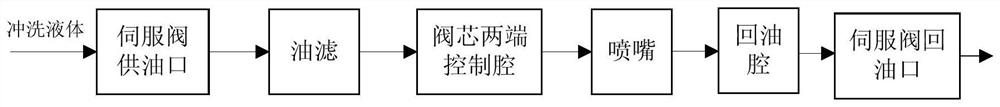

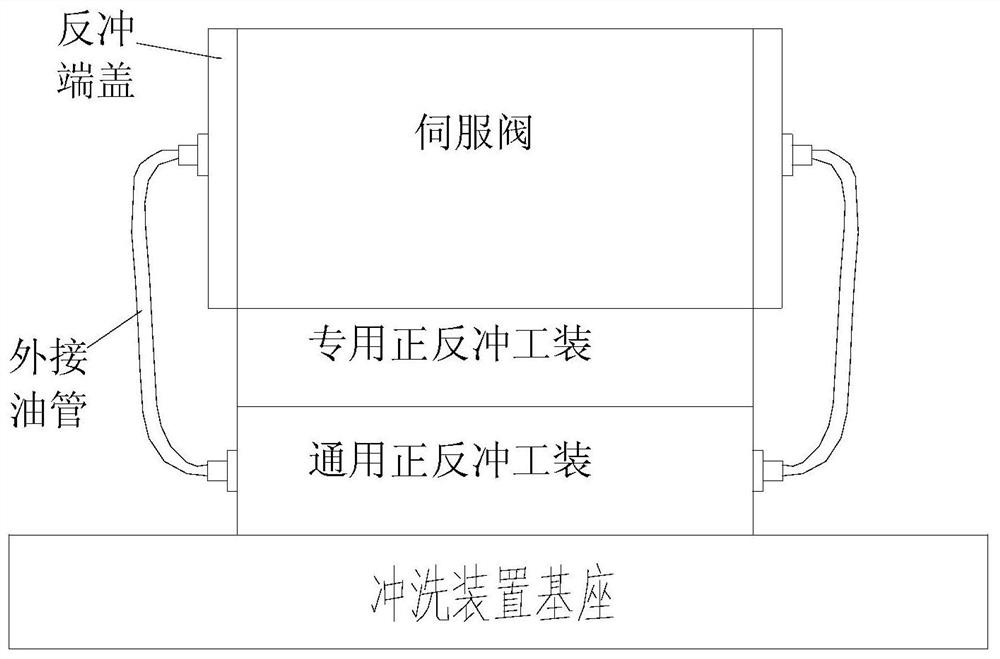

[0033] Such as figure 1 , 3 As shown, the multi-position adjustable servo valve positive and negative flushing device includes a hydraulic energy module, a flushing parameter control module, and flushing tooling;

[0034] The adjustable hydraulic pump and variable frequency motor in the hydraulic energy module can ensure that the system pressure of the device can be adjusted within the range of 0-16MPa, and the flow rate can be adjusted from 0-20L / min. The secondary filter is installed at the pump outlet to ensure the oil in the flushing system cleanliness.

[0035] The flushing parameter control module includes a control servo valve and a servo amplifier. The servo amplifier can set the input current of the control servo valve so that the control servo valve works according to the set parameters. The parameter setting of the servo valve amplifier is convenient, and it can be quickly set and adjusted to control the working state of the servo valve. The servo amplifier can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com