Fully automatic table tennis grinding, shaping, sorting and screening equipment

A kind of screening equipment and table tennis technology, which is applied to balls, rackets, sorting, etc., can solve the problems of high technical requirements for operators, unstable product quality, and large space for use in venues, and achieve reduced scrap rate, compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

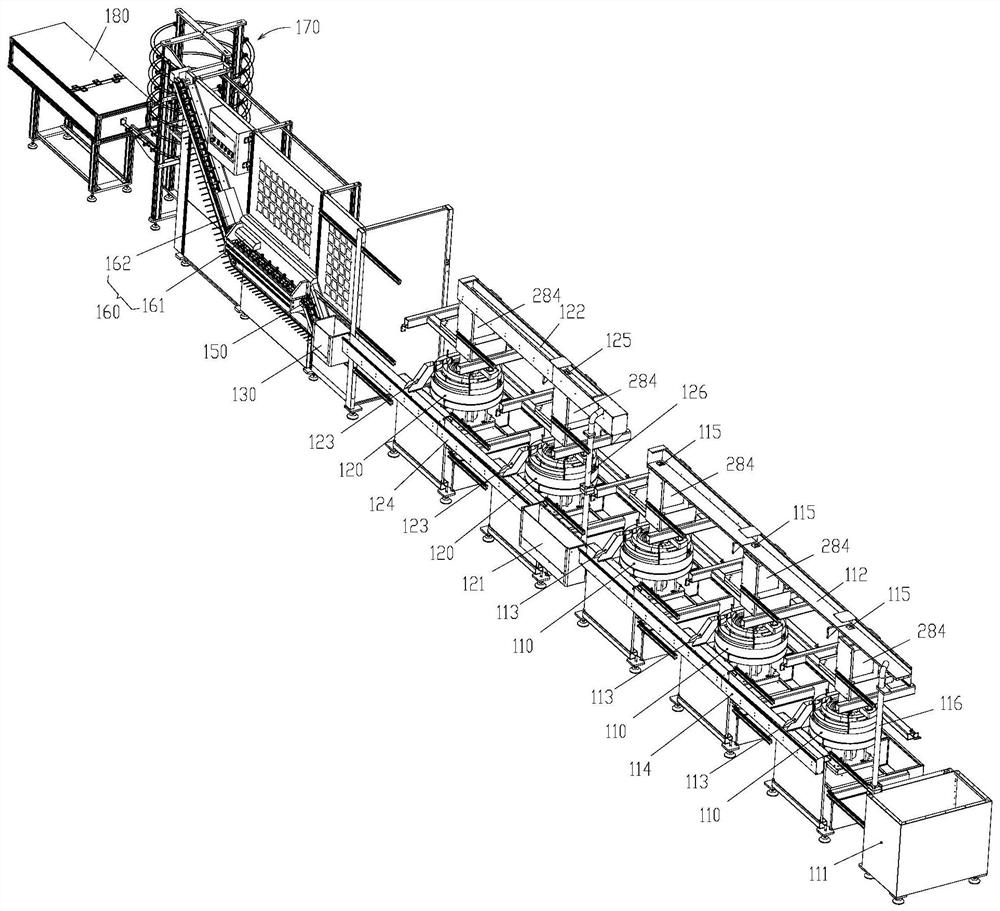

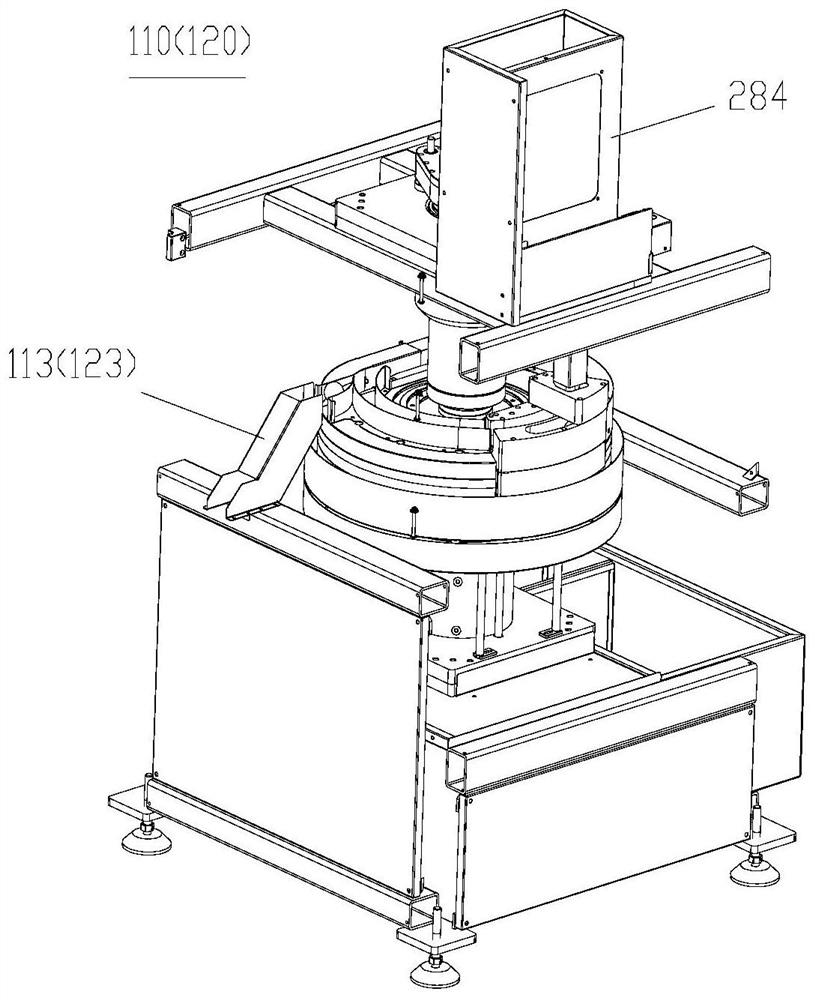

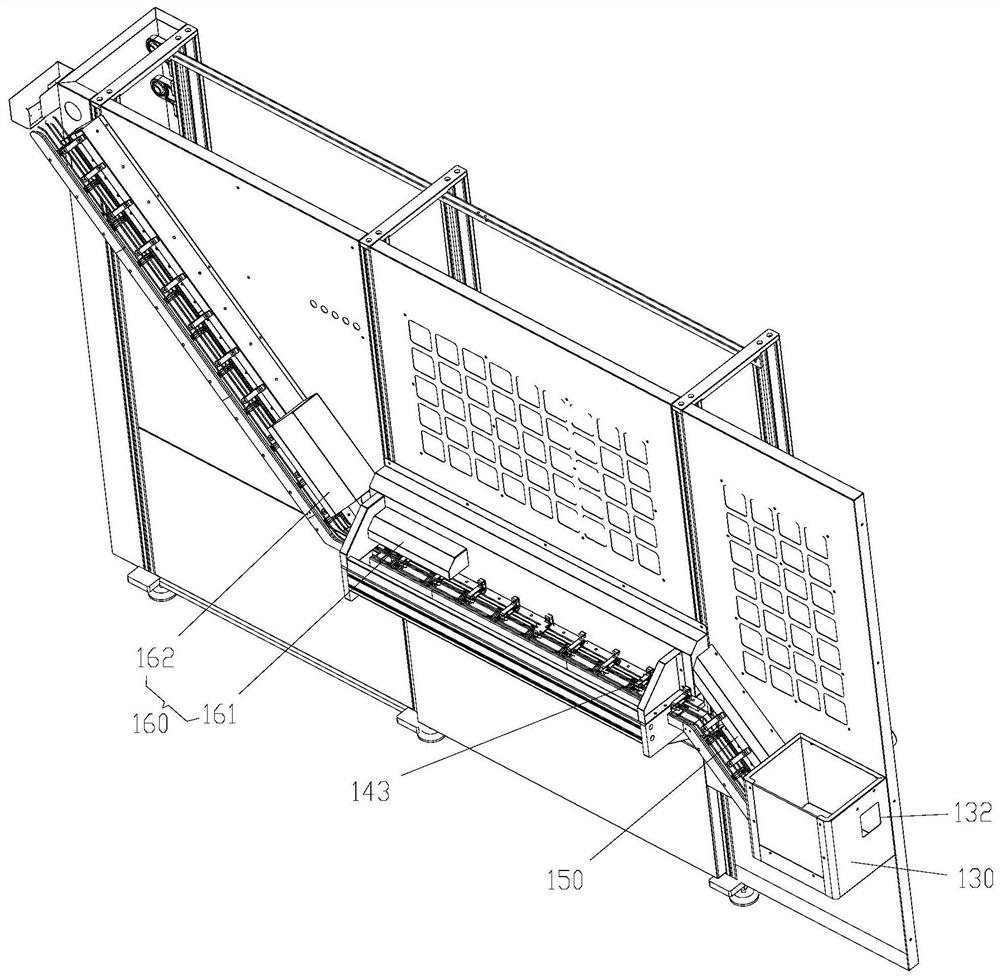

[0046] See attached Figure 1-8 As shown, a fully automatic table tennis grinding, shaping, sorting and screening equipment of this embodiment integrates grinding, cleaning, drying and sorting and screening. It specifically includes primary grinding ball storage box 111, three primary grinding machines 110, fine grinding ball storage box 121, two fine grinding machines 120, washing ball storage box 130, conveying chain 140, washing machine 150, dewatering dryer 160 , slide rail frame 170, measuring and screening machine 180, the spheroid meeting that just grinds through primary grinder 110 enters fine grinder 120 again and grinds, and the quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com