Car sealing strip cutoff equipment for car field

A technology for automobile sealing strips and cutting equipment, which is applied in metal processing and other directions, can solve the problems of the buffering effect of the cutting knife, the increase of cutting errors, and the hidden dangers of workers' safety, so as to achieve the effect of prolonging the service life, preventing breakage and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

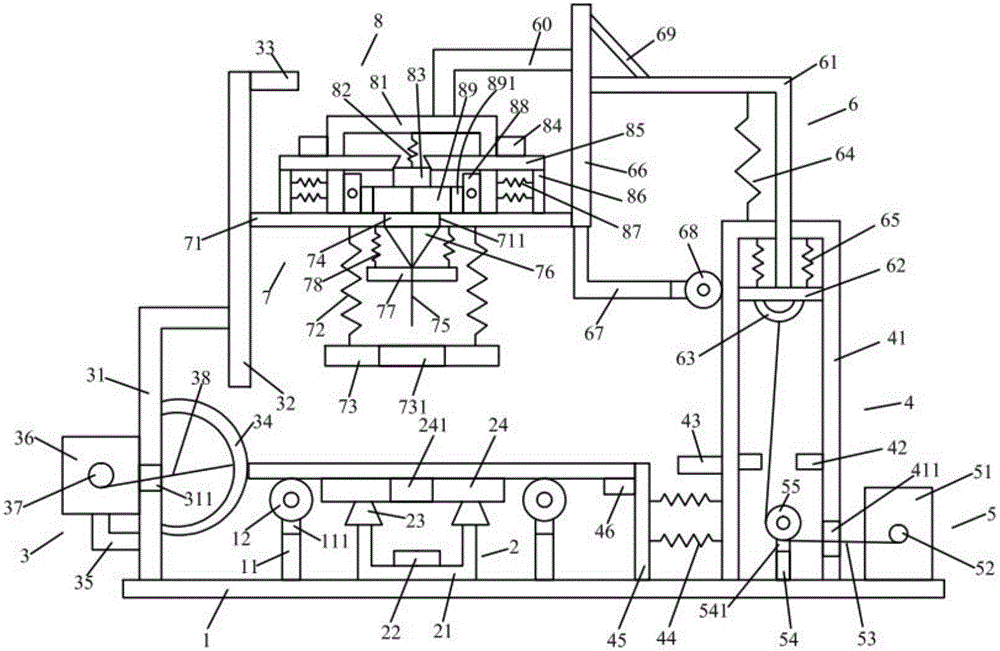

[0018] The following will make a clear and complete description of the automotive sealing strip cutting device used in the automotive field in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the automobile sealing strip cutting equipment used in the automotive field of the present invention includes a base plate 1, a support device 2 located above the base plate 1, an adjustment device 3 located on the left side of the support device 2, and an adjustment device 3 located on the right side of the support device 2. The positioning device 4 on the side, the motor device 5 arranged on the bottom plate 1, the bracket device 6 above the positioning device 4, the buffer device 8 on the left side of the bracket device 6 and the buffer device 8 below The cutting device 7.

[0020] Such as figure 1 As shown, the base plate 1 is rectangular parallelepiped and placed horizontally. The base plate 1 is provided with first support rods 11 on the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com