Cement production stirring and mixing equipment with material crushing plant

A material crushing, stirring and mixing technology, which is used in clay preparation equipment, mixing operation control, cement mixing equipment, etc., can solve the problems of uneven mixing, complicated operation and long mixing time of mixing equipment, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

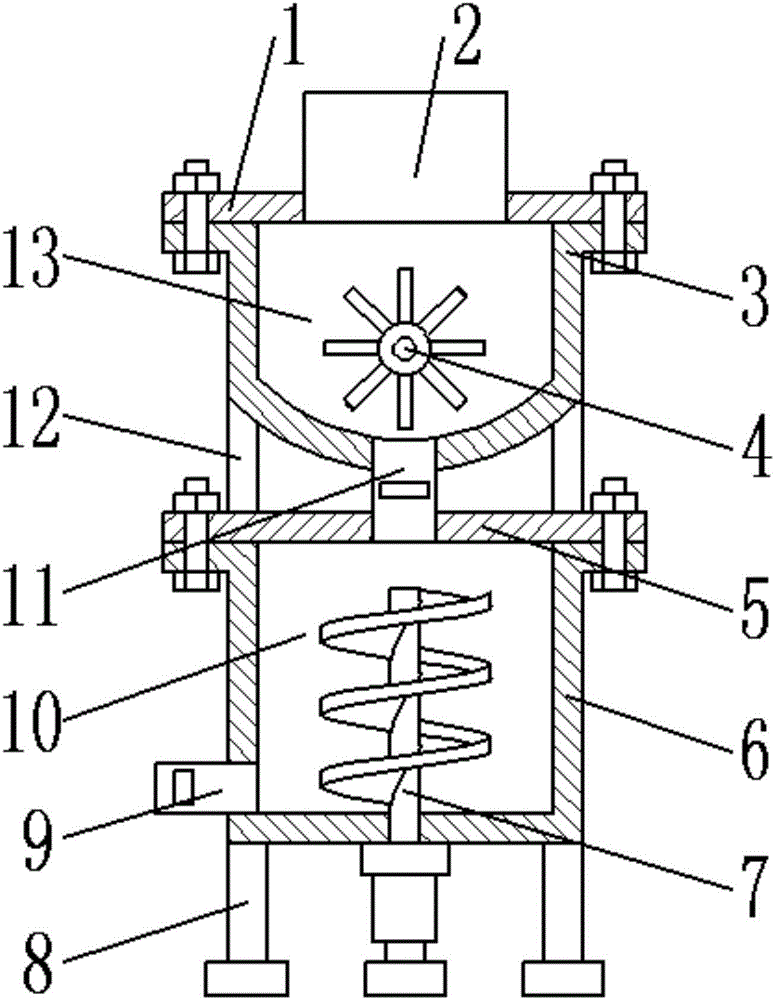

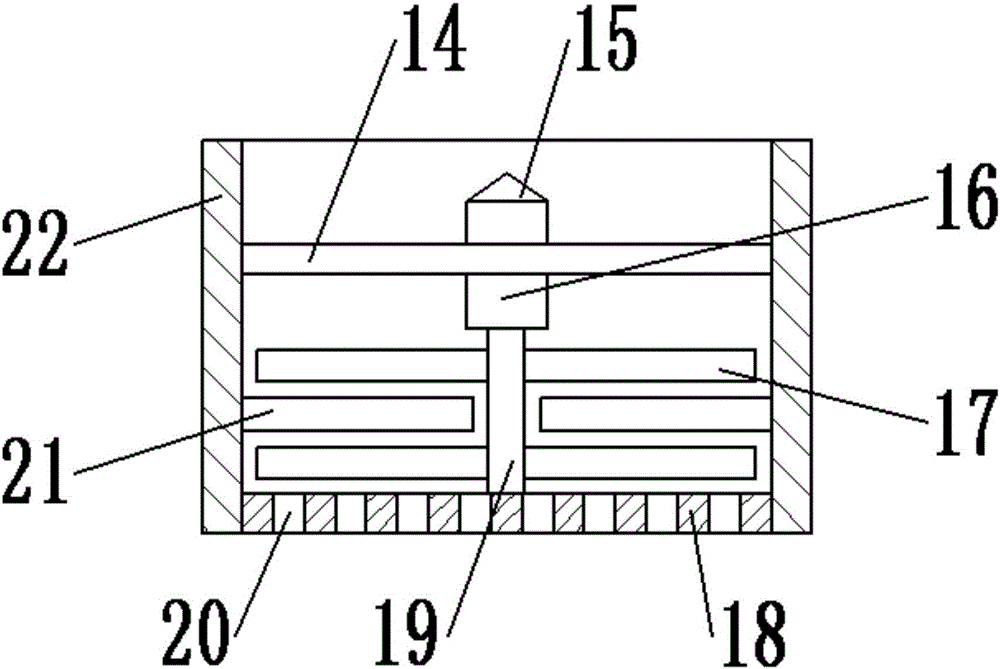

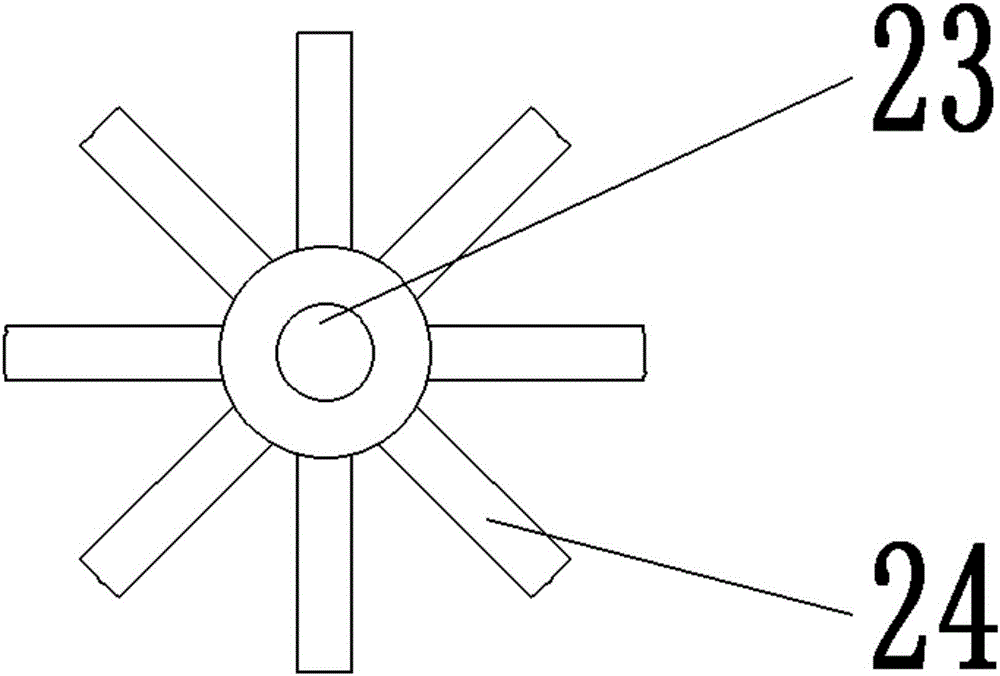

[0018] see Figure 1-4 , a mixing equipment for cement production with a material crushing device, comprising a first mixing tank 3 and a second mixing tank 6; the first mixing tank 3 and the second mixing tank 6 are made of stainless steel, the first mixing tank 3 is set as a hollow cylinder with a square cross-section, the bottom is set as a semi-cylindrical shape, and the second mixing tank 6 is set as a hollow cylinder; the inside of the first mixing tank 3 is set as a first mixing chamber 13, and a first mixing chamber 13 is set at the top opening. The mixing tank cover 1; the inside of the second mixing tank 6 is set as a second mixing chamber 10, and the top opening is provided with a second mixing tank cover 5; the first mixing tank cover 1 and the second mixing tank cover 5 are connected by bolts The mutual screwing of the nut and the fir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap