Efficient stirring and mixing equipment for chemical product manufacturing

A chemical product, stirring and mixing technology, used in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of inability to obtain a good reaction, poor mixing effect, etc., to facilitate mixing, improve mixing quality, and efficient mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

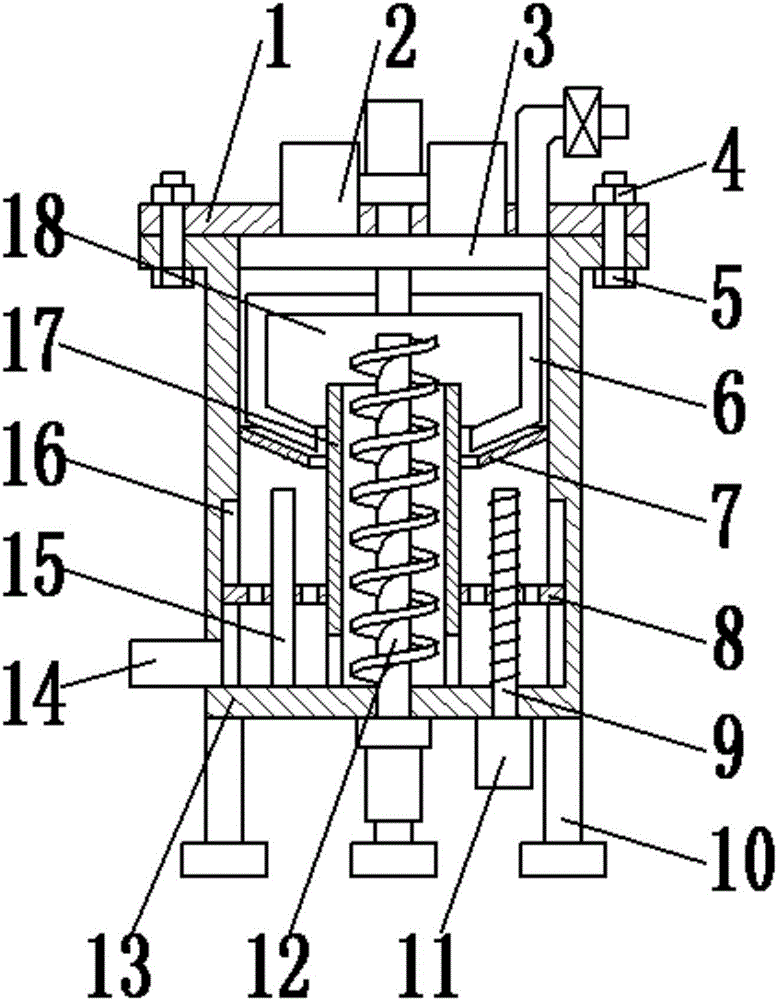

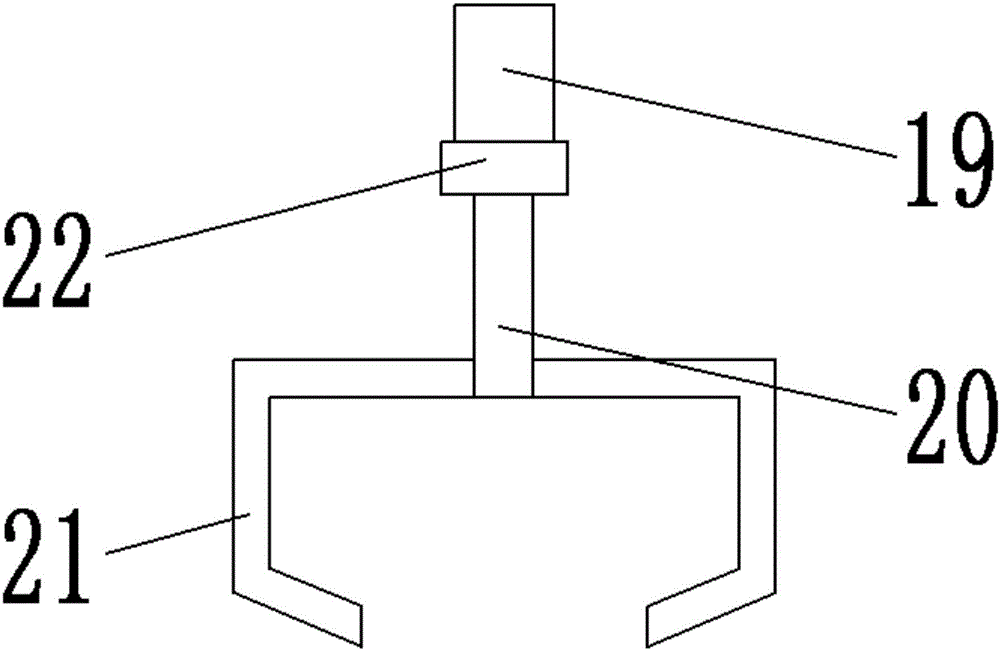

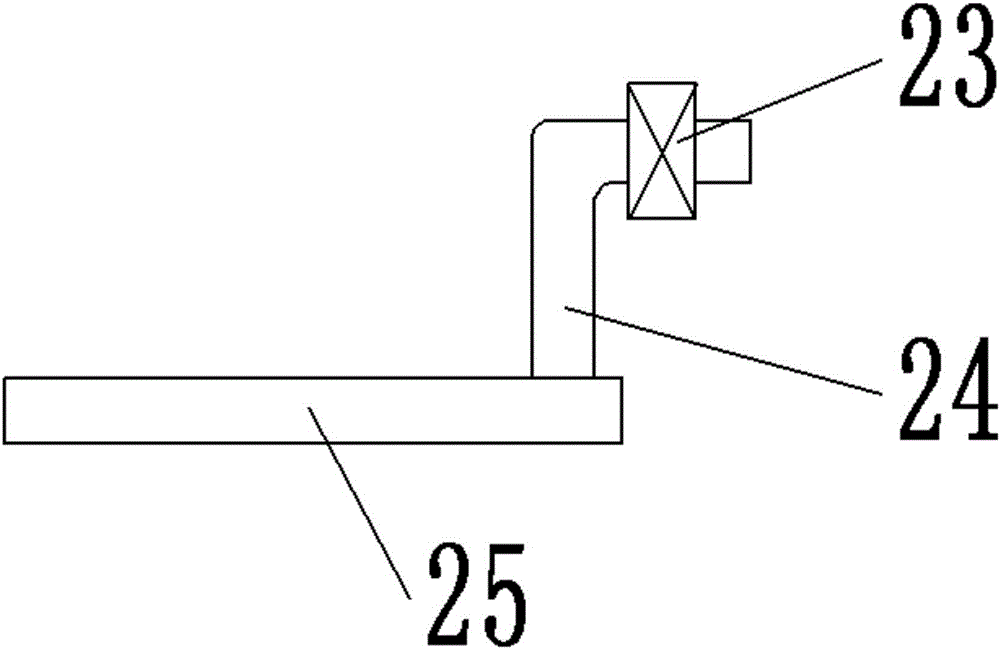

[0023] see Figure 1-7 , a high-efficiency stirring and mixing equipment for the manufacture of chemical products, including a tank body 13; the tank body 13 is set as a hollow cylinder made of stainless steel, the interior is set as a stirring chamber 18, and an upper cover 1 is set at the top opening; The upper cover 1 is connected with the tank body 13 through the mutual screwing of the bolt 5 and the nut 4; the upper cover 1 is provided with a solid material feed pipe 2 and a liquid material feed device 3; the solid material feed pipe 2 is provided with There are two sets, symmetrically arranged on the left and right sides of the upper cover 1; the liquid material feeding device 3 is composed of a spray plate 25 and a liquid inlet pipe 24; the spray plate 25 is fixed on the lower surface of the upper cover 1, and The liquid pipe 24 is connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap