A kind of iron ion stabilizer for multifunctional acidification and preparation method thereof

An iron ion stabilizer and multi-functional technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as unreported multi-functional products, improve the accuracy of liquid dispensing, and simplify the liquid dispensing process. , the effect of reducing the waste of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

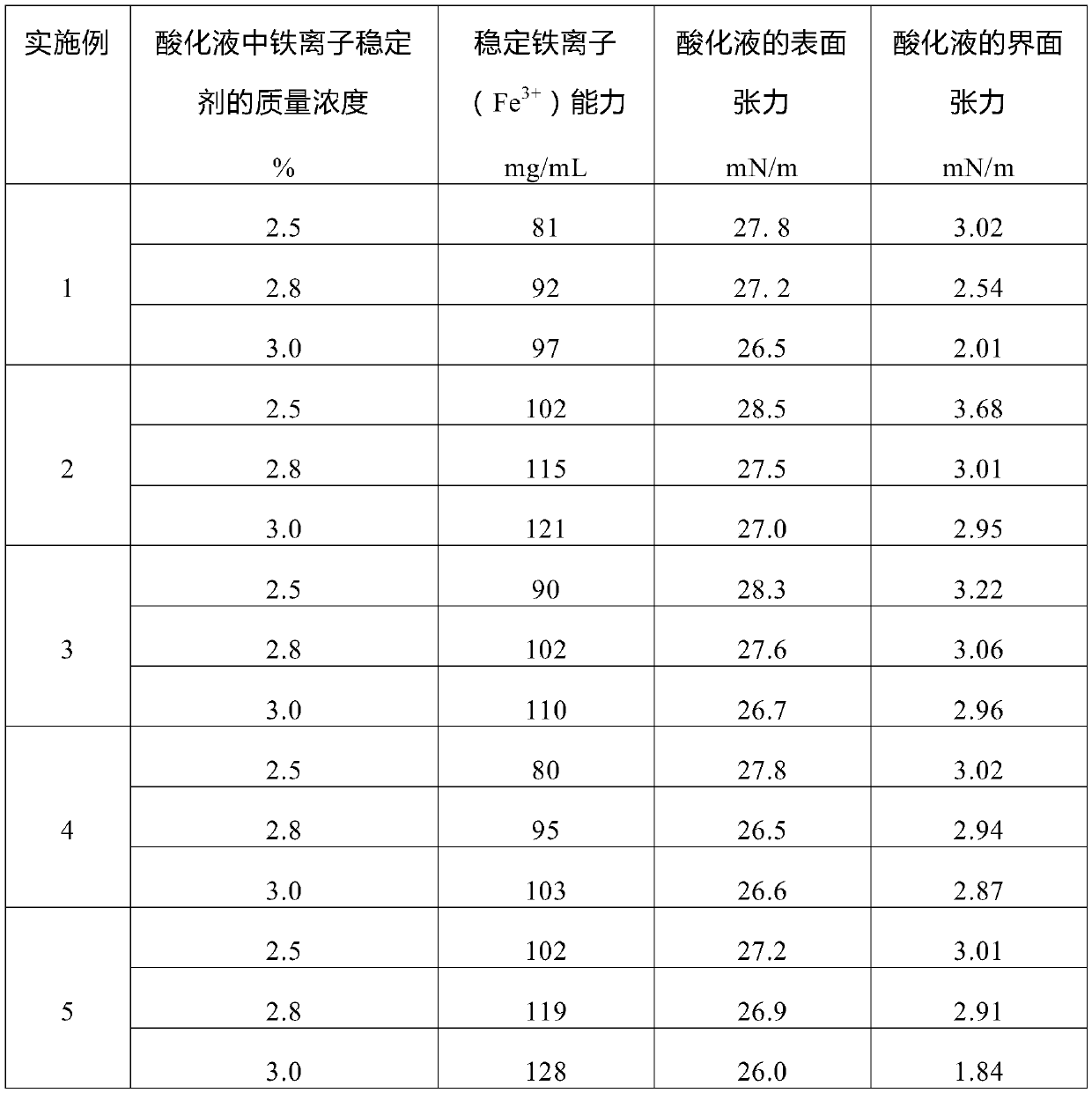

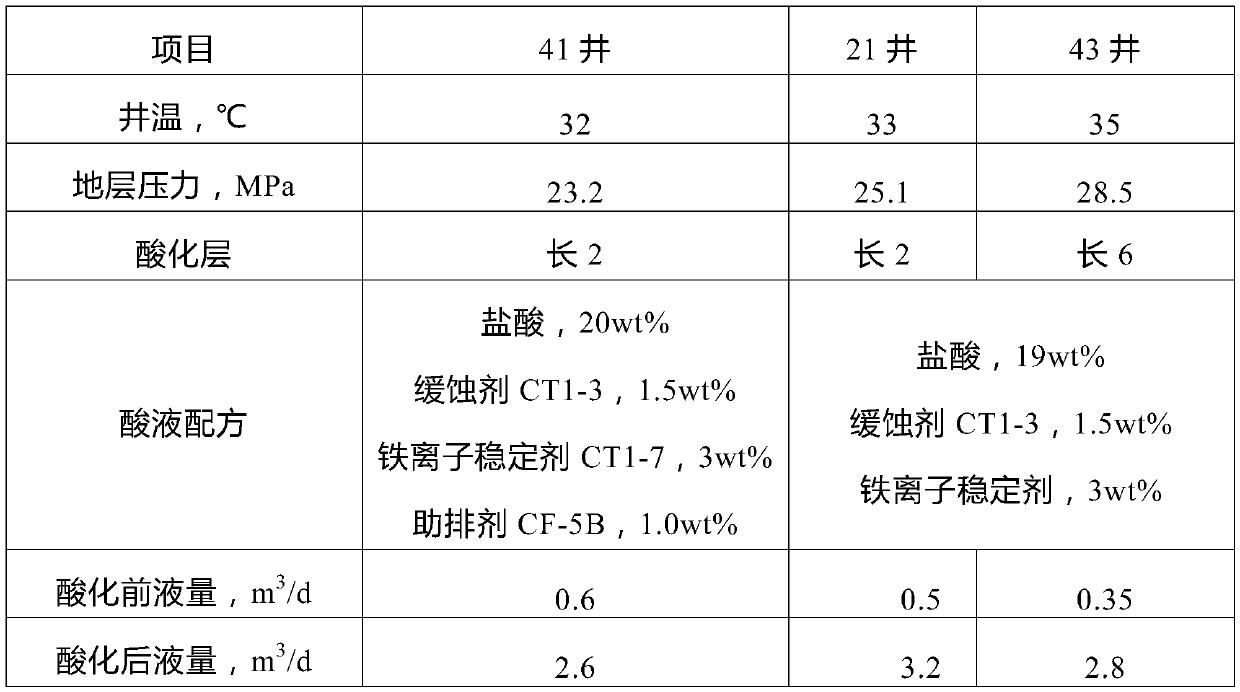

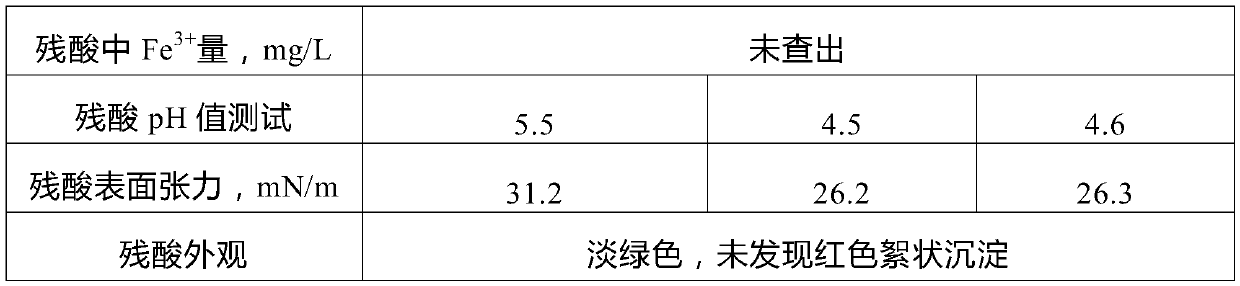

Examples

Embodiment 1

[0022] The preparation method of the multifunctional acidification iron ion stabilizer of the present embodiment comprises the following steps:

[0023] Step 1, placing 37g of industrial hydrochloric acid with a mass concentration of 30% in a reaction vessel with a reflux condenser, opening the reflux condenser to condense the industrial hydrochloric acid, and under stirring conditions at a temperature of 15°C, to the 8g of industrial hydrazine hydrate with a mass concentration of 40% was added dropwise to the reaction vessel for 30 minutes, and after stirring and reacting for 30 minutes, 48g of water was added to the reactor and stirred evenly to obtain solution A;

[0024] Step 2, industrial citric acid, emulsifier OP-10 and Virahol are dissolved in water to obtain solution B; the mass concentration of citric acid in the solution B is 5%, and the mass concentration of emulsifier OP-10 is 20% , the mass concentration of isopropanol is 15%;

[0025] Step 3. At room temperatur...

Embodiment 2

[0027] The preparation method of the multifunctional acidification iron ion stabilizer of the present embodiment comprises the following steps:

[0028] Step 1, 50g mass concentration is that the industrial hydrochloric acid of 30% is placed in the reaction vessel that has reflux condenser, open reflux condenser and described industrial hydrochloric acid is condensed, under the stirring condition that temperature is 10 ℃, to described 15g of industrial hydrazine hydrate with a mass concentration of 40% was added dropwise to the reaction vessel for 40 minutes, stirred and reacted for 60 minutes, and then 72g of water was added to the reactor, and stirred evenly to obtain solution A;

[0029] Step 2, industrial citric acid, emulsifier OP-10 and Virahol are dissolved in water to obtain solution B; the mass concentration of citric acid in the solution B is 10%, and the mass concentration of emulsifier OP-10 is 10% , the mass concentration of isopropanol is 25%;

[0030] Step 3. A...

Embodiment 3

[0032] The preparation method of the multifunctional acidification iron ion stabilizer of the present embodiment comprises the following steps:

[0033] Step 1, placing 48g of industrial hydrochloric acid with a mass concentration of 31% in a reaction vessel with a reflux condenser, opening the reflux condenser to condense the industrial hydrochloric acid, and under stirring conditions at a temperature of 20°C, to the 12g of industrial hydrazine hydrate with a mass concentration of 40% was added dropwise to the reaction vessel, and the dropping time was 35min. After stirring and reacting for 20min, 60g of water was added to the reactor, and the mixture was evenly stirred to obtain solution A;

[0034] Step 2, industrial citric acid, emulsifier OP-10 and Virahol are dissolved in water to obtain solution B; the mass concentration of citric acid in the solution B is 8%, and the mass concentration of emulsifier OP-10 is 15% , the mass concentration of isopropanol is 20%;

[0035]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com