A Coal Gas Freezing Sampler for Air Drilling

A sampler and air technology, which is applied in the preparation of test samples, earthwork drilling, wellbore/well components, etc., can solve the problems of cumbersome operation process and long coal seam core sampling time, and achieves simple operation and reduction of coal gas. Amount of loss, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

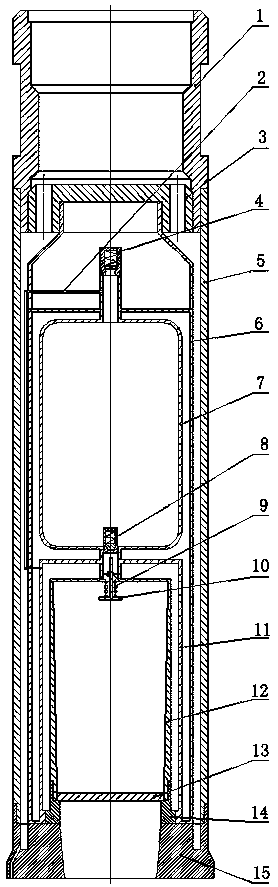

[0017] Such as figure 1 As shown, the present invention includes a vacuum insulation layer formed by welding and closing the inner wall of the shell 6, the inner tank 7 and the cooling jacket 11, the liquid nitrogen storage chamber formed by the inner cavity of the inner tank 7, and the inner wall of the cooling jacket 11 and the conical core tube 12. The freezer chamber formed by the outer wall and the end cover 14, and the thermal insulation sampling chamber formed by the inner cavity of the conical core pipe 12; the upper joint 3 of the sampler is sealed on the top port of the shell 6, and the lower port of the upper joint 1 of the drill pipe is threaded on the sampler On the upper joint 3, the drill pipe 5 is sheathed on the periphery of the outer shell 6, and the upper end of the drill pipe 5 is threaded to the lower part of the upper joint 1 of the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com