Comprehensive analysis method based on multiple thermal protection materials in one flight

A thermal protection material and comprehensive analysis technology, applied in the field of aircraft, can solve the problems such as the thermal environment of heat-resistant materials and the degree of refinement of heat-resistant design are greatly affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

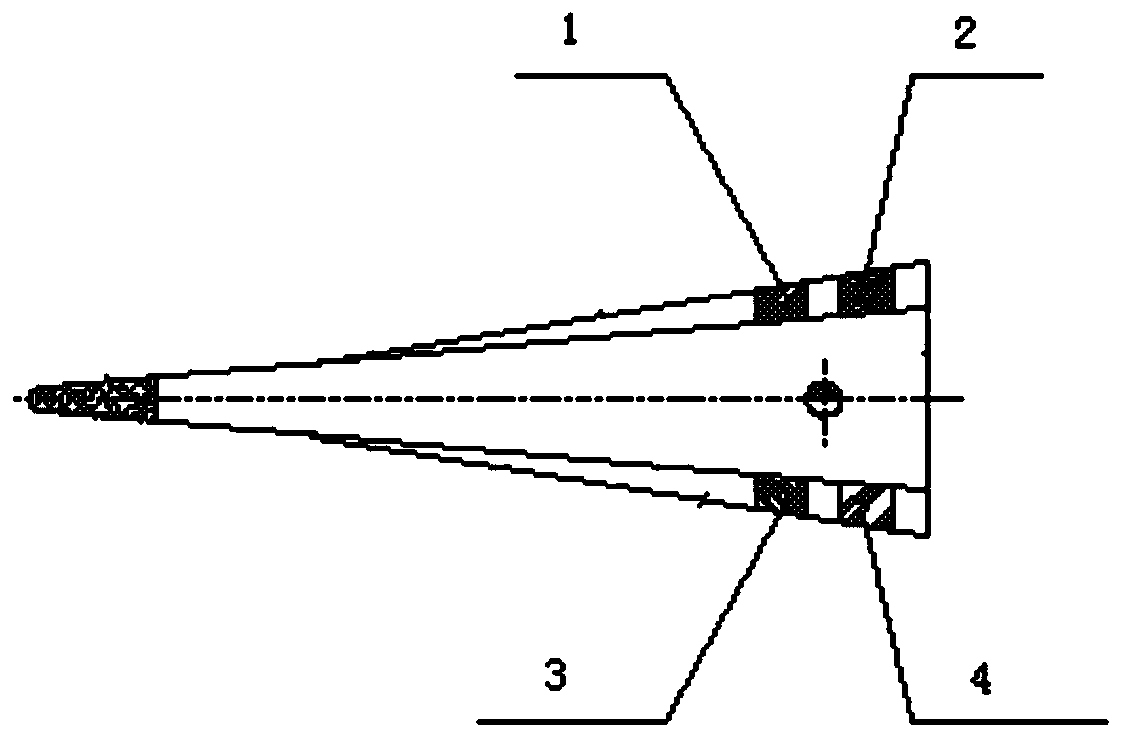

[0024] figure 1 is a schematic diagram of the wing leading edge of the present invention. combine figure 1 As shown, the present invention provides a comprehensive analysis method based on a flight of multiple thermal protection materials, the method may further comprise the steps:

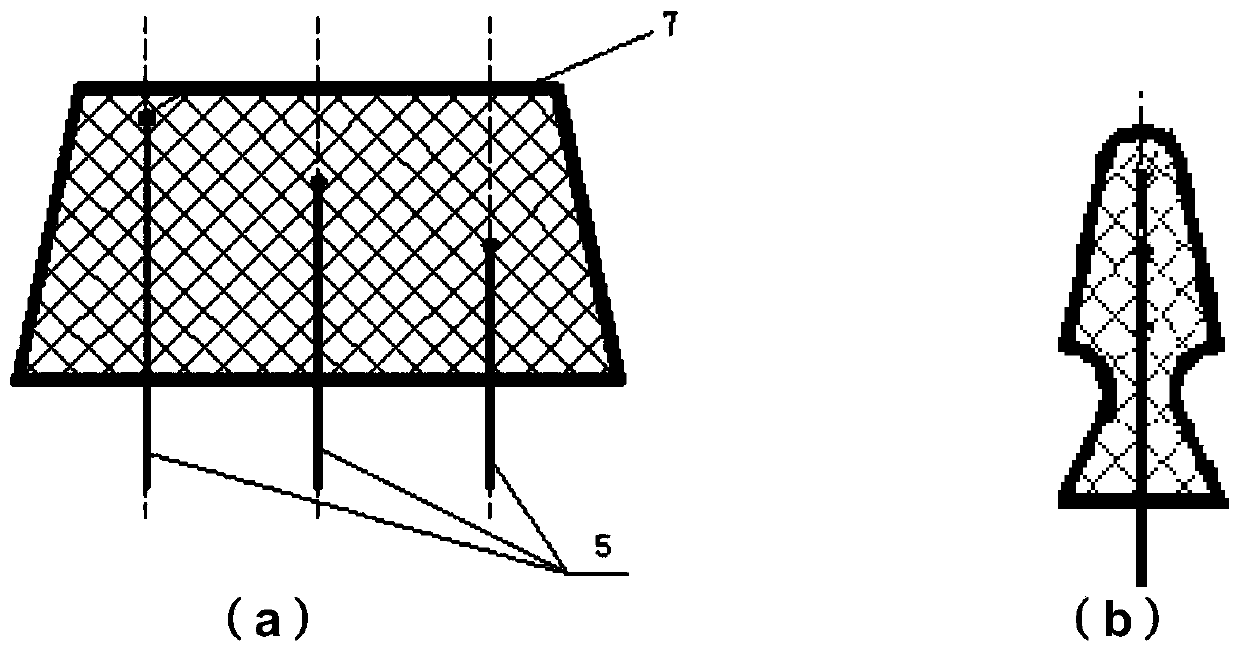

[0025] Step 1: Open the first groove 1 and the second groove 2 on the leading edge of the first wing of the aircraft, and install ultra-high temperature ceramic materials on the first groove 1, and install the first C on the second groove 2 / SiC material, open the third groove 3 and the fourth groove 4 on the leading edge of the second wing of the aircraft, and install the anti-oxidation carbon / carbon material on the third groove 3, install on the fourth groove 4 A second C / SiC material. specific, figure 1 The upper part is the leading edge of the first wing, and the lower part is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com