Self-locking type fastening wire clamp

A fastening and wire clip technology, applied in the direction of clamping/spring connection, electrical components, coupling devices, etc., can solve the problems of difficulty in ensuring the firmness of cable ends, time-consuming and laborious, and randomness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A self-locking fastening clamp of the present invention will be further described below in conjunction with the accompanying drawings:

[0023] It should be noted that the terms "upper", "lower", "front", "rear" and similar expressions used in this specification are only for the purpose of illustration, and are determined according to the actual situation in the embodiment.

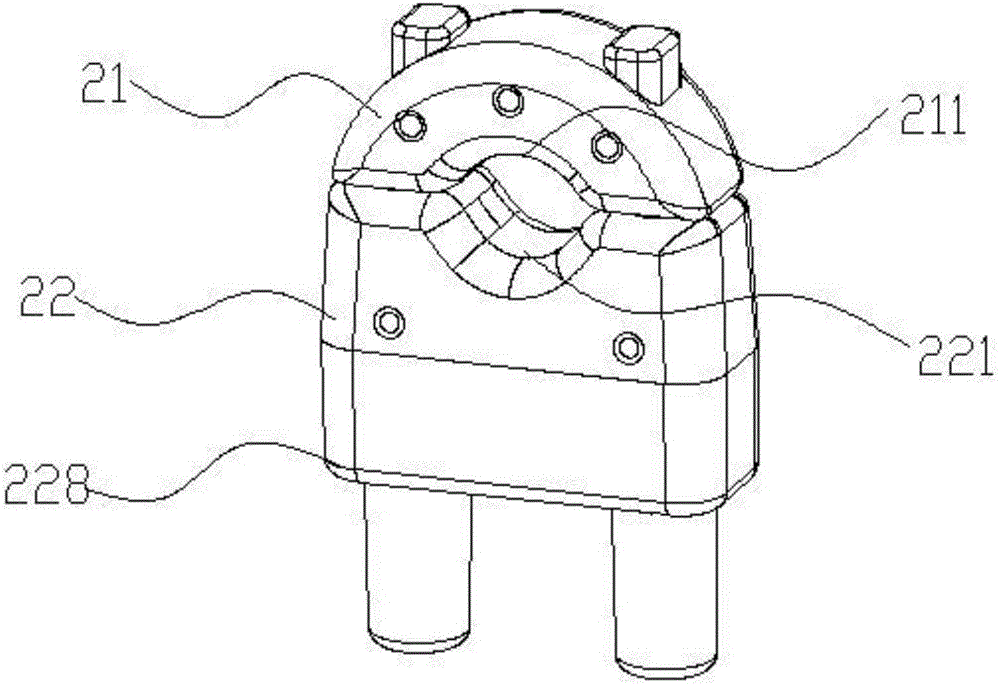

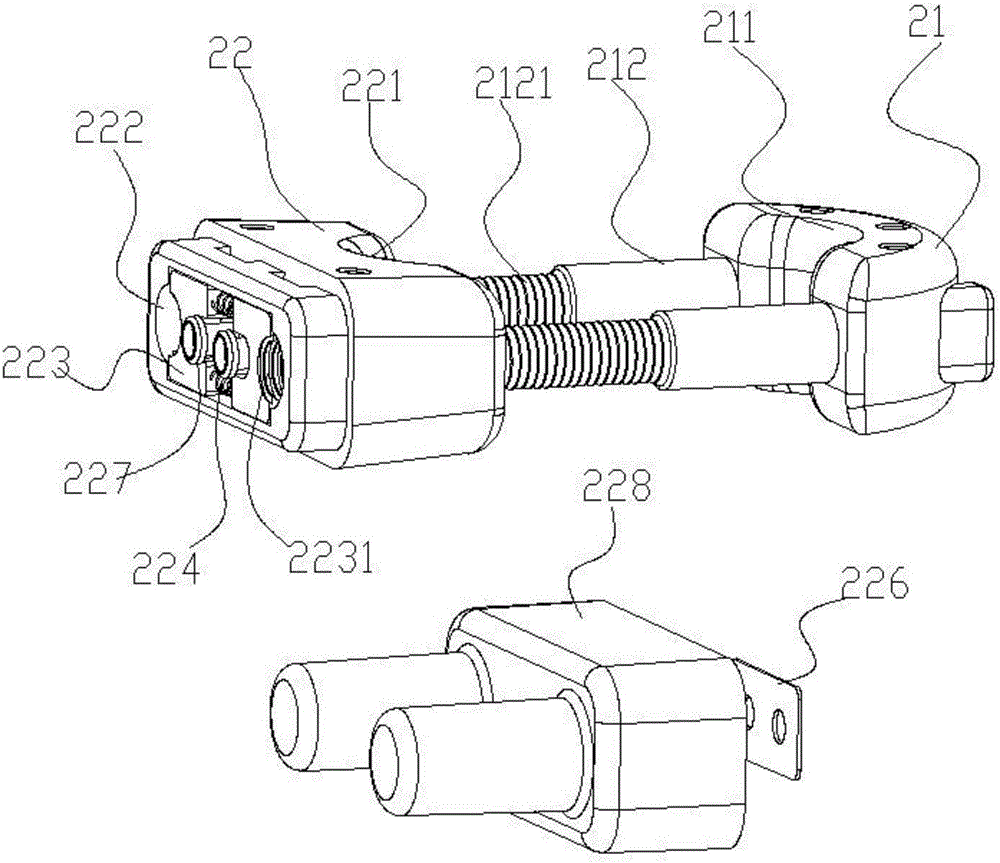

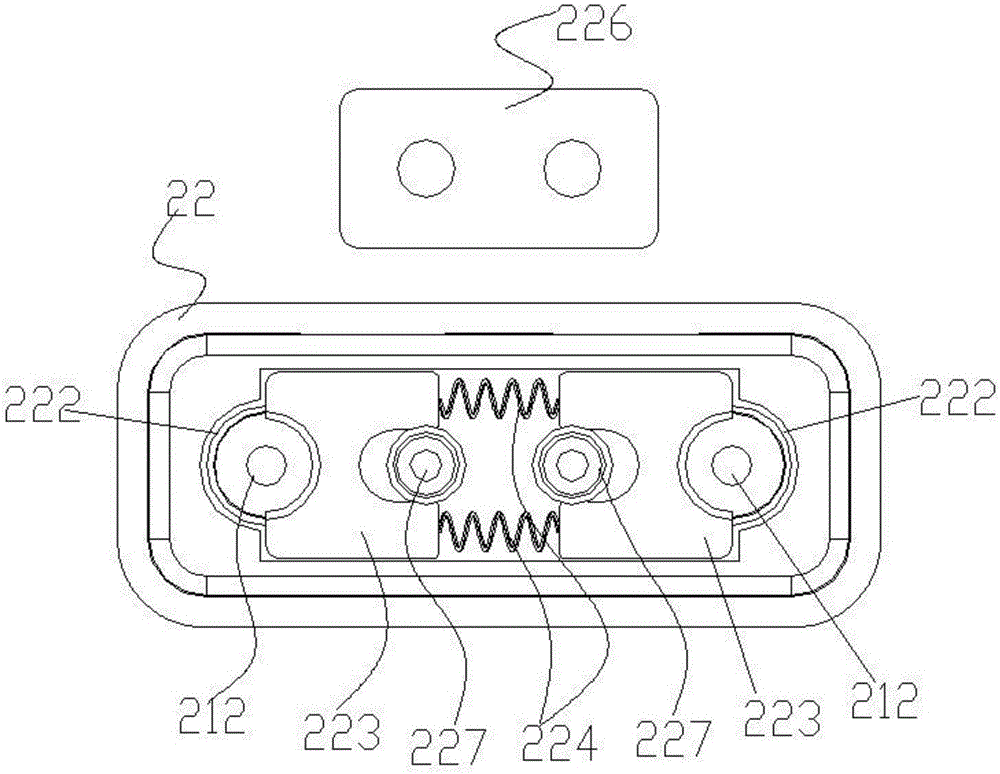

[0024] Such as Figure 1-3 As shown, a self-locking fastening clip includes a U-shaped male clip 21 and a female clip 22, the U-shaped male clip 21 and the female clip 22 are independent of each other, and the bend of the U-shaped male clip 21 is the first The clamping part 211, the front of the female clamp 22 is provided with a corresponding second clamping part 221, the first clamping part 211 and the second clamping part 221 can cooperate to clamp the cable, the two sides of the U-shaped male clamp 21 are The locking rod 212, the two sides of the second clamping part 221 on the female clip 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com