Board taking device and board taking method

A technology of board taking device and control device, which is applied in the direction of measuring device, optical device, circuit board tool positioning, etc., can solve the problems of board bending or warping deformation, damage to board circuit structure, board damage, etc. Achieve the effect of avoiding bending or warping deformation, high precision and maintaining force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

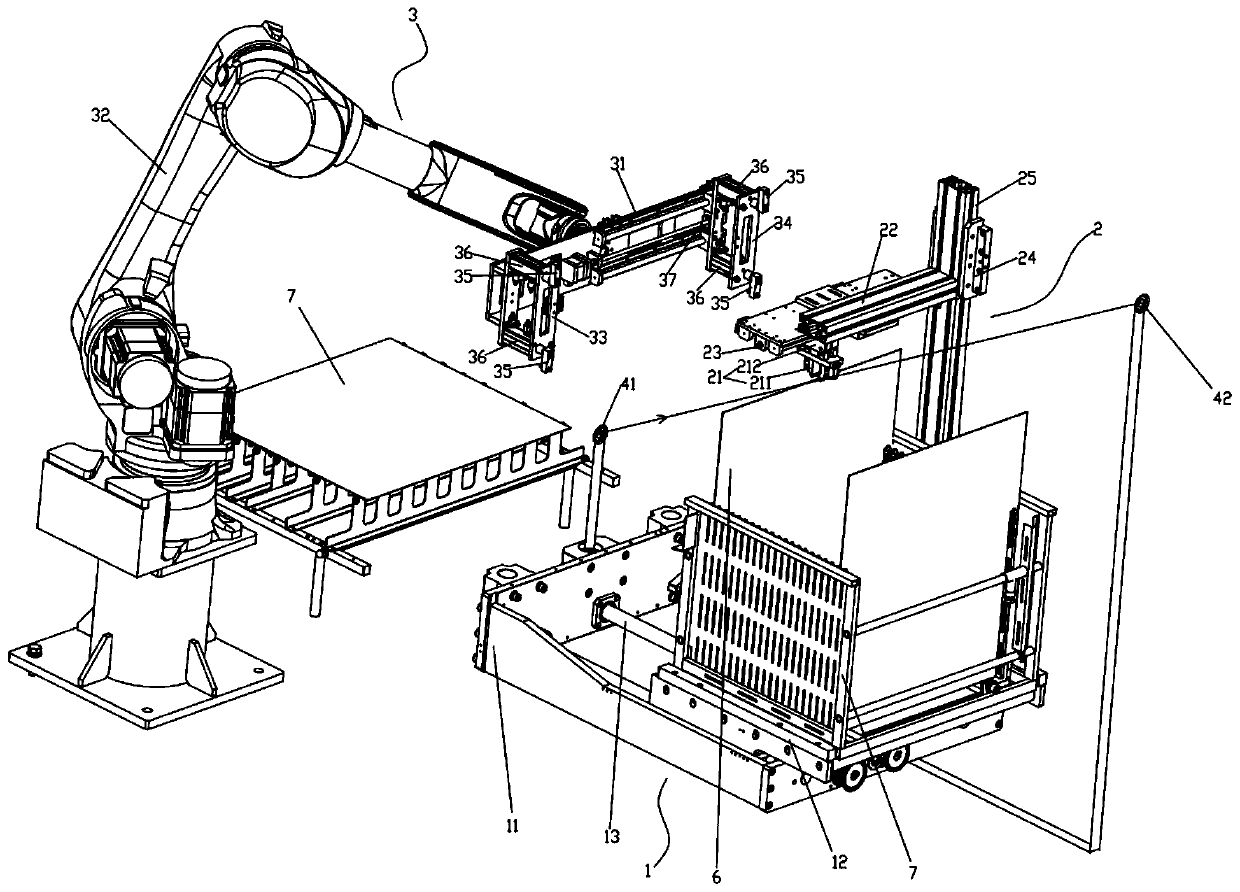

[0027] Such as figure 1 Shown, a kind of plate taking device comprises frame (frame is attached figure 1 not shown in ), the frame is provided with: a plate frame transfer mechanism 1 for moving the plate frame 5 along the X-axis direction, and a square plate to be picked up 6 inserted vertically in the plate frame 5 Grasp and lift along the Z-axis direction to the plate lifting mechanism 2 that moves out the plate frame 5, and is used to balance grab the plate 6 that lifts the plate frame 5 and move it to the plate placing mechanism that is placed flat on the plate position 7 3, and the laser photoelectric sensor and control device, the laser photoelectric sensor includes a laser emitter 41 and a laser receiver 42, the laser emitter 41 is fixedly arranged on the front side of the plate frame 5 and its height is lower than the upper edge of the plate to be taken 6, The laser receiver 42 is fixedly arranged on the rear side of the plate frame 5 and is higher than the upper edg...

Embodiment 2

[0042] On the basis of the technical solution of embodiment 1, further improvement has been carried out:

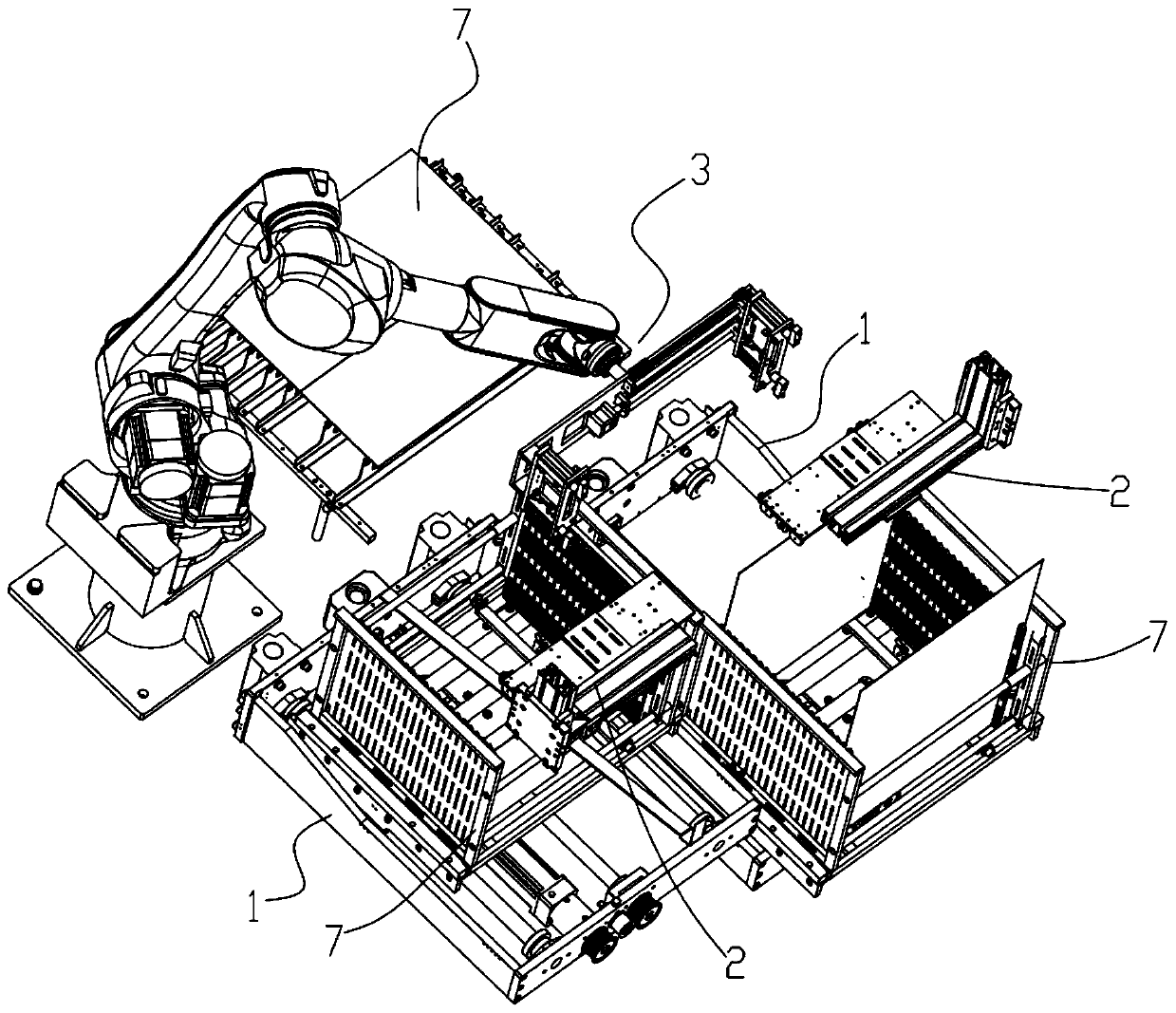

[0043] Such as figure 2 As shown, the plate taking device includes two frame transfer mechanisms 1, each frame transfer mechanism 1 is arranged side by side, and each frame 5 transfer mechanism is respectively provided with a laser photoelectric sensor and a plate lifting mechanism 2, so that The board releasing mechanism 3 can alternately move and turn over the boards lifted up in the two board frames 5 to further improve the board releasing efficiency. figure 2 In order not to block other structures, the laser photoelectric sensor and some supporting structures in this embodiment are not shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com