Motor driving circuit, motor driving method and electronic equipment

A motor drive and circuit technology, applied in the direction of excitation or armature current control, which can solve the problems of inability to exert the transient performance of the motor and small driving voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

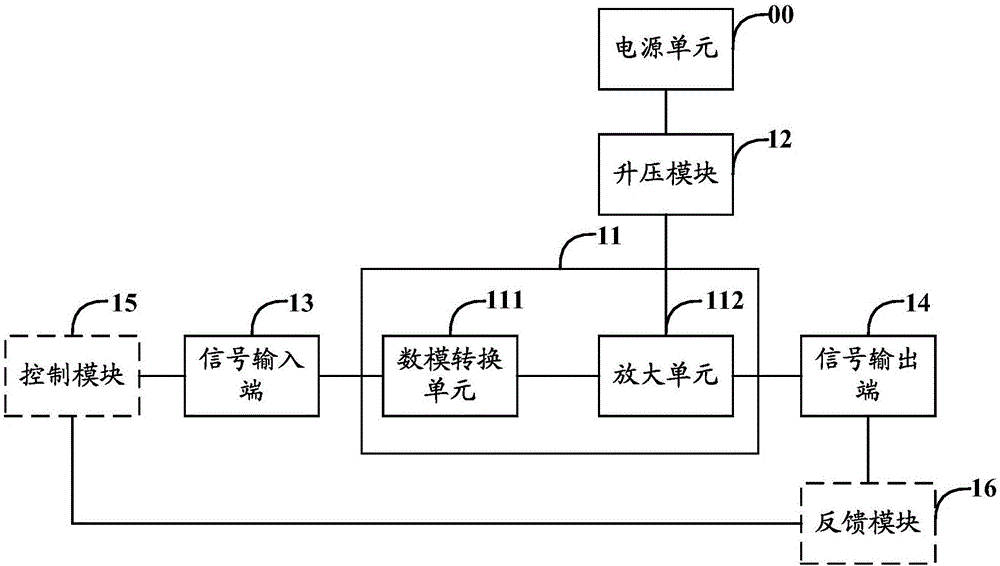

[0025] In order to solve the problems existing in the existing motor driving circuit that the provided driving voltage is small and the transient performance of the motor cannot be utilized, an embodiment of the present invention provides a motor driving circuit, which can be set in a corresponding Electronic devices, such as mobile phones, tablet computers, smart watches and other electronic devices, such as figure 1 As shown, it is a schematic structural diagram of the motor drive circuit described in Embodiment 1 of the present invention. Specifically, by figure 1 It can be seen that the motor drive circuit may include a drive module 11, a boost module 12, and a signal input terminal 13 and a signal output terminal 14 connected to the drive module 11, wherein the drive module 11 is electrically connected to the power supply unit 00, The drive module 11 may include a digital-to-analog conversion unit 111 and an amplification unit 112;

[0026] The digital-to-analog convers...

Embodiment 2

[0059] Based on the same inventive concept as that of Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a motor driving method, such as Image 6 As shown, it is a schematic flowchart of the motor driving method described in the embodiment of the present invention. Specifically, by Image 6 It can be seen that the motor driving method described in the embodiment of the present invention may include:

[0060] Step 601: Receive a digital audio signal for driving the motor, and convert the digital audio signal into an analog signal;

[0061] Step 602: Raise the input voltage provided by the power supply, and amplify the analog signal based on the raised input voltage;

[0062] Step 603: Send the amplified analog signal to the motor.

[0063] That is to say, in the embodiment of the present invention, the digital audio signal for driving the motor can be received, and the digital audio signal can be converted into an analog signal; the input v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com