Engine oil bottle capable of pouring engine oil out quantitatively

An oil and bottle technology, applied in the direction of bottles, internal accessories, etc., can solve the problem of easy contamination of remaining oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

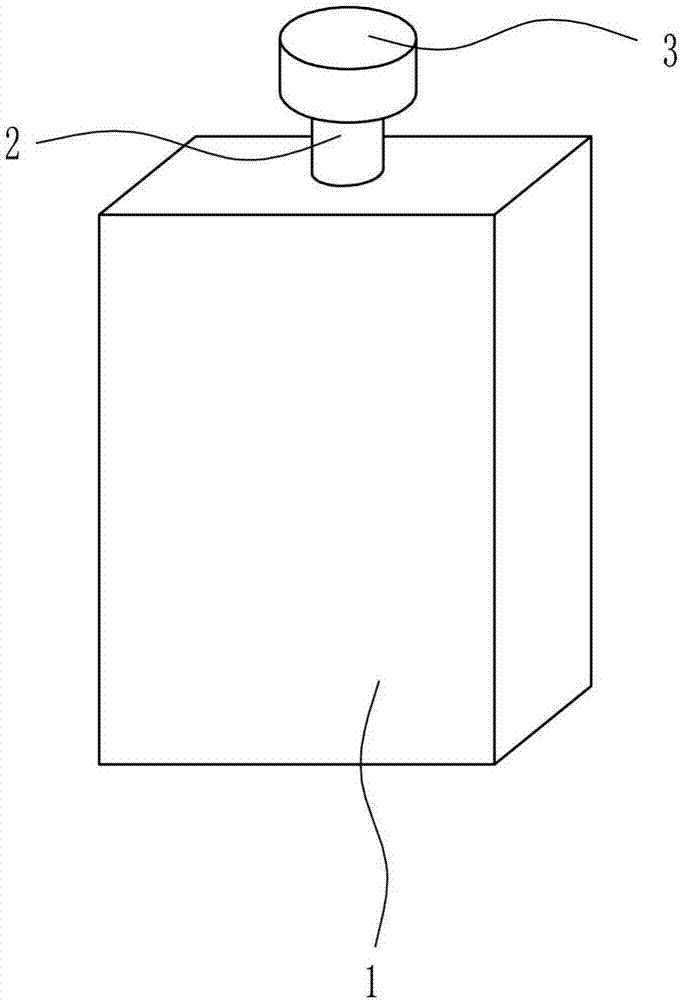

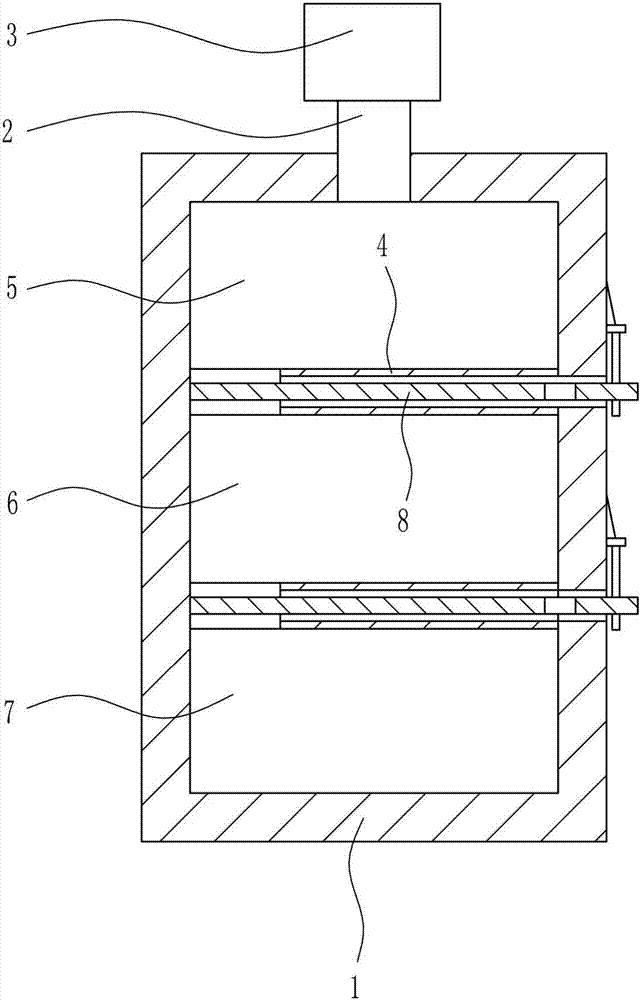

[0026] A kind of engine oil bottle that can quantitatively pour out engine oil, such as Figure 1-5 As shown, it includes a bottle body 1, a discharge pipe 2 and a bottle cap 3. The top center of the bottle body 1 is provided with a discharge pipe 2, and the upper part of the discharge pipe 2 is connected with a bottle cap 3 through a threaded connection. Two partitions 4 are provided, and the partition 4 divides the bottle body 1 into three spaces of equal size. From top to bottom, there are A zone 5, B zone 6 and C zone 7. Inside the divider 4, there are Discharge device 8.

Embodiment 2

[0028] A kind of engine oil bottle that can quantitatively pour out engine oil, such as Figure 1-5 As shown, it includes a bottle body 1, a discharge pipe 2 and a bottle cap 3. The top center of the bottle body 1 is provided with a discharge pipe 2, and the upper part of the discharge pipe 2 is connected with a bottle cap 3 through a threaded connection. Two partitions 4 are provided, and the partition 4 divides the bottle body 1 into three spaces of equal size. From top to bottom, there are A zone 5, B zone 6 and C zone 7. Inside the divider 4, there are Discharge device 8.

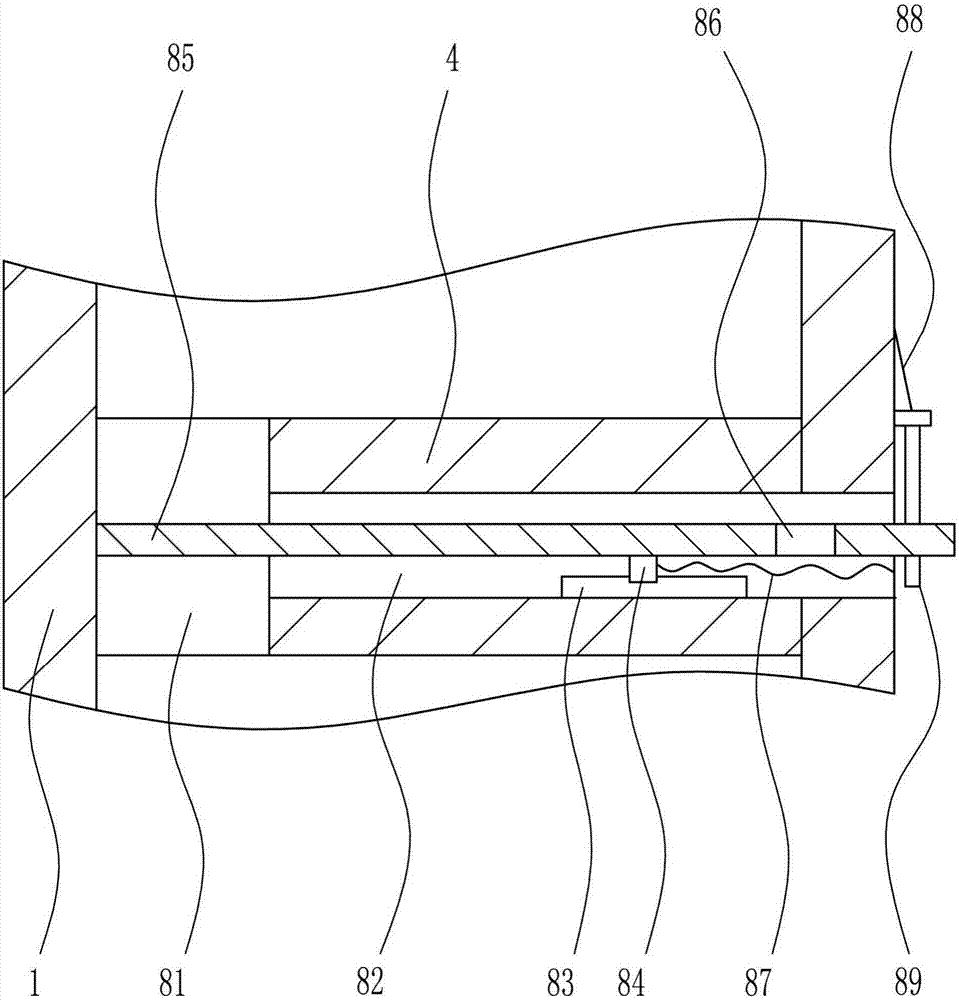

[0029] The discharge device 8 includes a slide rail 83, a slide block 84, a baffle plate 85, a spring 87, a backguy 88 and a plug 89; Cavity 82, the inner bottom of the cavity 82 is provided with a slide rail 83, the top of the slide rail 83 is slidably connected with a slider 84, the top of the slider 84 is provided with a baffle 85, and the left side of the baffle 85 is in contact with the inner left...

Embodiment 3

[0031] A kind of engine oil bottle that can quantitatively pour out engine oil, such as Figure 1-5 As shown, it includes a bottle body 1, a discharge pipe 2 and a bottle cap 3. The top center of the bottle body 1 is provided with a discharge pipe 2, and the upper part of the discharge pipe 2 is connected with a bottle cap 3 through a threaded connection. Two partitions 4 are provided, and the partition 4 divides the bottle body 1 into three spaces of equal size. From top to bottom, there are A zone 5, B zone 6 and C zone 7. Inside the divider 4, there are Discharge device 8.

[0032] The discharge device 8 includes a slide rail 83, a slide block 84, a baffle plate 85, a spring 87, a backguy 88 and a plug 89; Cavity 82, the inner bottom of the cavity 82 is provided with a slide rail 83, the top of the slide rail 83 is slidably connected with a slider 84, the top of the slider 84 is provided with a baffle 85, and the left side of the baffle 85 is in contact with the inner left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com