Self-clamping and bearing frame for coreless stained paper roll

A technology for bearing frames and paper rolls, applied in the direction of external frames, rigid containers, containers, etc., can solve the problems of coreless flower paper breakage, flower paper bending, and reduce the amount of space occupied by flower paper, so as to achieve low cost and avoid load Concentration, the effect of avoiding the risk of overall bending or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

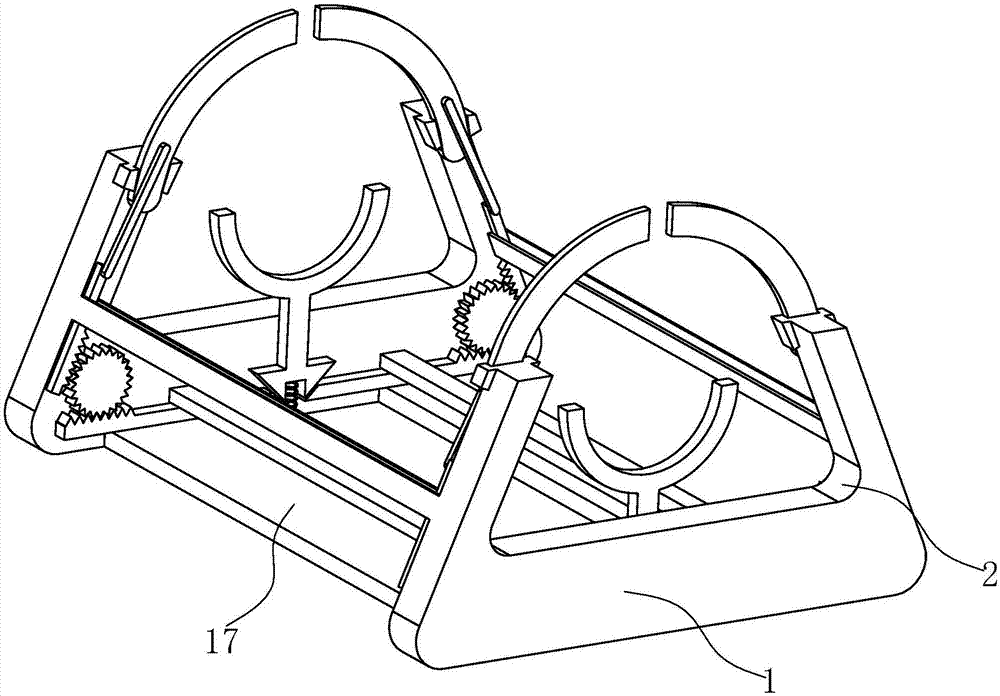

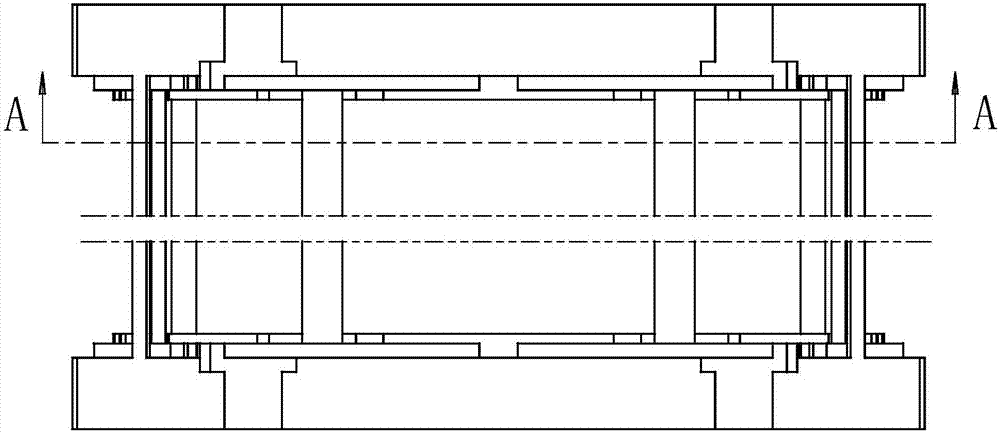

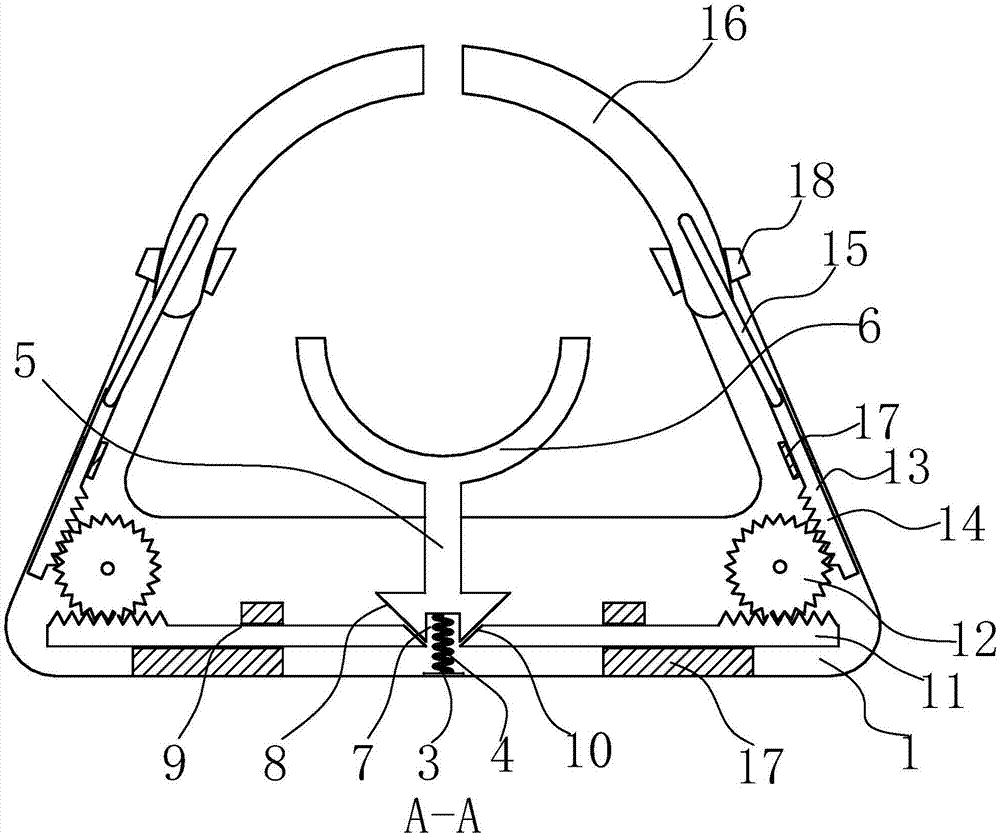

[0020] Such as Figure 1 to Figure 3 As shown, a coreless decal paper roll self-clamping carrier includes two carrier substrates 1 arranged on the front and rear sides respectively. There is a No. 1 opening 2, and the shape of the No. 1 opening 2 is an isosceles trapezoid;

[0021] The carrying substrates 1 are all placed vertically, and the lower side of the middle part of the front end surface of the carrying substrate 1 on the rear side is provided with a blocking piece 3 extending longitudinally forward, and a spring 4 is fixedly installed on the upper end surface of the blocking piece 3. The upper end of the spring 4 is connected with a support bracket 5, the upper end of the support bracket 5 is provided with a downwardly concave arc support surface 6, and the lower end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com