Low pressure air system for alumina production

An alumina and air system technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of abnormal vibration, insufficient flow, and high temperature, and achieve the effects of low energy loss, reduced power consumption and production cost, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

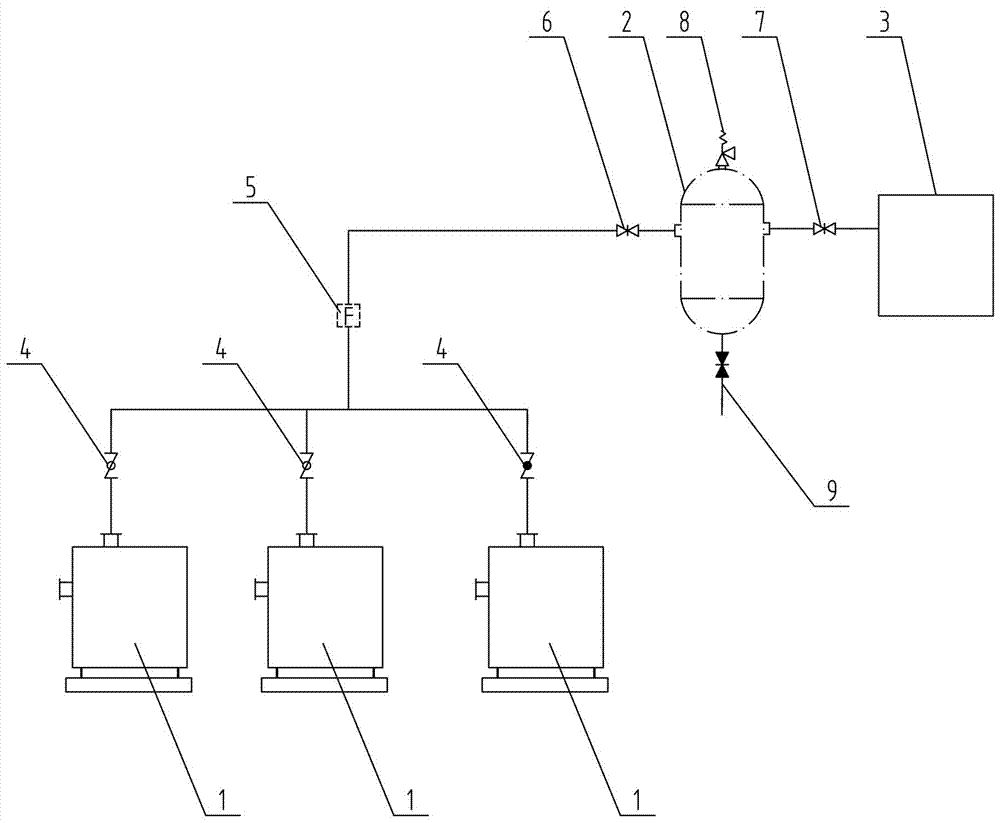

[0019] Such as figure 1 As shown, in the low-pressure wind system for alumina production in the present invention, there are three air suspension centrifugal blowers 1, and the three air suspension centrifugal blowers 1 are connected in parallel. It is directly connected to the gas terminal 3 through a pipeline.

[0020] When the gas end 3 is a vertical disc filter, the air suspension centrifugal blower 1 is stabilized by the compressed air storage tank 2 and then connected to the gas end 3 .

[0021] The outlet of the air suspension centrifugal blower 1 is provided with a fan outlet valve 4 and a flow meter 5 in sequence.

[0022] The inlet end of the compressed air storage tank 2 is provided with a compressed air storage tank inlet valve 6, the outlet end of the compressed air storage tank 2 is provided with a compressed air storage tank outlet valve 7, and the top of the compressed air storage tank 2 is provided with a compressed air storage tank The bottom of the compres...

Embodiment 2

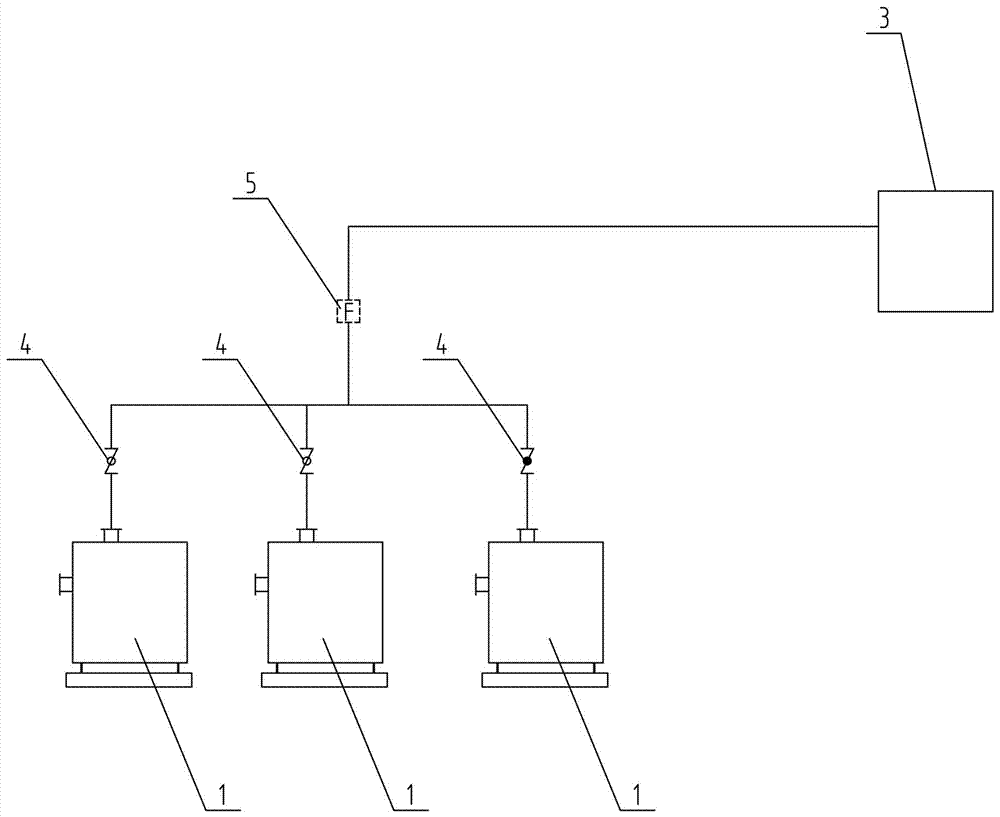

[0024] Such as figure 2 As shown, the low-pressure wind system for alumina production in the present invention includes one air-suspension centrifugal blower 1, which adopts a high-speed direct-connected motor, and the air outlet of the air-suspension centrifugal blower 1 is directly connected to the air terminal 3 through a pipeline.

[0025] The gas terminal 3 is used for the fluidized cooler of the roasting section and the electric dust collection of the roasting section.

[0026] The outlet of the air suspension centrifugal blower 1 is provided with a fan outlet valve 4 and a flow meter 5 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com