Tubular PECVD equipment and method for preparing rear passivation film

A back passivation, tube-type technology, applied in the direction of final product manufacturing, gaseous chemical plating, sustainable manufacturing/processing, etc., can solve the problem of reducing the total time of a single process and the unsatisfactory passivation effect of the back passivation layer , Affecting production capacity improvement and other issues, to achieve the effect of reducing power consumption and production costs, simplifying the gas system, and improving production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

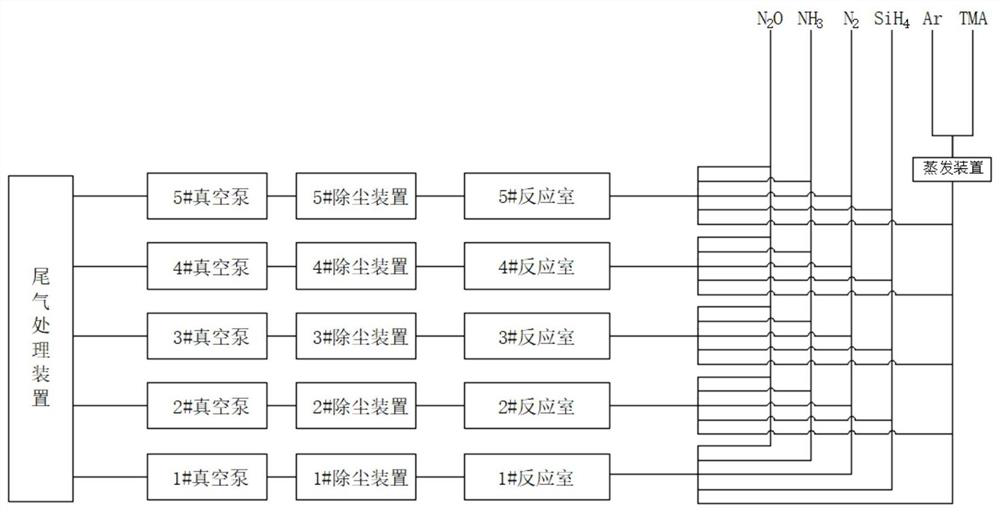

[0034] A tubular PECVD device for preparing a backside passivation film, including a reaction chamber for depositing an AlOx film and four reaction chambers for depositing a SiON film / SiNx film, wherein the gas inlet for the reaction chamber for depositing an AlOx film N 2 O intake pipe, NH 3 Intake manifold, TMA / Ar intake manifold and N 2 Intake pipe; the suction port of the reaction chamber for depositing AlOx film is connected with a vacuum pump; a dust removal device is provided between the reaction chamber for depositing AlOx film and the vacuum pump; the air inlet of the reaction chamber for depositing SiON film / SiNx film Connectivity has N 2 O intake pipe, NH 3 Intake pipe, N 2 Intake pipe and SiH 4 Intake pipe.

[0035] In this embodiment, by setting the reaction chamber for depositing AlOx film and the reaction chamber for depositing SiON film / SiNx film, the deposition process of AlOx film and SiON film / SiNx film is carried out in at least two different reaction...

Embodiment 2

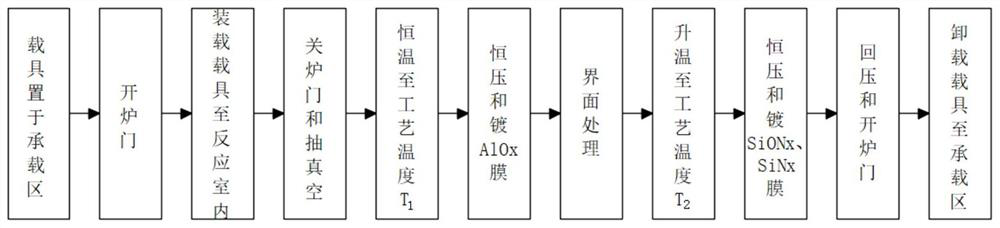

[0043] A method for preparing a back passivation film, adopting the tubular PECVD equipment in embodiment 1 to prepare a back passivation film, comprising the following steps:

[0044] S1: Place the graphite boat carrier filled with slides in the 1# reaction chamber (the reaction chamber used to deposit the AlOx film), vacuumize, and keep the temperature at 300°C.

[0045] S2: After the temperature is stabilized, the process gas (N 2 O, TMA, Ar gas) and keep the pressure in the 1# reaction chamber (reaction chamber for depositing AlOx film) constant at 210Pa, turn on the intermediate frequency power supply, the power supply is 7500W, the temperature is constant at 300°C, N 2 The O flow rate is 3500 sccm, the TMA flow rate is 1.3 mg / min, and the Ar flow rate is 2500 sccm. The AlOx film is deposited on the back of the silicon wafer for 150 s. The AlOx film has a thickness of 18 nm and a refractive index of 1.62.

[0046] S3: evacuate the 1# reaction chamber (reaction chamber fo...

Embodiment 3

[0063] A method for preparing a back passivation film, adopting the tubular PECVD equipment in embodiment 1 to prepare a back passivation film, comprising the following steps:

[0064]S1: Place the graphite boat carrier filled with slides in the 1# reaction chamber (the reaction chamber used to deposit the AlOx film), vacuumize, and keep the temperature at 300°C.

[0065] S2: After the temperature is stabilized, the process gas (N 2 O, TMA, Ar gas) and keep the pressure in the 1# reaction chamber (reaction chamber for depositing AlOx film) constant at 210Pa, turn on the intermediate frequency power supply, the power supply is 7500W, the temperature is constant at 300°C, N 2 The O flow rate is 3500 sccm, the TMA flow rate is 1.3 mg / min, and the Ar flow rate is 2500 sccm. The AlOx film is deposited on the back of the silicon wafer for 150 s. The AlOx film has a thickness of 18 nm and a refractive index of 1.62.

[0066] S3: evacuate the 1# reaction chamber (reaction chamber for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com