Bridge steel box girder production system and bridge steel box girder production method

A production system and steel box girder technology, applied in the direction of gas flame welding equipment, plasma welding equipment, arc welding equipment, etc., can solve the problems of workers' fatigue, work-related accidents, low production efficiency, etc., and achieve the reduction of repair rate and intelligentization High degree, the effect of improving production efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

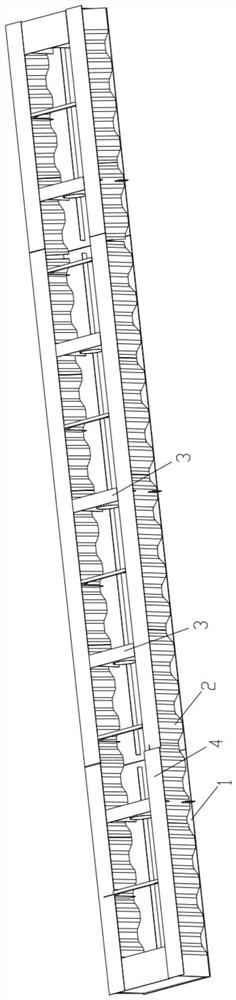

[0033] This embodiment provides a bridge steel box girder production equipment, wherein, such as figure 1 As shown, the bridge steel box girder includes: a bottom plate 1, a corrugated steel web 2 vertically connected to the bottom plate 1 at the top, a connecting plate 4 vertically connected to the bottom of the corrugated steel web 2, and a connecting plate vertically connected to the bottom plate 1 Separator 3: There are two groups of corrugated steel webs 2, and they are arranged in parallel, each partition 3 is located between two groups of corrugated steel webs 2, and each partition 3 is connected to the Web 2 is vertical or nearly vertical.

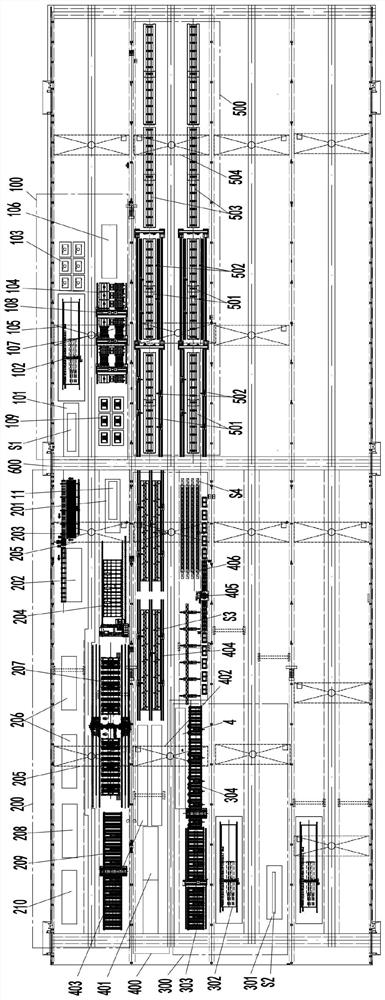

[0034] Such as figure 2 As shown, the bridge steel box girder production system includes:

[0035] A partition unit station 100, which is used to obtain the steel box girder partition 3;

[0036] Base unit station 200, which is used to obtain the steel box girder base 1;

[0037] Connecting plate unit station 300, which is use...

Embodiment 2

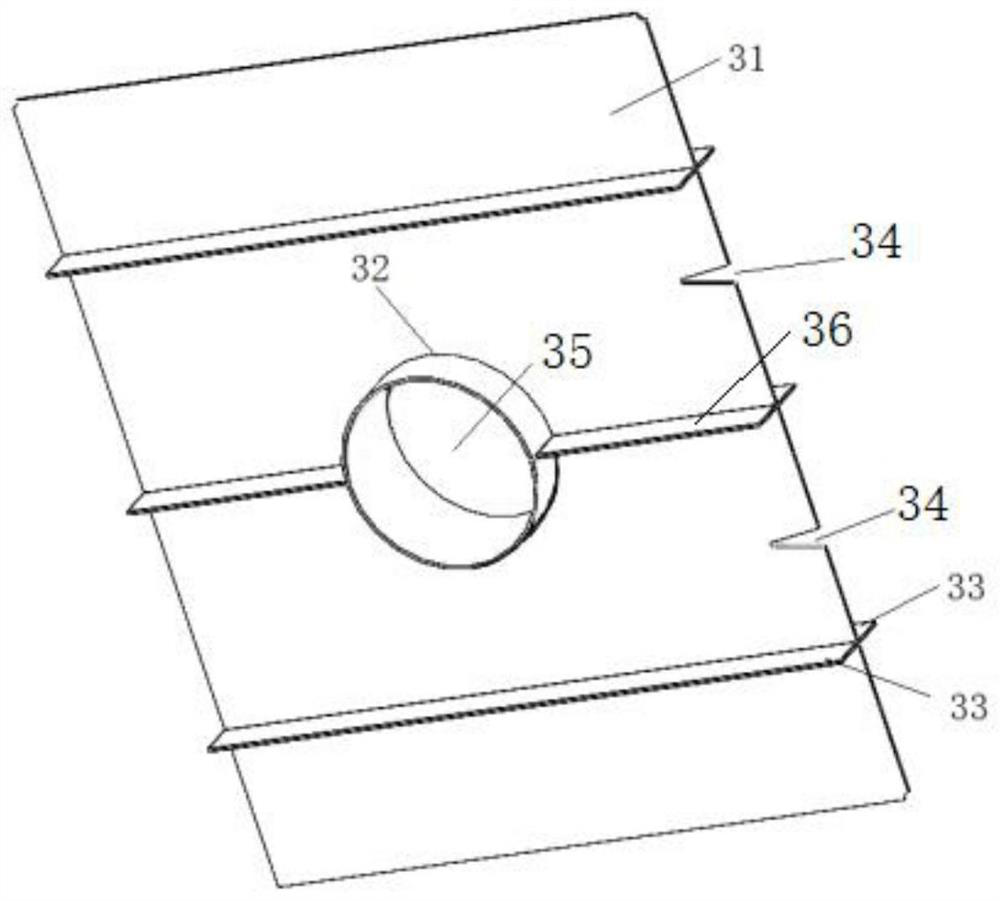

[0077] The difference between this embodiment and embodiment 1 is that, as Figure 7-8 As shown, the top web assembly station 403 includes: a connecting plate support mechanism 43, which is used to support the connecting plate 4, and can drive the moving of the connecting plate 4, so that the two length sides of the connecting plate 4 are in line with the The distance of the horizontal plane is different, thus making the connecting plate 4 inclined relative to the horizontal plane, for example, as Figure 8 As shown, the distance H between the first length side 42 of the connection board 4 and the horizontal plane P is smaller than the distance H' between the second length side 42' and the horizontal plane, thus making the connection board 4 in an inclined state relative to the horizontal plane P; the connection board abutting mechanism 44, which is used to resist a length side (such as the first length side 42) of the connecting plate 4 with a relatively small distance from t...

Embodiment 3

[0093] At present, the welding of the corrugated steel web and the connecting plate is mostly completed by manual welding. However, due to the long length of the weld of the corrugated steel web (the length of the corrugated steel web can reach 30m), the welder needs to work for a long time. , overloaded welding work can be completed, but long-term exposure to the welding environment with loud noise and toxic fumes will cause irreversible damage to the health of employees, and the long training period and insufficient number of qualified welders lead to production capacity that cannot meet the market need. Thus, the present embodiment differs from Embodiment 1 or 2 in that, as Figure 10 As shown, the top web welding station 404 includes:

[0094] The first guide rail 4041, the second guide rail 4042, and the third guide rail 4043 arranged parallel to each other, and the second guide rail 4042 is located between the first guide rail 4041 and the third guide rail 4043; meanwhi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com