Automatic turn-over frame mechanism for sheet metal products

A technology of automatic turning and surface racking, which is applied in the field of sheet metal processing, can solve the problems of poor robot unloading and reclaiming posture, difficulty and heavy workload of on-site debugging, and improve takt time, so as to shorten project delivery time and reduce debugging. Difficulty and commissioning time, the effect of improving production efficiency and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

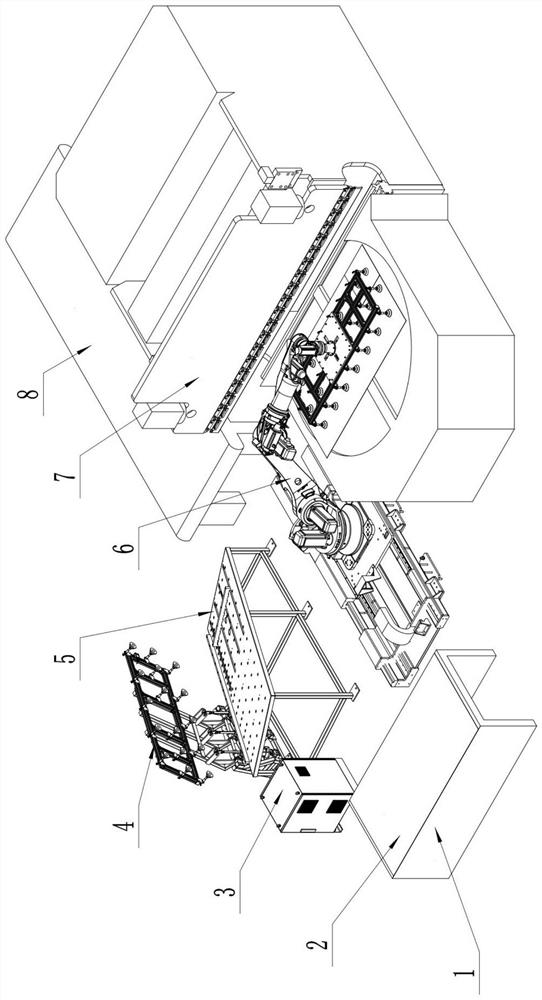

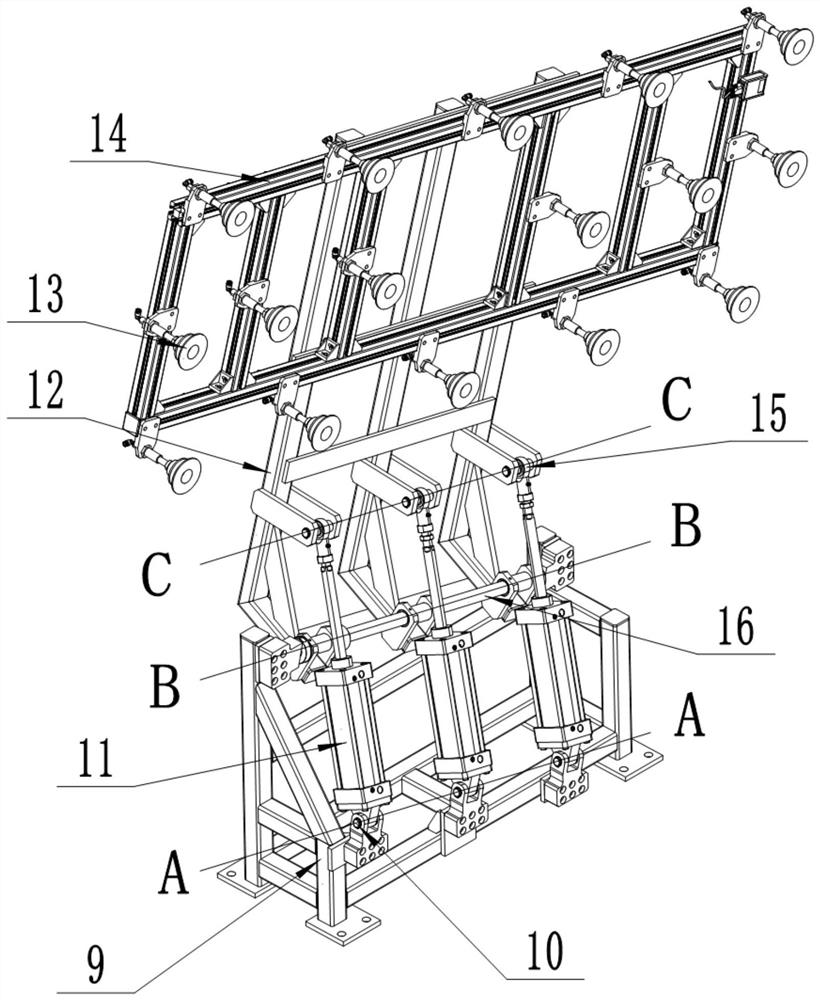

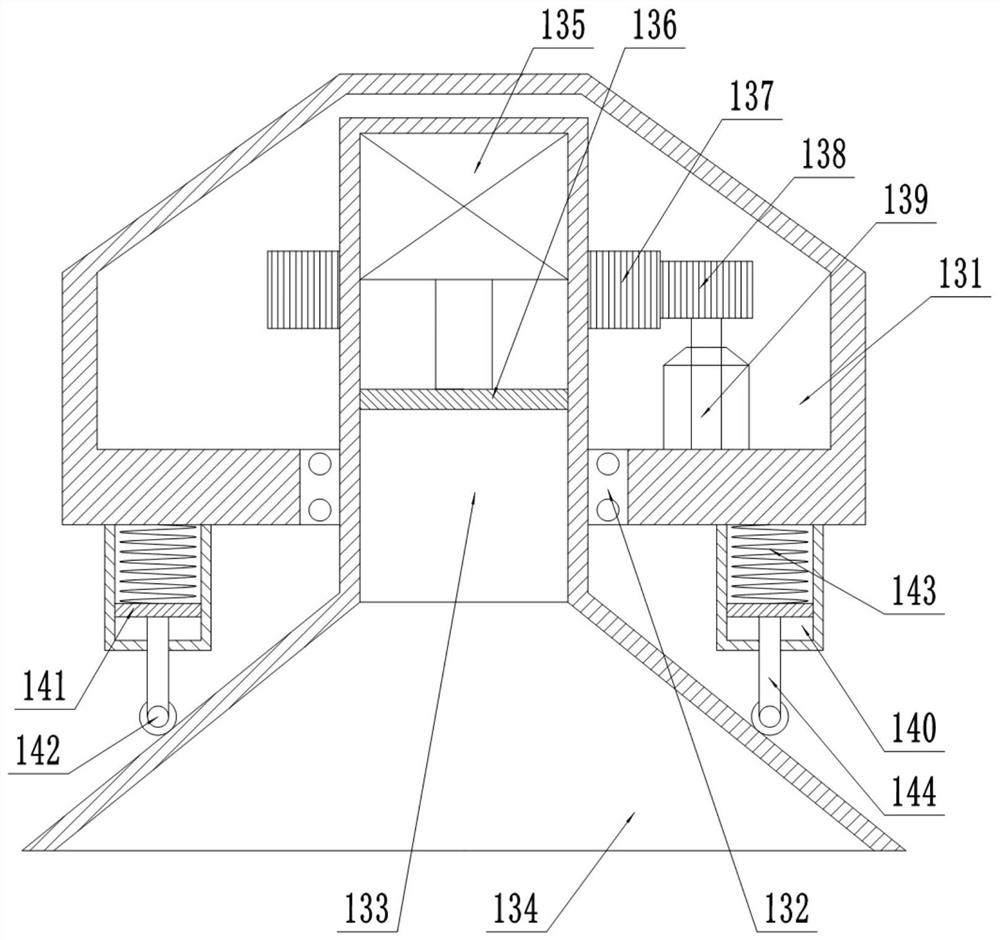

[0022] like figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: an automatic turning frame mechanism for sheet metal products, including a feeding table 1, a sheet metal table 2, a power supply cabinet 3, a turning frame 4, a centering table 5, a mechanical arm 6. The bending device 7 and the conveying line 8; the left side of the mechanical arm 6 is provided with an incoming table 1, and the upper part of the incoming table 1 is provided with a sheet metal table 2; the right side of the mechanical arm 6 is provided with A bending device 7, one side of the bending device 7 is provided with a conveying line 8; the front end of the robotic arm 6 is provided with a centering table 5, and the centering table 5 is provided with a power supply cabinet 3 and a turning surface around it The frame 4; the structure of the turning frame 4 includes: a fixed frame 9, a first rotating shaft 10, an air cylinder 11, a rotating frame 12, a sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com