Needle valve type cold channel silica gel single-KEY mould structure

A technology of needle valve and mold, which is applied in the field of liquid needle valve type cold channel silicone single KEY mold structure, which can solve the problems of uneven peakforce of single KEY load, affecting single KEY dimensional stability, single KEY dimensional instability, etc., to achieve dimensional stability , load balance, load stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

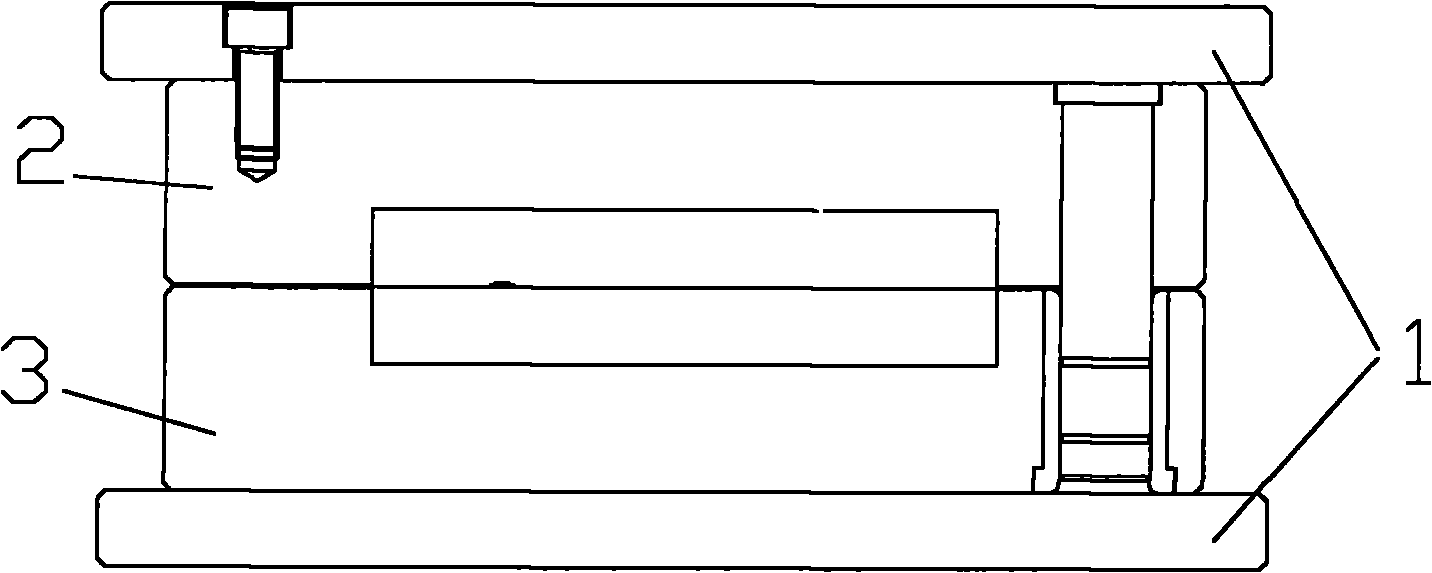

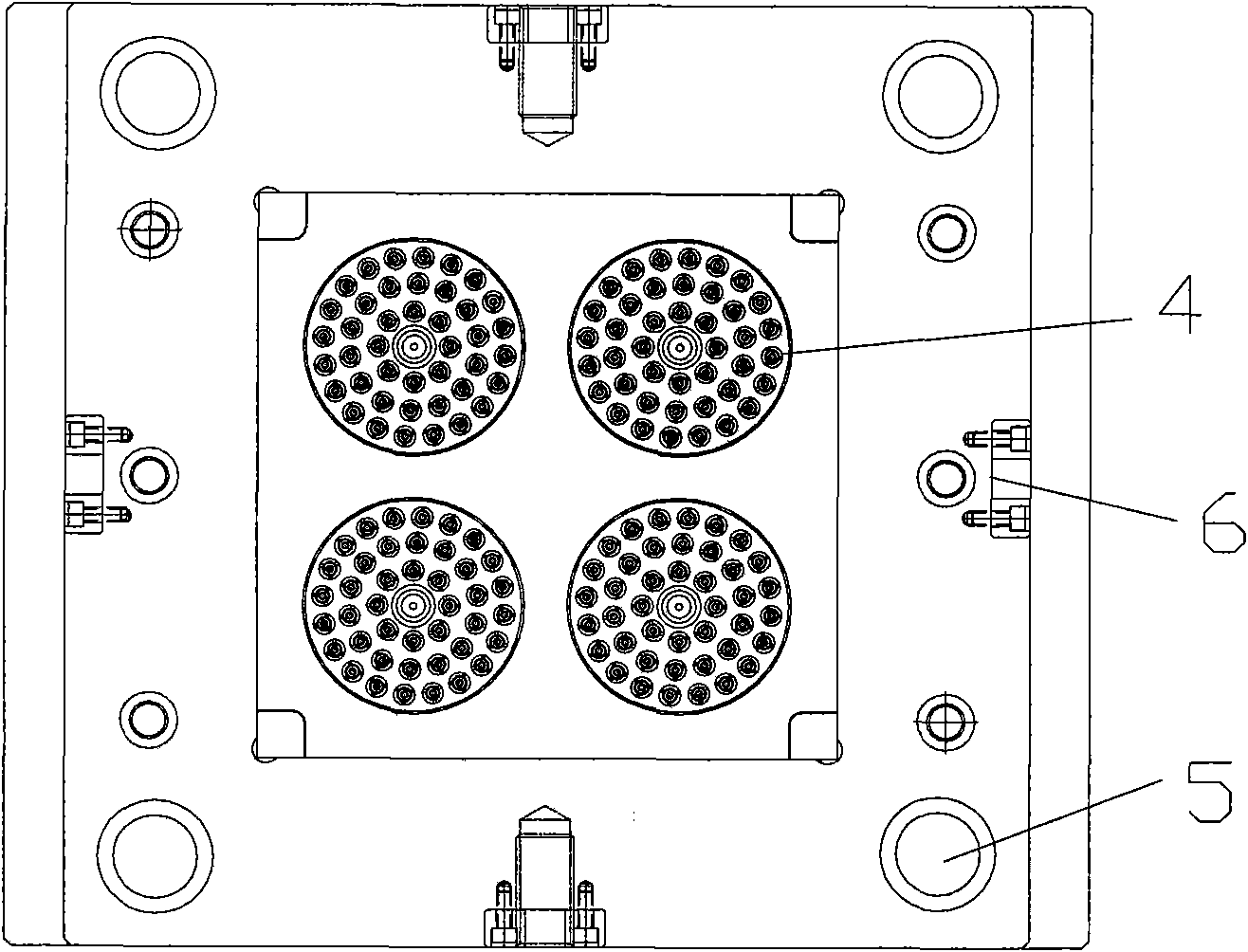

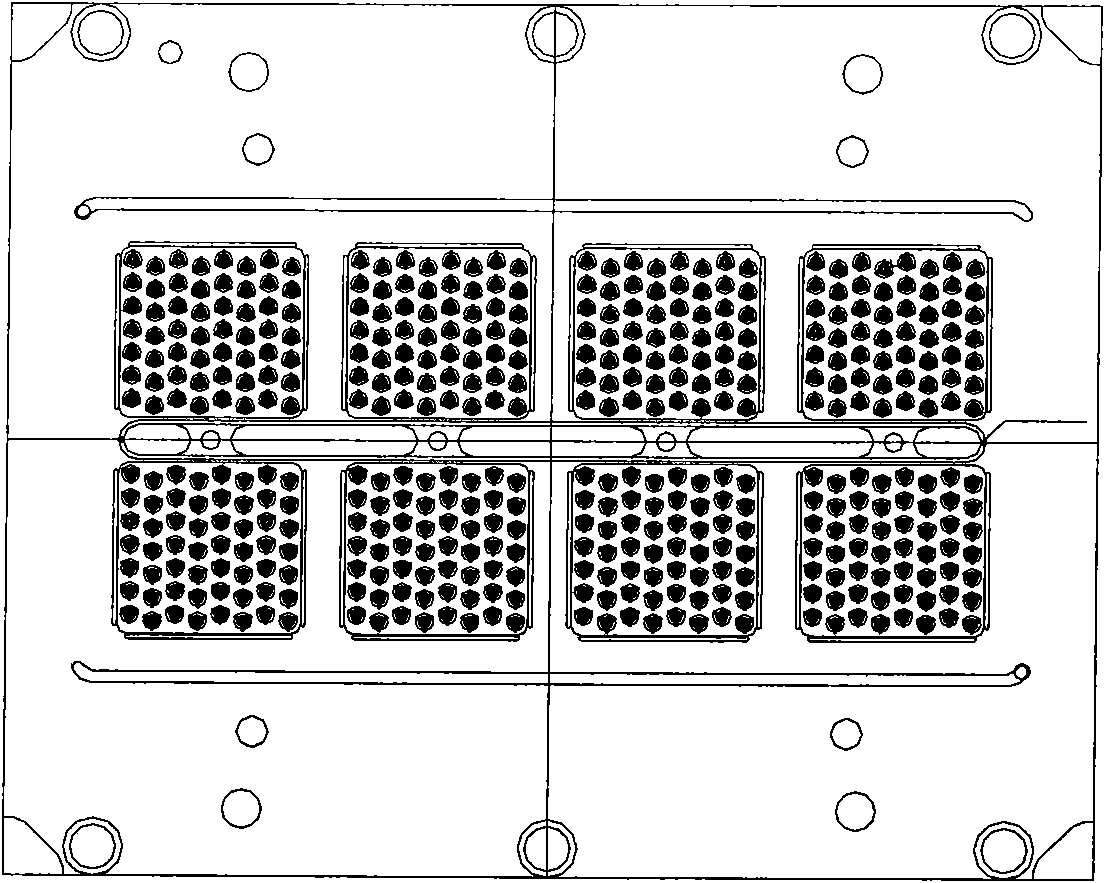

[0013] Such as Figure 1 to Figure 2 As shown, a needle valve type cold channel silicone single KEY mold structure of the present invention is used to form single key products, including a mold base 1, a front mold 2 arranged on the mold base 1, and a front mold 2 opposite to the mold base 1. , the rear mold 3 arranged on the mold blank 1, the cavity 4 of the formed product is arranged between the front mold 2 and the rear mold 3; the mold also includes a guide post 5 and a side lock 6 for positioning, and more Further solve the positioning problem of the traditional mold, and further effectively prevent the movement deviation of the mold during the processing and forming process; a needle valve type injection head (not shown) for liquid injection molding is arranged above the middle of the cavity 4, It can save raw materials, easy to clean, and the molding time is short and the efficiency is high. The mold adopts a plastic mold blank, the mold positioning is accurate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com