Method for Preparing Workstation for Resumption of Spinning Process on Air-Jet Spinning Machine and Air-Jet Spinning Machine for Performing Method

A technology for air-jet spinning machines and workstations, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc. It can solve the problems of uniformity degradation of joint parameters and achieve the effect of uniform joint parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

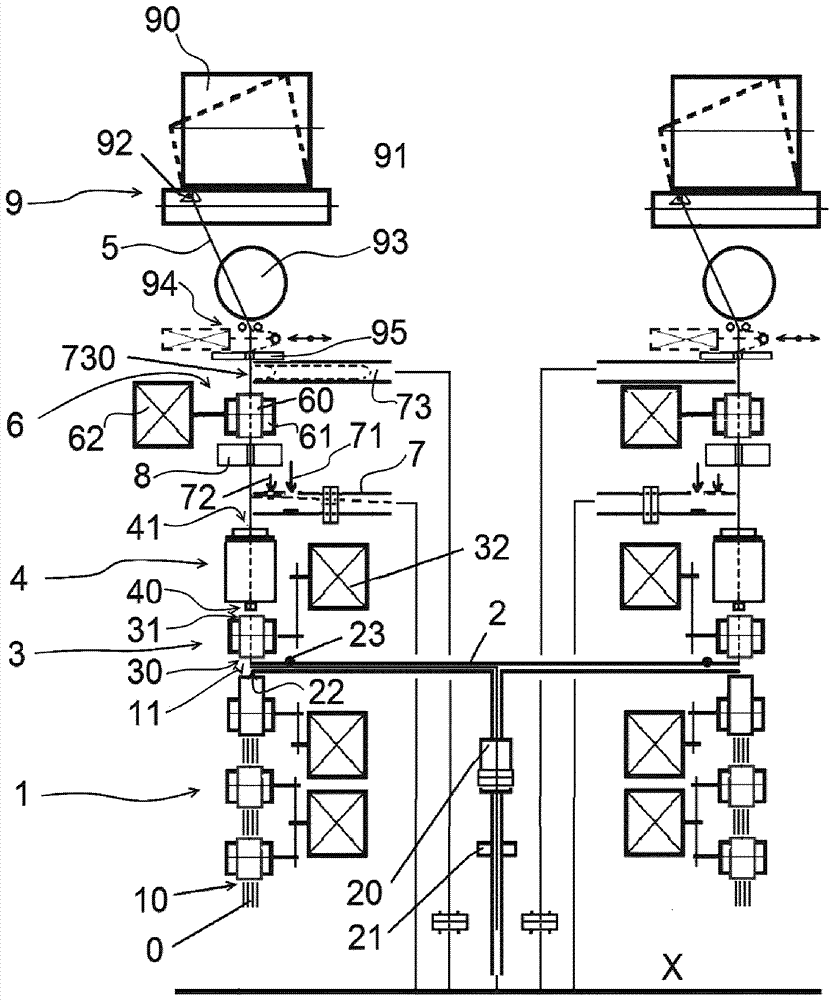

[0016] The invention will be described with respect to an example of an embodiment of a workstation of an air-jet spinning machine comprising at least one row of identical workstations arranged next to each other.

[0017] Workstation including sliver 0 drafting mechanism 1 , the drafting mechanism 1 import 10 aligned with the sliver source not shown and its outlet 11 Feeding device with fibers 3 import 30 aligned, the feeder 3 Connect to drive 32 . fiber feeding device 3 the export 31 with leading to the spinning nozzle 4 entrance of the fiber 40 align. in the spinning nozzle 4 In, the incoming sliver 0 convert to yarn 5 , arranged in the yarn 5 the exit opening 41 rear pulling mechanism 6 from the spinning nozzle 4 to pull 4 yarn 5 .

[0018] Pulling mechanism 6 includes a pair of rollers 60 , 61 , the pair of rolls 60 , 61 pressed towards each other, wherein one of their rollers is coupled to a rotary drive 62 And another roller is rotatably moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com